Co-production system for methanol and deeply processed ethanol gasoline and use method of co-production system

A technology of ethanol gasoline and methanol, which is applied in chemical instruments and methods, gasification technology, petroleum industry, etc., and can solve the problems of inability to adjust, large investment in the fertilizer industry, and high transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

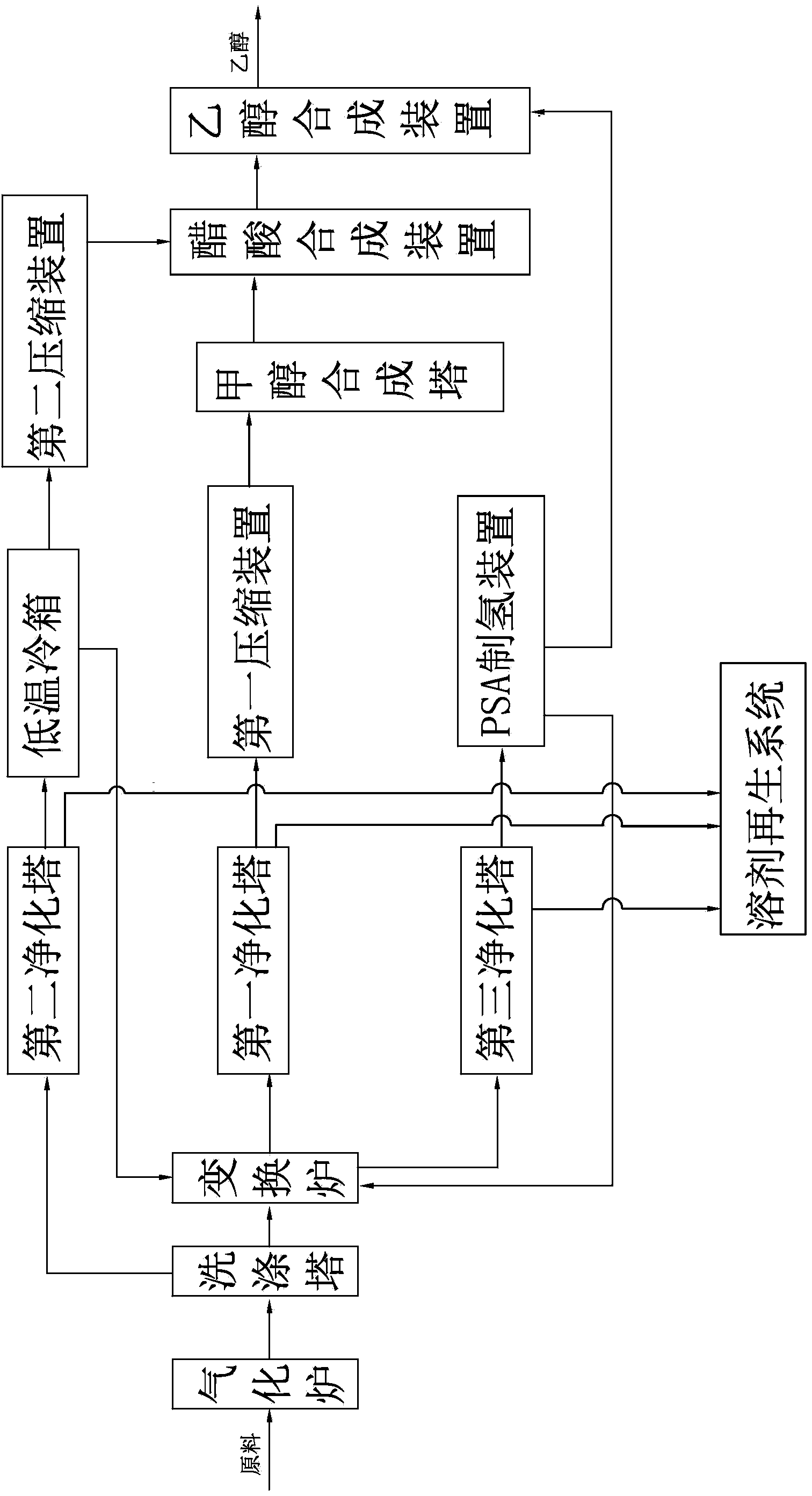

[0026] Such as figure 1 As shown, the co-production system of methanol and deep-processed ethanol gasoline of the present invention includes a gasification furnace, a washing tower, a shift furnace, a first purification tower, a first compression device, a methanol synthesis tower, an acetic acid synthesis device and an ethanol synthesis device in series; The washing tower is also connected in series with a second purification tower, a low-temperature cold box, and a second compression device, and the second compression device is connected with the acetic acid synthesis device; the conversion tower is also connected in series with a third purification device, a PSA Hydrogen production device, the outlet of the PSA hydrogen production device is connected to the ethanol synthesis device, the tail gas outlet of the PSA hydrogen production device is connected to the shift furnace, and the tail gas outlet of the low-temperature cold box is connected to the shift furnace ; The syste...

Embodiment 2

[0031] A method for co-production of methanol and deep-processed ethanol gasoline, comprising the steps of:

[0032] (1) raw material is coal or coal-water slurry, and described coal is the dry coal powder that particle size is controlled between 8 mesh-325 mesh after being crushed by holding mill, and the concentration of described coal-water slurry is 60% (percentage by weight) The raw material is gasified in a gasification furnace, the temperature of the gasification furnace is 50°C higher than the melting point of the raw material, and the operating pressure is 6.5-8.7Mpa; the reacted gas is washed by a washing tower to remove entrainment Coal particles and dust are obtained after the raw synthesis gas, which includes more than 76% by volume of CO and H 2 effective gas, the rest is CO 2 , N 2 、CH 4 , Ar, H 2S, the crude synthesis gas is divided into three parts, which are used to produce CO, methanol and H 2 ;

[0033] The part used to produce CO directly enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com