Composite structure of top plate waterproof pavement layer of underground road under shallow burial soil

A composite structure and pavement technology, applied in roads, roads, infrastructure engineering, etc., to achieve the effect of improving integrity and effectiveness, excellent waterproof performance and ability to resist impact loads, and delaying development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

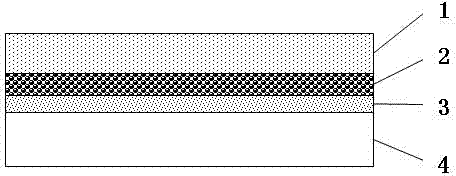

[0013] In the waterproof pavement layer composite structure of the roof under the shallow covering soil of the present invention, the structural layers from top to bottom are cement concrete protective layer 1-synchronous crushed stone seal layer 2-epoxy resin waterproof layer 3-cement concrete roof 4.

[0014] - Epoxy resin waterproof layer 3 adopts epoxy resin waterproof coating, which can effectively penetrate into the surface of the base layer, not only can seal the concrete roof, prevent the moisture in the concrete from rising to the base layer surface, and play the role of waterproof layer, but also combine with the concrete roof and gravel At the same time, the sealing layer has good bonding performance, and can withstand 180°C paving asphalt layer for a short time. The thickness of the waterproof layer is not less than 2mm.

[0015] Synchronous crushed stone seal layer 2 refers to spraying modified asphalt binder on the above epoxy resin waterproof layer, and then spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com