Cleaning machine of oil tank trucks

A washing machine and oil tanker technology, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problem of increasing the complexity of the operation of the oil tanker washing machine, increasing the driving source of the oil tanker washing machine, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

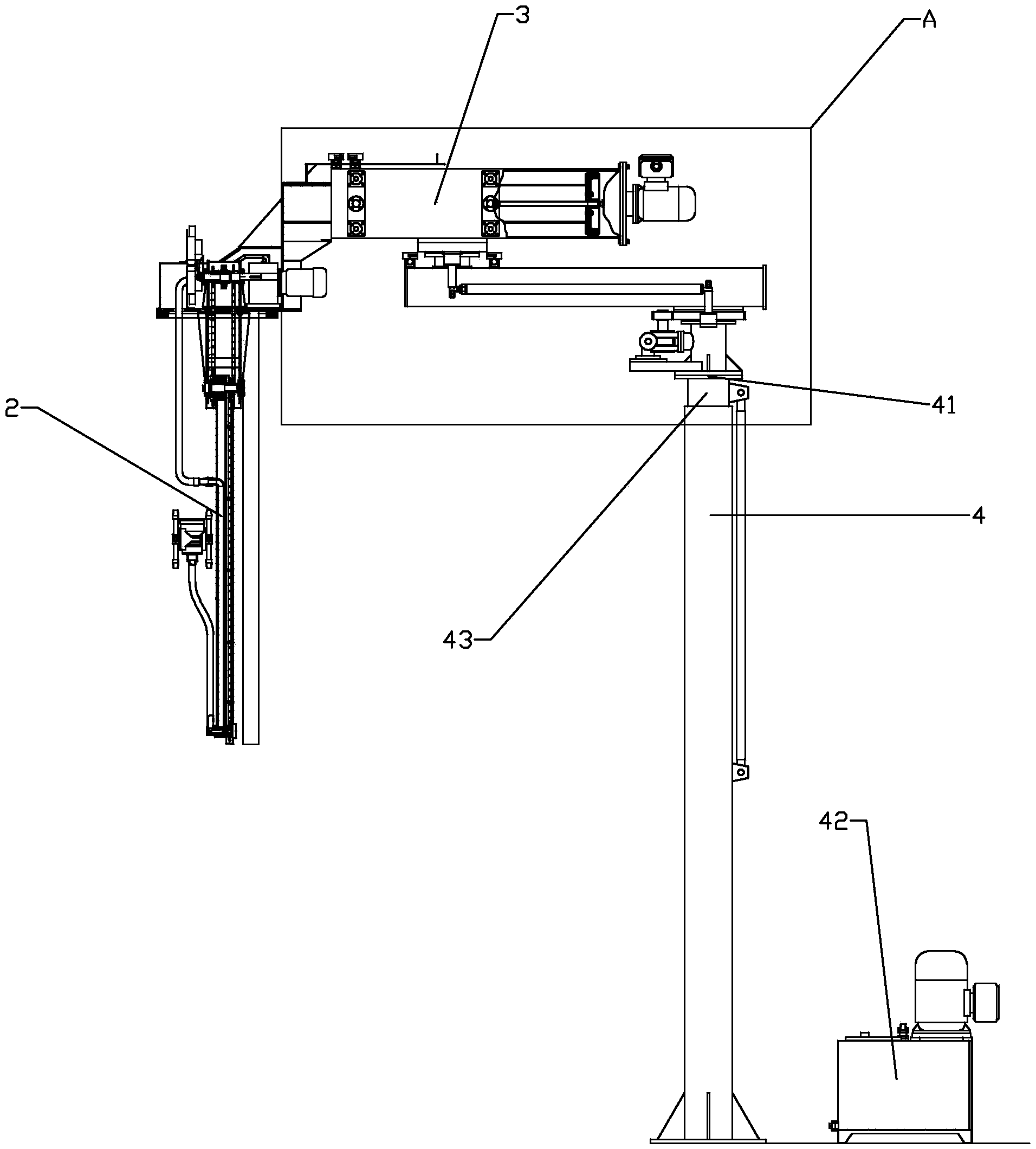

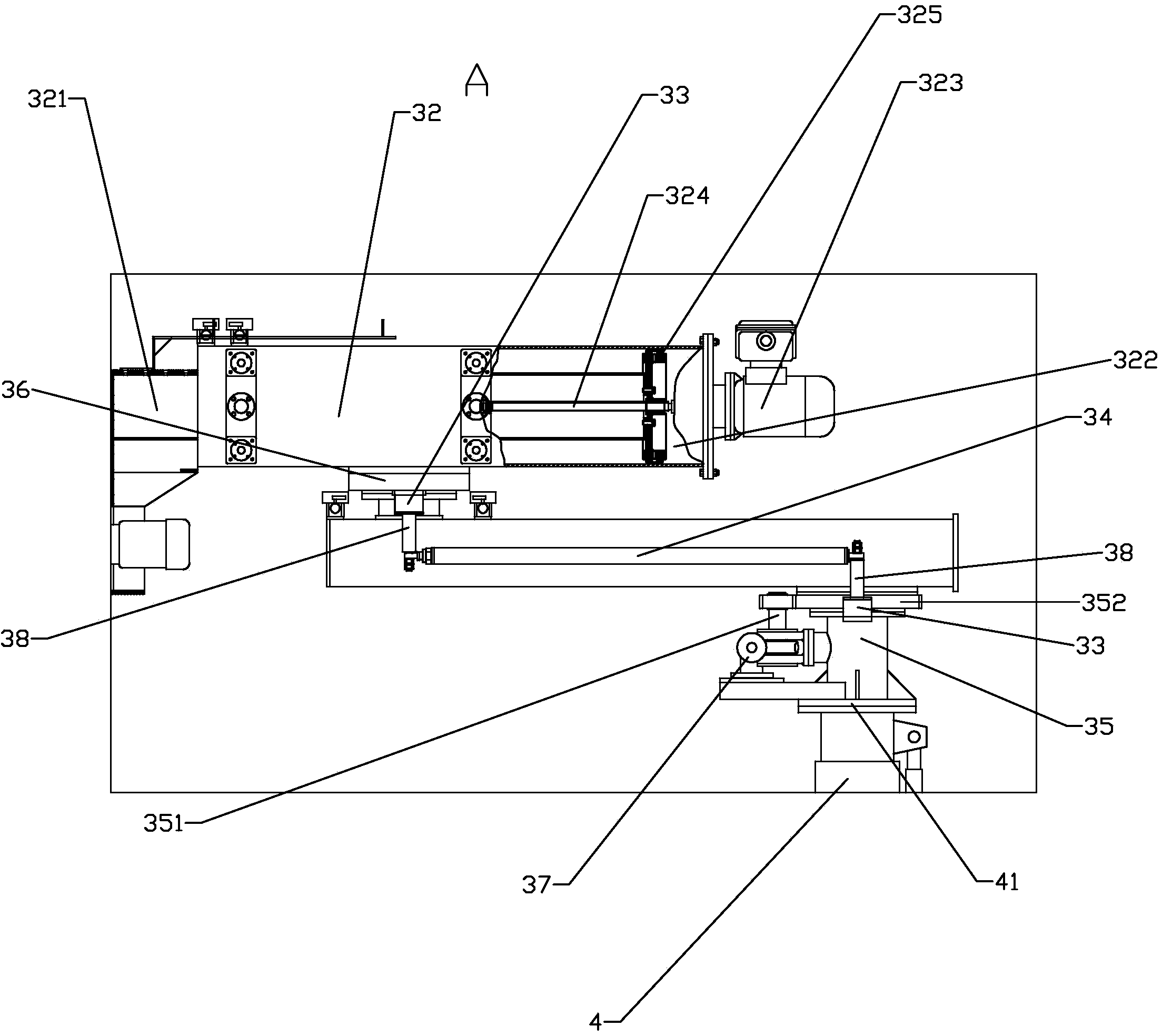

[0030] Such as figure 1 — Figure 6As shown, the present invention discloses an oil tank truck cleaning machine, which includes a base 1, on which a nozzle device 2, a horizontal direction adjustment and distance adjustment mechanism 3 of the nozzle device 2 and a lifting mechanism 4 of the nozzle device 2 are arranged, and the horizontal The steering and distance adjustment mechanism 3 includes a first fork 31 that is horizontally swayed at one end on the lifting platform 41 of the elevating mechanism 4, and a second fork 32 that is horizontally oscillating at the other end of the first fork relative to the lifting platform 41 and A swing driving mechanism that drives the first swing rod 31 and the second swing rod 32 to swing horizontally. The spray head device 2 is fixedly installed on the end of the second swing rod 32 away from the first swing rod 31. The first swing rod 31 is horizontally and parallelly arranged with The main linkage rod 34, the two ends of the main li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com