A kind of preparation method of washable piece dyed knitted fabric

A technology for knitted fabrics and production methods, which is applied to textiles and papermaking, mercerization of indefinite length fabrics, biochemical fiber treatment, etc., can solve the problems of increasing the difficulty and difficulty of enzymatic washing, and achieve a favorable penetration effect, eliminate internal stress, The effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

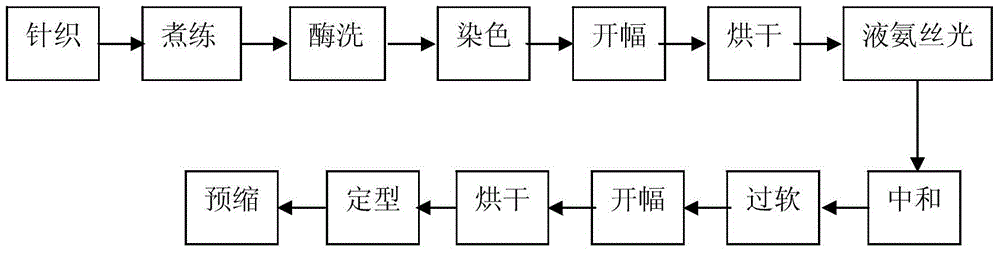

[0044] This embodiment provides a method for manufacturing a washable piece-dyed knitted fabric to produce a 50S / 1 double-sided (Interlock) fabric with a width of 58 inches and a weight of 190GM, CPI=90, WPI=55, such as figure 1 As shown in the process flow, it includes the following steps:

[0045] Knitting: Use 50S / 1 grey yarn to weave the stock according to 32G33”50C=129MM;

[0046] Scouring: With a bath ratio of 1:10, the use of 2g / L refining agent can stabilize ONE (Huntsman Chemical Trading Co., Ltd.), 2g / L NaOH with a mass concentration of 50%, and 3.6g / L specification of 27.5% H 2 O 2 The treatment agent of the solution is scoured under the conditions of a treatment temperature of 95°C and a treatment time of 45 minutes;

[0047] Enzyme washing: at a bath ratio of 1:10, using a washing solution containing 2.5g / L cellulose fiber enzyme (Cellusoft combi, Novozymes China Biotechnology Co., Ltd.) and adjusting the pH to 4.5-5.0 with NaAC and HAC. Enzyme washing is performed unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com