sagd production method of heavy oil reservoir

A technology of heavy oil reservoirs and production methods, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., can solve the problems that the steam injection pressure control measures have not been elaborated in detail, and have not been considered, so as to reduce the production cost, Reduce the injection volume and eliminate the effect of lowering the oil-steam ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

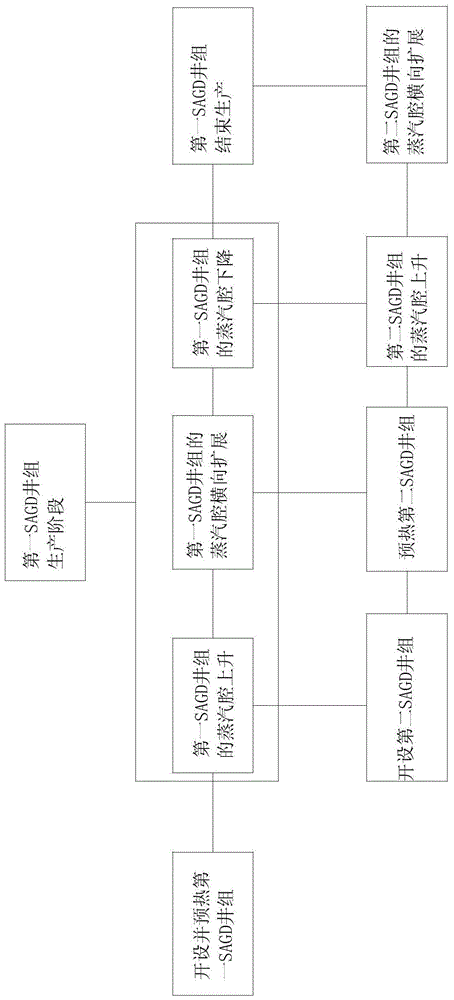

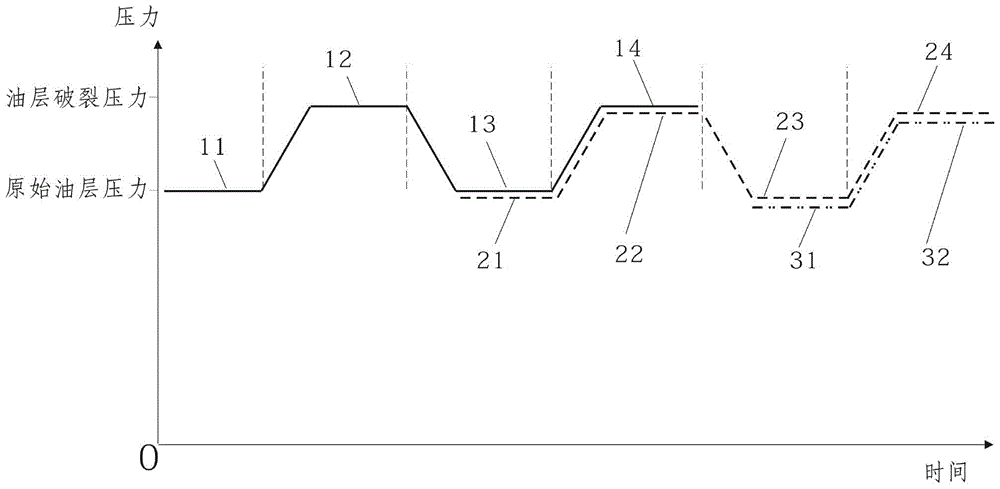

[0075] refer to Figure 1-Figure 3 As shown, a heavy oil reservoir SAGD production method, the heavy oil reservoir is an undeveloped heavy oil reservoir, the average buried depth is 300m, the original reservoir pressure is 2.8MPa, the fracture pressure of the oil layer is 6MPa, and the thickness of the oil layer is The effective average is 26m, which is suitable for deploying SAGD well group scale development.

[0076] The heavy oil reservoir SAGD mining method provided in this embodiment includes the following specific steps:

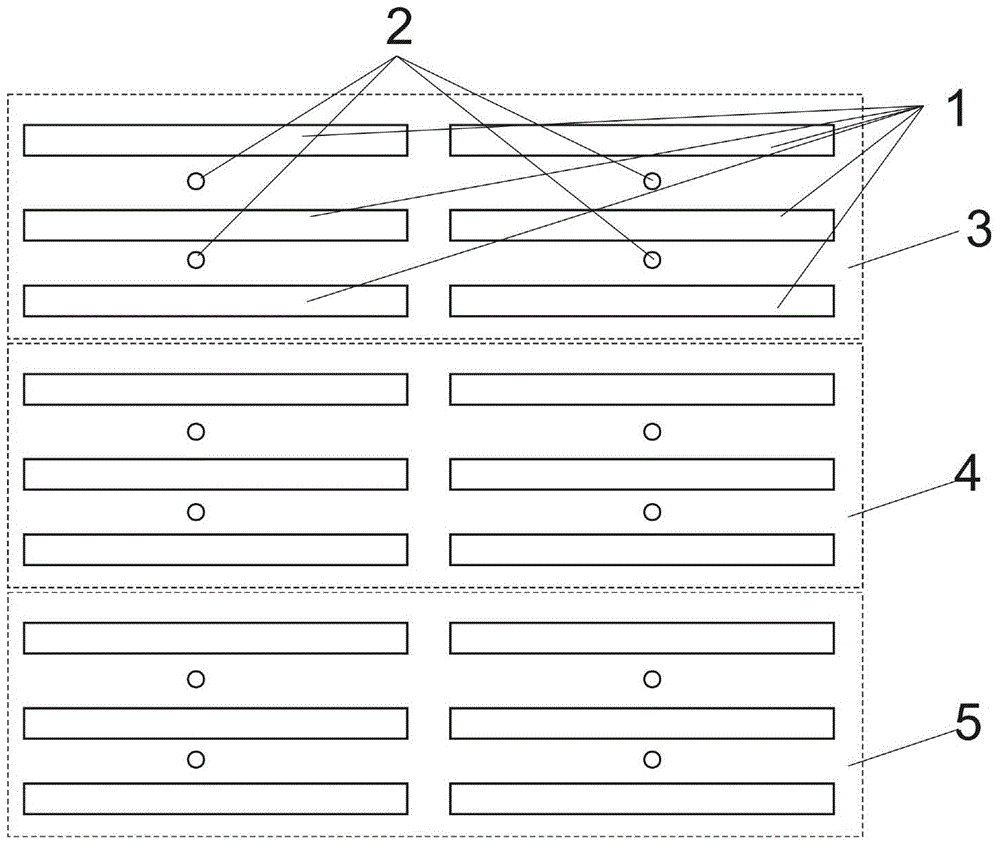

[0077] refer to figure 2 As shown, the first SAGD well group 3 is deployed in the production area of the heavy oil reservoir, and the first SAGD well group 3 includes the SAGD well pair 1 and the monitoring well 2 . Each SAGD well pair is composed of one injection well and one production well, wherein the injection well and the production well are horizontal wells whose horizontal sections are parallel to each other and overlap each other up and d...

Embodiment 2

[0101] refer to Figure 1-Figure 3 As shown, a heavy oil reservoir SAGD production method, the heavy oil reservoir is an undeveloped heavy oil reservoir, the average buried depth is 500m, the original reservoir pressure is 4.8MPa, the fracture pressure of the oil layer is 10MPa, and the thickness of the oil layer is The effective average is 34m, which is suitable for deploying SAGD well group scale development.

[0102] The heavy oil reservoir SAGD mining method provided in this embodiment includes the following specific steps:

[0103] refer to figure 2 As shown, the first SAGD well group 3 is deployed in the production area of the heavy oil reservoir, and the first SAGD well group 3 includes the SAGD well pair 1 and the monitoring well 2 . Each SAGD well pair is composed of one injection well and one production well, wherein the injection well and the production well are horizontal wells whose horizontal sections are parallel to each other and overlap each other up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com