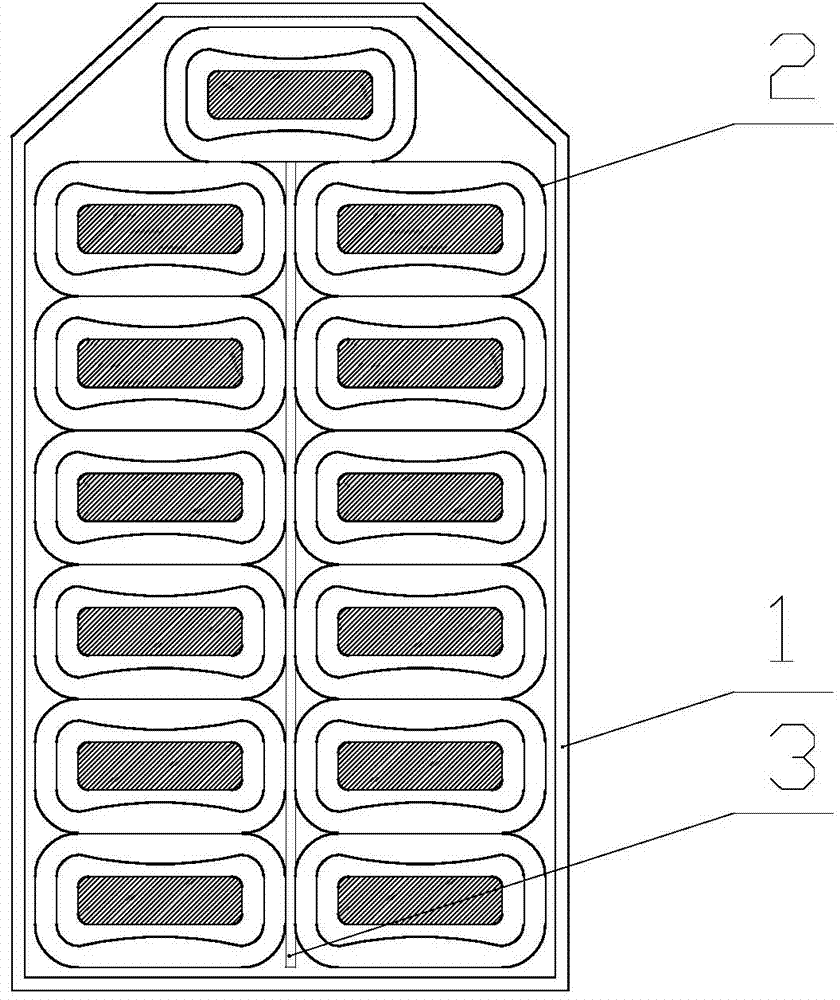

Heat-resistant self-sticking transposed conductor for transformers and manufacturing method thereof

A transposition wire, transformer technology, applied in the direction of transformer/inductor coil/winding/connection, cable/conductor manufacturing, conductor, etc., can solve the problem of affecting the safety and service life of transformer operation, the bond strength of self-adhesive transposition wire weakening, transformer winding distortion and other problems, to improve short-circuit resistance, improve mechanical strength, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

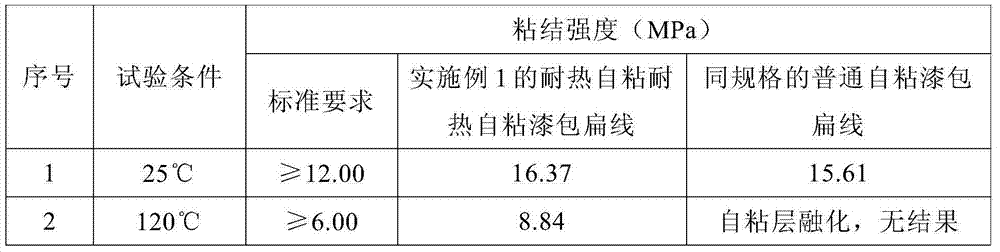

Embodiment 1

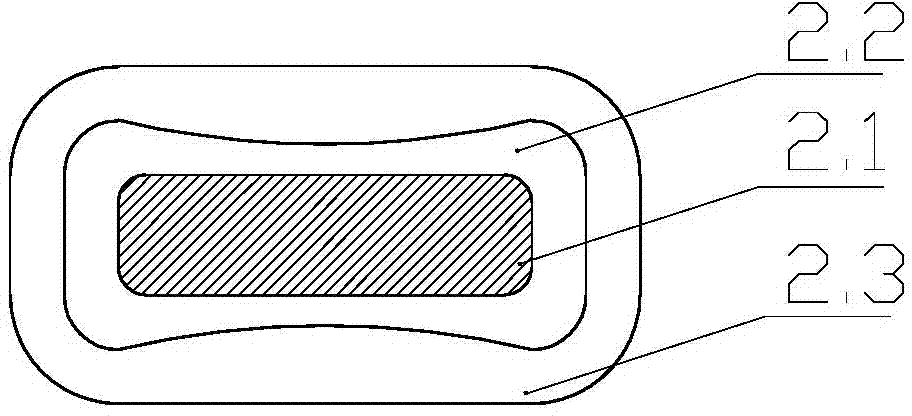

[0027] A kind of preparation method of heat-resistant self-adhesive transposition wire for transformer of the present invention comprises the following steps:

[0028] a. Take the cross-section of the already produced rectangular conductor with rounded corners, the size is 1.40mm×6.07mm, use a concave fixed paint mold to coat the surface of the conductor with primer, and then enter the vertical enamelled oven for baking Curing, the inlet temperature of the vertical enamelling oven is controlled at 130°C-135°C, the temperature of the lower layer is controlled at 235°C-240°C, the temperature of the middle layer is controlled at 350°C-370°C, and the temperature of the upper layer is controlled at 390°C-400°C. The speed is controlled at 10m / min, the primer is solidified to form a primer film with a thickness of 0.09mm, and the indentation of the primer film is 0.010mm, and a heat-resistant self-adhesive enamelled flat wire semi-finished product is obtained;

[0029] b. Use the Hal...

Embodiment 2

[0038] A kind of preparation method of heat-resistant self-adhesive transposition wire for transformer of the present invention comprises the following steps:

[0039] a. Take the cross-section of the already produced rectangular conductor with rounded corners, the size is 1.22mm×5.04mm, use a concave fixed paint mold to coat the surface of the conductor with primer, and then enter the vertical enamelled oven for baking Curing, the inlet temperature of the vertical enamelling oven is controlled at 120°C-125°C, the temperature of the lower layer is controlled at 220°C-230°C, the temperature of the middle layer is controlled at 300°C-310°C, and the temperature of the upper layer is controlled at 380°C-390°C. The speed is controlled at 10.5m / min, the primer is cured to form a primer film with a thickness of 0.08mm, and the indentation of the primer film is 0.010mm, and a heat-resistant self-adhesive enamelled flat wire semi-finished product is obtained;

[0040] b. Use the Half p...

Embodiment 3

[0049] A kind of preparation method of heat-resistant self-adhesive transposition wire for transformer of the present invention comprises the following steps:

[0050] a. Take the cross-section of the already produced rectangular conductor with rounded corners, the size is 2.67mm×12.02mm, use a concave fixed paint mold to coat the surface of the conductor with primer, and then enter the vertical enamelled oven for baking Curing, the inlet temperature of the vertical enamelling oven is controlled at 215°C-220°C, the temperature of the lower layer is controlled at 305°C-310°C, the temperature of the middle layer is controlled at 410°C-420°C, and the temperature of the upper layer is controlled at 440°C-450°C. The speed is controlled at 13m / min, the primer is cured to form a primer film with a thickness of 0.012mm, and the indentation of the primer film is 0.015mm, and a heat-resistant self-adhesive enamelled flat wire semi-finished product is obtained;

[0051] b. Use the Half p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com