A half-ship positioning beam

A technology for pulling beams and ship owners, applied in the direction of berths, ship construction, ship parts, etc., can solve the problems of low positioning accuracy, poor applicability, complex structure, etc., and achieve the effect of improving applicability, low use cost, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

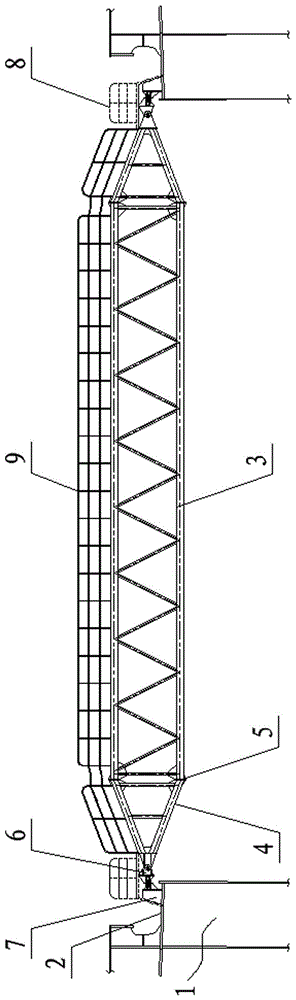

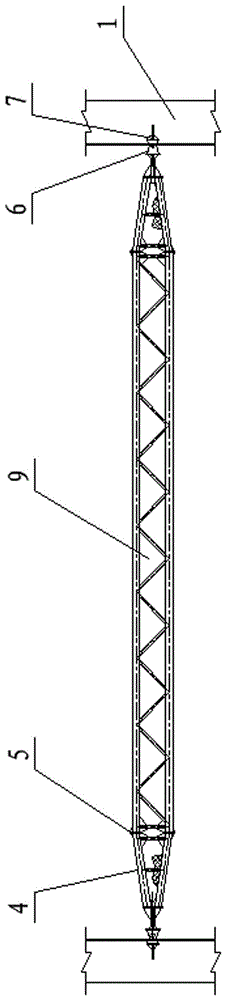

[0017] figure 1 , 2 As shown, a half-ship positioning beam includes an intermediate main girder 3, an end beam 4, a flange 5, an intermediate ear plate 6, a base plate 7 and a bridge 8. The two halves of the ship 1 are provided with a base plate 7 on the relative main deck 2 close to the side shell plate. The base plate 7 is hinged with the vertical direction as the hinge axis to move one end of the lug plate 6, and the other end of the lug plate 6 is used to move forward with the half ship. The direction is the hinge axis and the hinged end beam 4 is movable. The two ends of the beams 4 at both ends are connected to the two ends of the middle main beam 3 through the flange 5. The middle main beam 3 is provided with a safety passage 9 with a guardrail. The main deck of the two halves of the ship 1 2 is provided with a bridge 8 connecting the main deck 2 and the safety pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com