Concave and convex transfer printing chemical fiber fabrics and production process device and method thereof

A chemical fiber fabric, transfer printing technology, applied in the field of textile printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below with reference to accompanying drawing, through the description of specific embodiment, the present invention will be further described,

[0045] One of a typical specific implementation manner.

[0046] A printed chemical fiber fabric with concave-convex transfer printing. On the surface of the chemical fiber fabric 1, there are colored flower patterns 2 in a concave-convex three-dimensional structure.

[0047] The flower pattern 2 on the surface of the chemical fiber fabric 1 is in the shape of a three-dimensional sculpture, and the flower pattern 2 is a mixture of one or more of text patterns, flower, bird and animal patterns, building patterns, and landscape patterns. pattern.

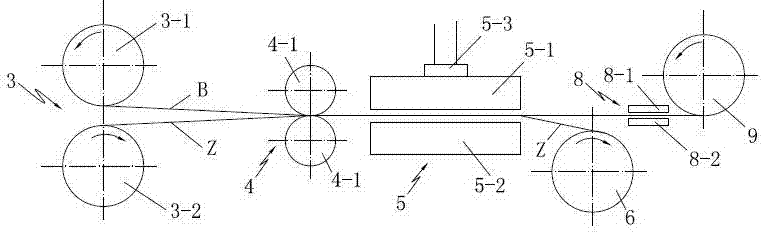

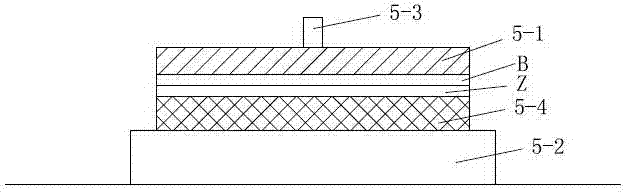

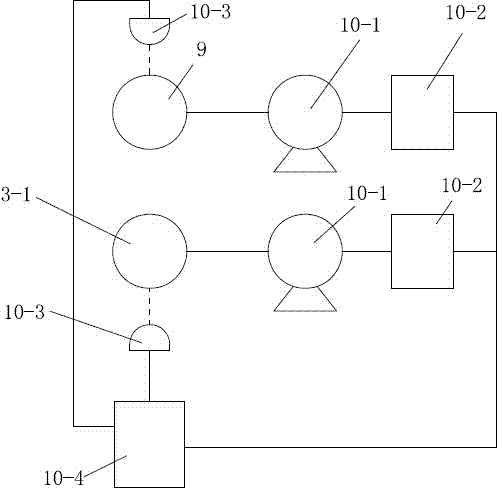

[0048] A typical specific implementation mode two, please refer to the attached figure 1 , 2 , 3, 4 and 5.

[0049] A production process equipment for preparing printed chemical fiber fabrics as described in one of the embodiments, comprising:

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com