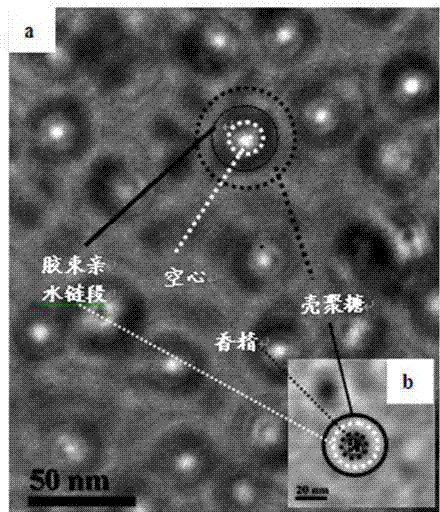

Preparation method of chitosan-based slow-release flavor type nano composite micro-capsule coating material

A nanocomposite and coating material technology, applied in the field of coating materials, can solve problems such as no public reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Prepare a weak acid solution with a mass fraction of 2%, add chitosan powder to it, the mass ratio of chitosan and weak acid solution is 1:10, ultrasonically treat for 20min, and stir at 60°C for 36h to obtain chitosan sugar solution.

[0034] In step 1, the weak acid is acetic acid;

[0035] Chitosan is a water-soluble low molecular weight chitosan with molecular weight within 1000.

[0036] Step 2: Dissolve the amphiphilic copolymer micelle F127 in an organic solvent to form a homogeneous transparent solution. The mass-volume ratio of the amphiphilic copolymer micelle to the organic solvent is 90 mg: 900 μL; after stirring for 8 hours, add the nanoparticle precursor to it and fragrance molecules, ultrasonic treatment for 30min, the mass-volume-mass ratio of the amphiphilic copolymer micelles to the nanoparticle precursor and the fragrance is 9g:9μL:1mg, and a mixed solution is obtained.

[0037] In step 2, the organic solvent is tetrahydrofuran;

[0038] Th...

Embodiment 2

[0042] Step 1: Prepare a weak acid solution with a mass fraction of 3%, add chitosan powder to it, the mass ratio of chitosan to weak acid solution is 1:10, ultrasonically treat for 30min, and stir at 80°C for 54h to obtain chitosan sugar solution.

[0043] In step 1, the weak acid is acetic acid;

[0044] Chitosan is a water-soluble low molecular weight chitosan with molecular weight within 1000.

[0045] Step 2: Dissolve the amphiphilic copolymer micelles F127 in an organic solvent to form a uniform transparent solution. The mass-volume ratio of the amphiphilic copolymer micelles to the organic solvent is 120 mg: 1350 μL; after stirring for 11 hours, add the nanoparticle precursor to it and essence molecules, sonicated for 55min, the mass-volume-mass ratio of the amphiphilic copolymer micelles to the nanoparticle precursor and the essence was 12g:12μL:2mg, and a mixed solution was obtained.

[0046] In step 2, the organic solvent is tetrahydrofuran;

[0047]The nanopartic...

Embodiment 3

[0051] Step 1: Prepare a weak acid solution with a mass fraction of 4%, add chitosan powder to it, the mass ratio of chitosan and weak acid solution is 1:10, ultrasonically treat for 40min, and stir at 100°C for 72h to obtain chitosan sugar solution.

[0052] In step 1, the weak acid is hydrochloric acid;

[0053] Chitosan is a water-soluble low molecular weight chitosan with molecular weight within 1000.

[0054] Step 2: Dissolve the amphiphilic copolymer micelles F127 in an organic solvent to form a uniform transparent solution. The mass-volume ratio of the amphiphilic copolymer micelles to the organic solvent is 150 mg: 1800 μL; after stirring for 14 hours, add the nanoparticle precursor to it and essence molecules, sonicated for 80min, the mass-volume-mass ratio of the amphiphilic copolymer micelles to the nanoparticle precursor and the essence was 15g: 16μL: 3mg, and a mixed solution was obtained.

[0055] In step 2, the organic solvent is dimethylformamide;

[0056] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com