A kind of flame-retardant plastic coating and preparation method thereof

A technology for flame-retardant plastics and coatings, applied in fire-resistant coatings, polyester coatings, coatings, etc., can solve the problems of insufficient coating adhesion, short service life, poor flame-retardant performance, etc., and achieve low cost, excellent adhesion performance, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

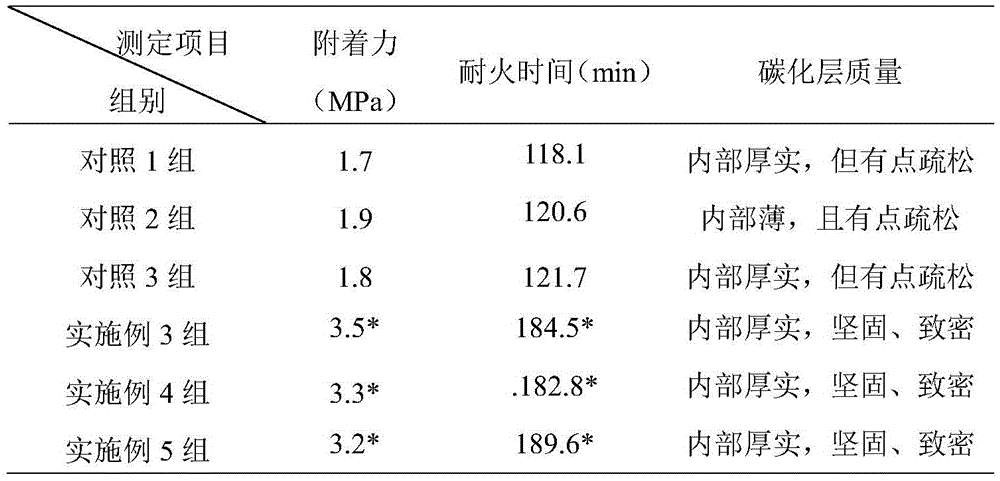

Examples

Embodiment 1

[0018] Party:

[0019] 20g water-based acrylic resin, 10g polystyrene, 2g polylactate, 4g zinc stearate, 1g sodium lauryl sulfonate, 2g dibutyl phthalate, 6g pentaerythritol, 0.5g pigment, 1g talcum powder .

[0020] Preparation:

[0021] (1) Put polystyrene and polylactate in a container, add sodium dodecylsulfonate and a certain amount of deionized water, disperse at a high speed of 4000r / min for 30 minutes, and obtain the first emulsion;

[0022] (2) Add zinc stearate, dibutyl phthalate, pentaerythritol and pigments to the above-mentioned primary emulsion, and disperse at a high speed of 3600r / min for 20 minutes to obtain a color slurry;

[0023] (3) Mix water-based acrylic resin, talcum powder and the above-mentioned color paste, disperse at a low speed of 800r / min for 10 minutes, and the product is obtained.

[0024] The degree of polycondensation of the water-based acrylic resin is 40.

Embodiment 2

[0026] Party:

[0027] Water-based acrylic resin 20g, polystyrene 20g, polylactate 12g, zinc stearate 10g, sodium lauryl sulfonate 5g, dibutyl phthalate 8g, pentaerythritol 12g, pigment 0.9g, glass powder 7g .

[0028] Preparation:

[0029] (1) Put polystyrene and polylactate in a container, add sodium dodecylsulfonate and a certain amount of deionized water, disperse at a high speed of 6000r / min for 40 minutes, and obtain the primary emulsion;

[0030] (2) Add zinc stearate, dibutyl phthalate, pentaerythritol and pigments to the above-mentioned primary emulsion, disperse at a high speed of 4200r / min for 30 minutes, and obtain a color slurry;

[0031] (3) Mix water-based acrylic resin, glass powder and the above-mentioned color paste, and disperse at a low speed of 1200r / min for 20 minutes to obtain the product.

[0032] The degree of polycondensation of the water-based acrylic resin is 60.

Embodiment 3

[0034] Party:

[0035] Water-based acrylic resin 20g, polystyrene 15g, polylactate 7g, zinc stearate 7g, sodium laurylsulfonate 3g, dibutyl phthalate 5g, pentaerythritol 9g, pigment 0.7g, diatomaceous earth 4g.

[0036] Preparation:

[0037] (1) Put polystyrene and polylactate in a container, add sodium dodecylsulfonate and a certain amount of deionized water, and disperse at a high speed of 5000r / min for 35 minutes to obtain the first emulsion;

[0038] (2) Add zinc stearate, dibutyl phthalate, pentaerythritol and pigments to the above-mentioned primary emulsion, and disperse at a high speed of 3900r / min for 25 minutes to obtain a color paste;

[0039] (3) Mix water-based acrylic resin, diatomaceous earth and the above-mentioned color paste, and disperse at a low speed of 1000r / min for 15 minutes to obtain the product.

[0040] The degree of polycondensation of the water-based acrylic resin is 50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com