A bubble pump structure

A technology of bubble pump and hose, applied in the field of pump structure, can solve problems such as difficulties in making pumps, inability to make full use of advantages, and large size gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

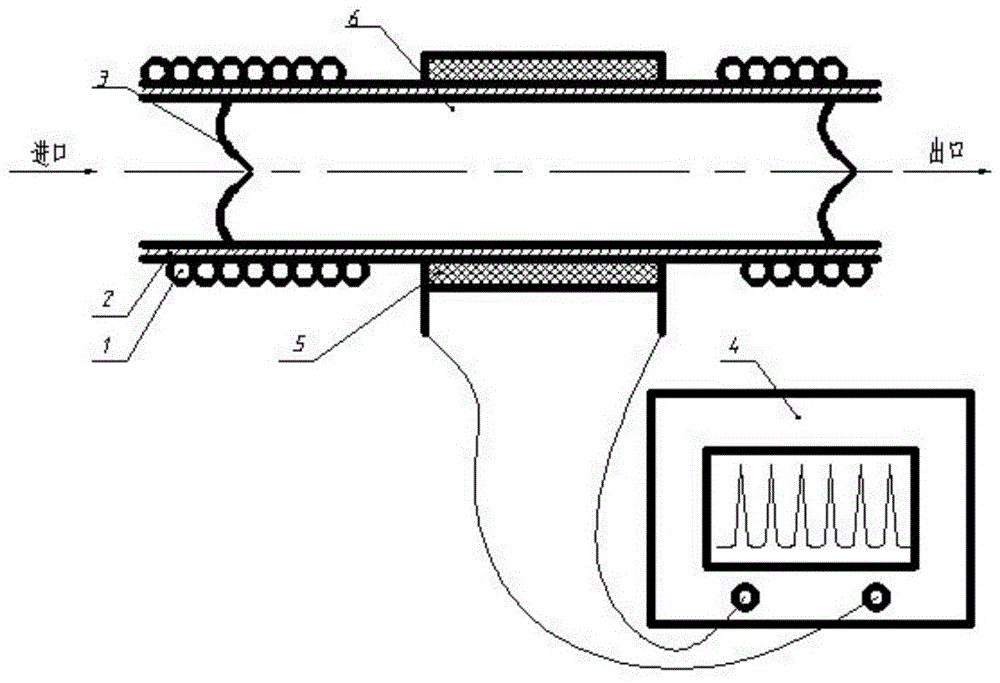

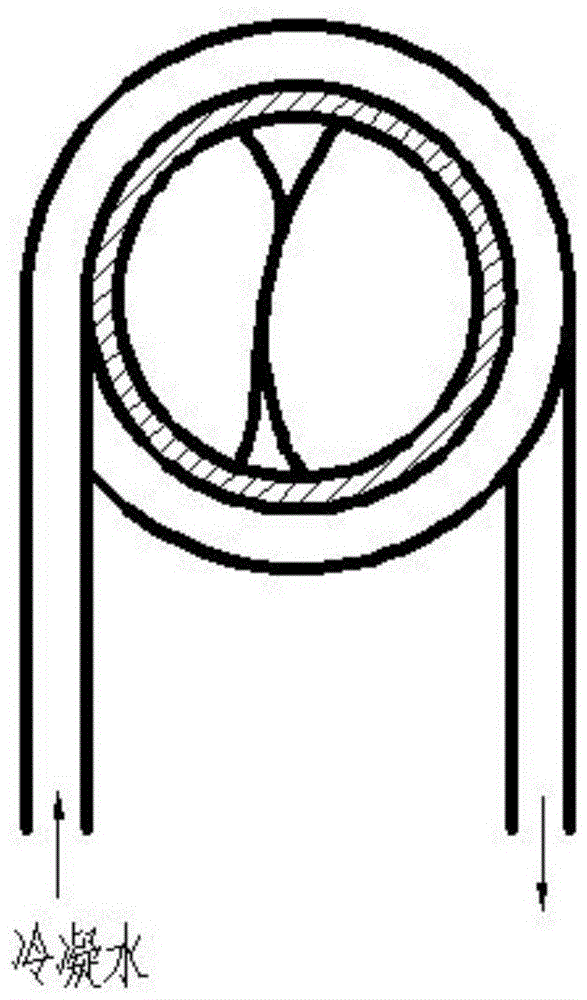

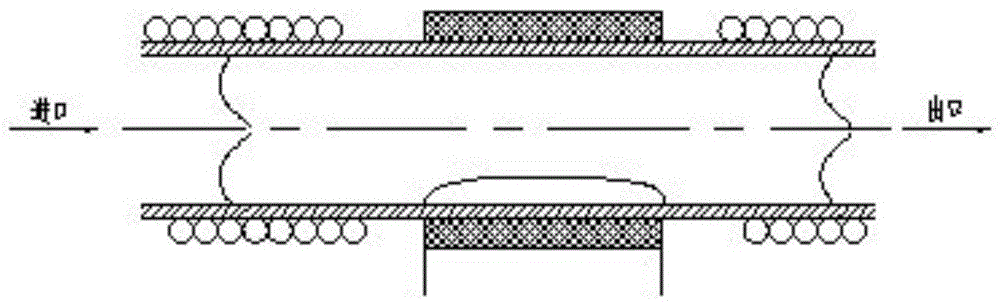

[0012] The structure diagram of the present invention is as figure 1 and Figure 1-A shown. The present invention is mainly designed by using the pressure change caused by the volume change of the positive displacement pump to realize the working principle of pumping and discharging liquid. As shown in Figure 2, the pulse signal generator first adds a voltage pulse to the thin film resistance heater, so that It heats the liquid in the tube. Due to the high heat flux density, the heating speed is extremely fast. In a short time, the liquid near the surface of the heater is heated up rapidly, reaching its boiling temperature, and the liquid is vaporized to form bubbles, as shown in Figure 2 -As shown in Figure 2-A; at this time, the pulse signal disappears, and the bubble expands rapidly under the control o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com