Array electrostatic-atomization ultrafine particulate matter coalescence equipment and method

An electrostatic atomization, ultra-fine technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of inability to handle ultra-fine particles, poor stability of separation devices, increase system resistance, etc., to increase the overall Surface area, low cost, effect of enhancing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

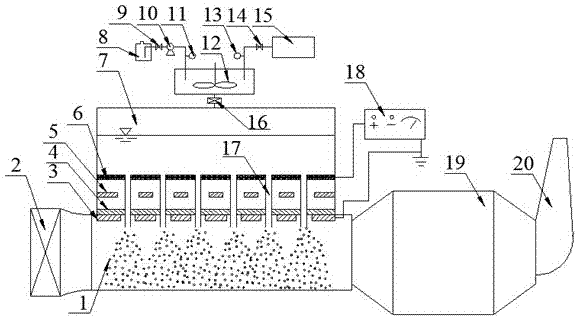

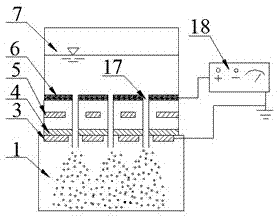

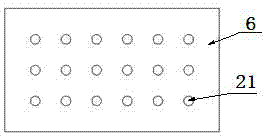

[0019] see figure 1 with figure 2 , an array type electrostatic atomization ultrafine particle reunion device of the present invention is equipped with an electrostatic atomization reunion chamber 1 for ultrafine particles, the electrostatic atomization reunion chamber 1 is rectangular, and the front end of the electrostatic atomization reunion chamber 1 is connected to the flue gas inlet 2. The rear end of the electrostatic atomization agglomeration chamber 1 is connected to a conventional dust collector 19 , and the rear end of the dust collector 19 is connected to an exhaust chimney 20 . The airflow containing smoke enters the electrostatic atomization agglomeration chamber 1 from the flue gas inlet 2, and the flue gas formed after electrostatic atomization agglomeration or agglomeration treatment in the electrostatic atomization agglomeration chamber 1 is output to the dust collector 19, and then discharged from the chimney 20 .

[0020] An array type electrostatic atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com