A 3D printing device with a rotary digital valve

A 3D printing, digital valve technology, applied in the field of rapid prototyping devices, can solve the problems of liquid dripping, restricting printing efficiency, affecting printing accuracy, etc. The effect of motor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

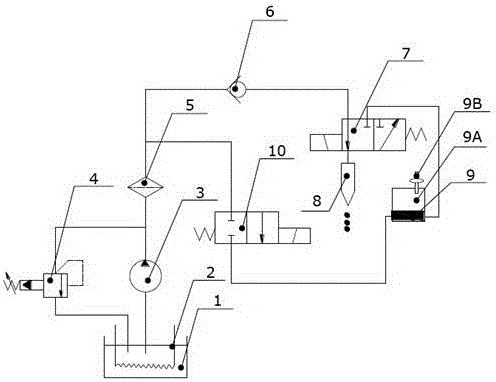

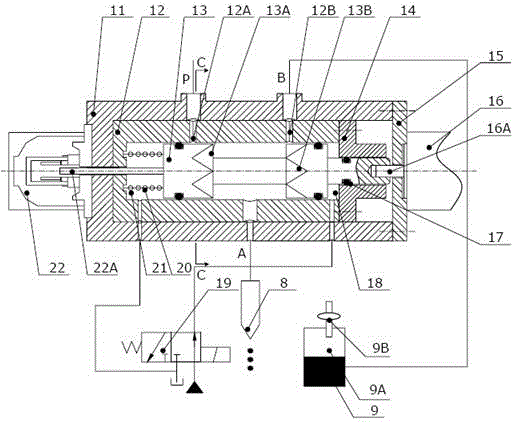

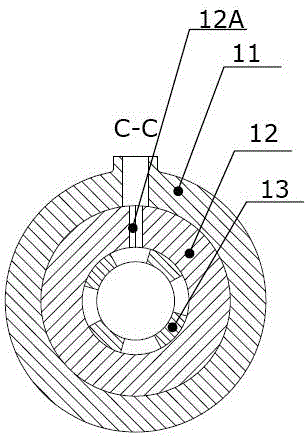

[0036] Such as figure 1 as shown, figure 1 It shows the overall structure of the embodiment of the present invention with the rotary digital valve 7 in the 3D printing injection system. In the system, materials are placed in the main material box 1 with a heating device 2 for heating to meet the spraying conditions. When the rotary digital valve 7 works in the left position, the material passes through the main material box 1, the pump 3, the filter 5, the one-way valve 6, the rotary digital valve 7, and then is ejected from the printing nozzle 8; the rotary digital valve 7 is the key component of the printing injection system. The output of discrete liquid is realized through the rotation of the valve core 13. During the working process of the injection system, in order to avoid the phenomenon of liquid dripping under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com