Punching machine capable of automatically controlling punching depth

A punching machine and depth technology, applied in the direction of boring/drilling, drilling/drilling equipment, manufacturing tools, etc., can solve problems such as low production efficiency, hidden safety hazards, and high labor intensity of workers, so as to reduce wear and tear , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

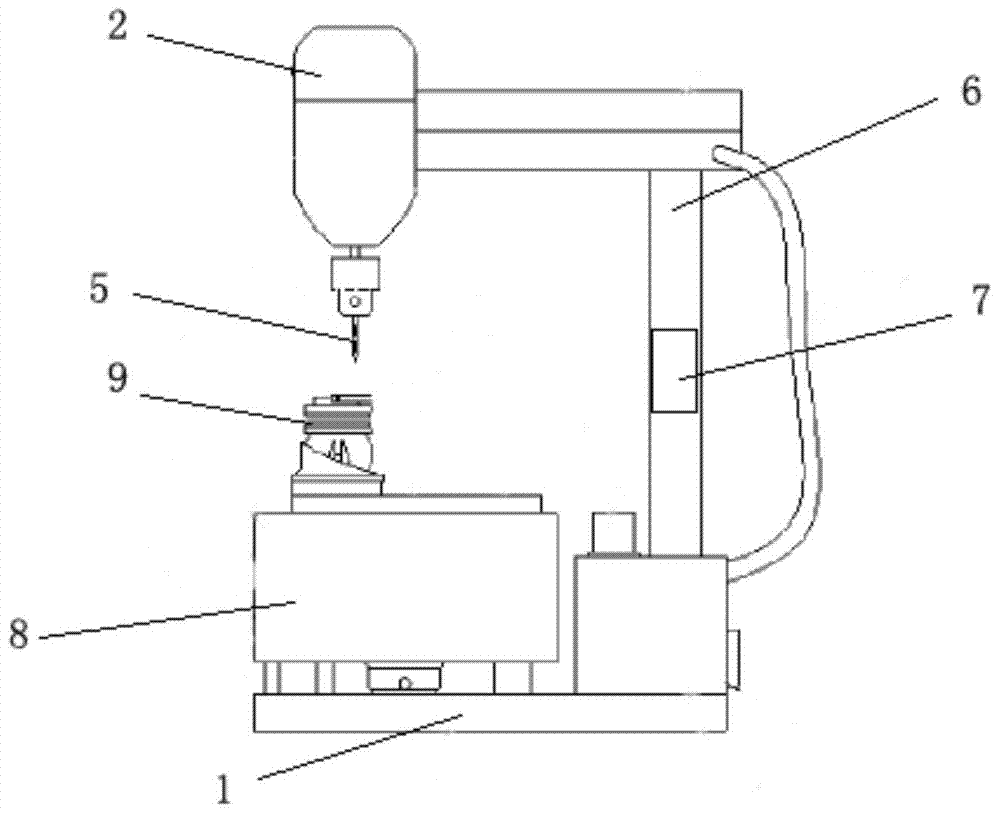

[0016] A drilling machine for automatically controlling the drilling depth, comprising a base 1, a motor 2 and a control device, the power output shaft 3 of the motor 2 is connected with an internal cooling joint 4, the internal cooling joint 4 is connected with a hollow drill bit 5, and the base 1 is provided with There is a support 6, on which a lifting cylinder 7 is arranged, the lifting cylinder 7 is connected to the control device, the motor 2 is fixedly connected to the support 6, a workbench 8 is also arranged on the base 1, and a clamping mechanism 9 is arranged on the workbench 8 .

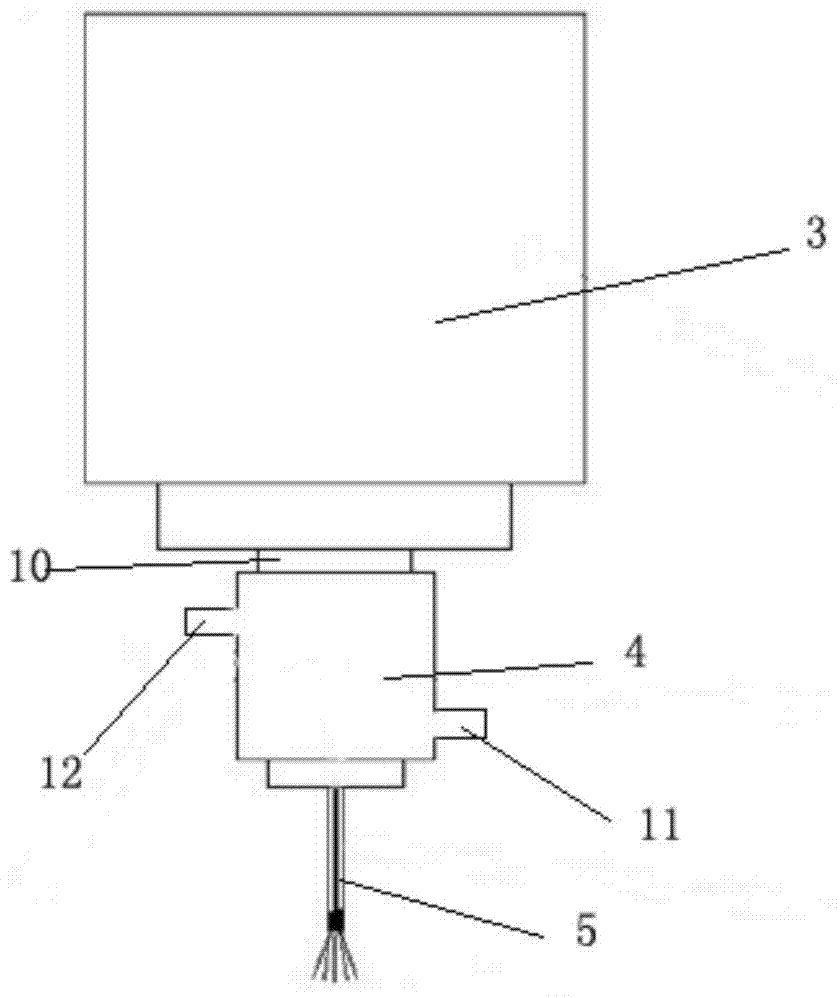

[0017] The internal cooling joint 4 is composed of a main shaft 10, a water inlet 11 and a water outlet 12. The upper end of one side of the main shaft 10 is provided with a water outlet 12, and the lower end of the other side of the main shaft 10 is provided with a water inlet 11. The water inlet 11 and the water outlet 12 are connected with the main shaft 10 are connected by sealed bear...

Embodiment 2

[0021] A drilling machine for automatically controlling the drilling depth, comprising a base 1, a motor 2 and a control device, the power output shaft 3 of the motor 2 is connected with an internal cooling joint 4, the internal cooling joint 4 is connected with a hollow drill bit 5, and the base 1 is provided with There is a support 6, on which a lift cylinder 7 is arranged, the lift cylinder 7 is connected to the control device, the motor 2 is fixedly connected to the support 6, a workbench 8 is also arranged on the base 1, and a clamping mechanism 9 is arranged on the workbench 8 .

[0022] The control device includes a PLC controller and a drilling depth input device, the output end of the drilling depth input device is connected to the input end of the PLC controller, and the output end of the PLC controller is connected to the lifting cylinder 7 .

[0023] The clamping mechanism includes a bottom plate and a clamping part, the clamping part is arranged on the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com