Intelligent routing-inspection system of electrical equipment

A technology for power equipment and intelligent inspection, which is applied in the direction of inspection time patrol, etc., can solve problems affecting the quality of power equipment inspection, timely feedback, lack of hardware specification guarantee and standardized specification guidance, hidden dangers of power equipment failure can not be discovered in time and Prevention and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

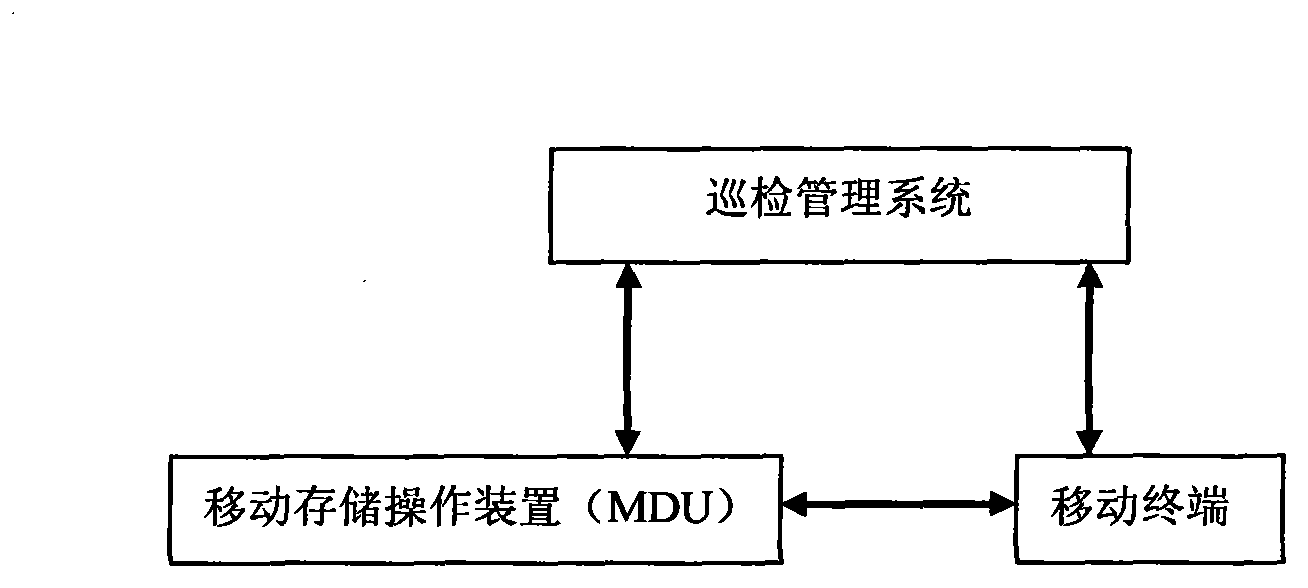

[0026] Example 1, in figure 1In the schematic diagram of the system configuration of the present invention shown, the intelligent inspection system of the present invention includes an inspection management system and a mobile inspection device supporting it, wherein the mobile inspection device includes a mobile terminal and a mobile storage operation device, The inspection management system is used to transmit the inspection task data to the mobile storage operation device (also referred to as MDU), and collect the information of the task execution personnel during the execution of the inspection task or after completing the inspection task. Execution of the inspection task; the mobile storage operation device is used to receive and store the inspection task data, and display it through the mobile terminal to guide the task execution personnel to perform the inspection task. The mobile storage operation device also uses To collect corresponding identity information of electr...

Embodiment 2

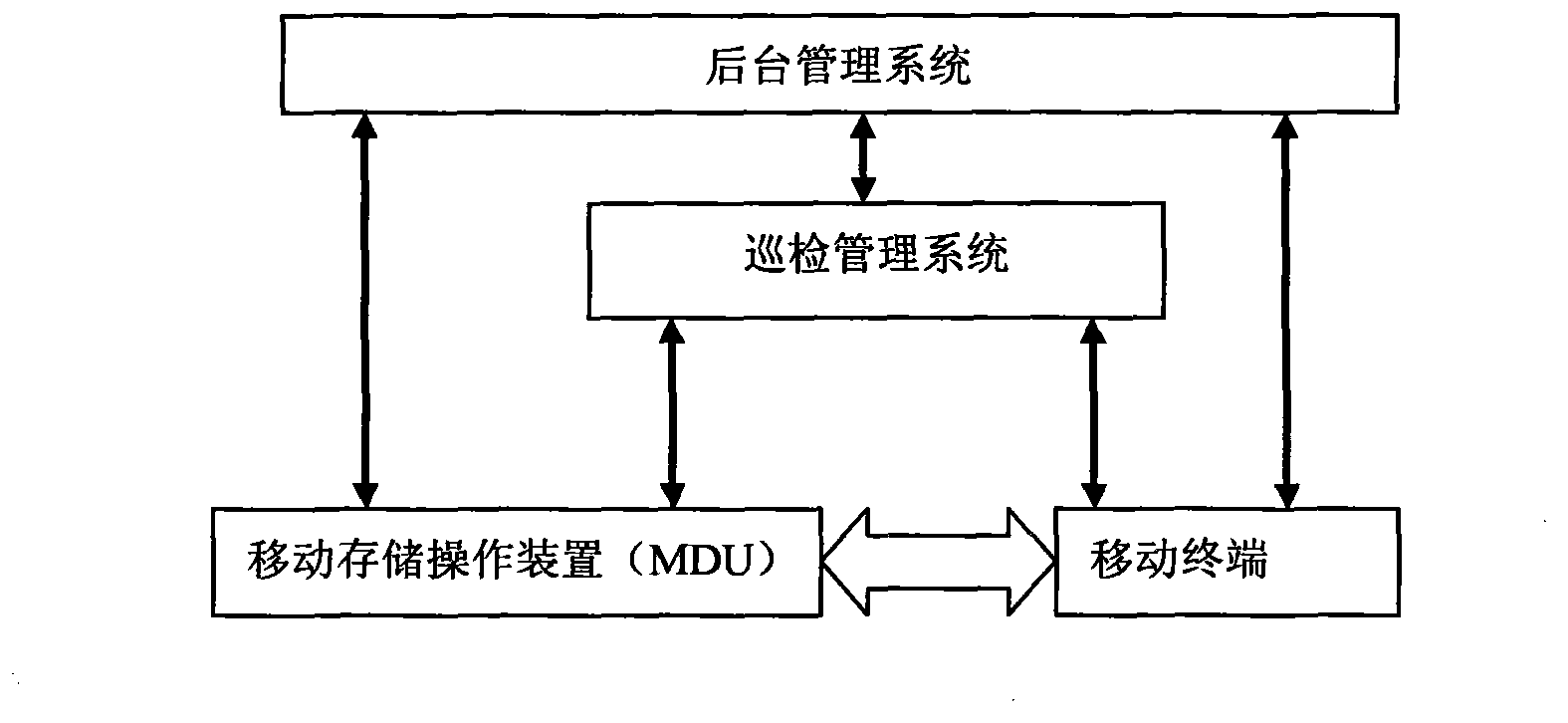

[0028] Embodiment 2, except that the background management system is added in the present invention, other structures and system configurations are the same as those in Embodiment 1. exist figure 2 In the schematic diagram of the system configuration of the present invention shown, the intelligent inspection system of the present invention also includes a background management system. When the inspection management system does not transmit the inspection task data to the mobile storage operation device, if the time And the distance allows, such as a short distance within 300 meters or 100 meters, the background management system can be used to transmit the inspection task data to the mobile storage operation device, and receive the mobile terminal or the inspection management The inspection task execution status of the task executors transmitted by the system. In Embodiment 2, the patrol inspection management system still transmits the patrol inspection task data to the mobi...

Embodiment 3

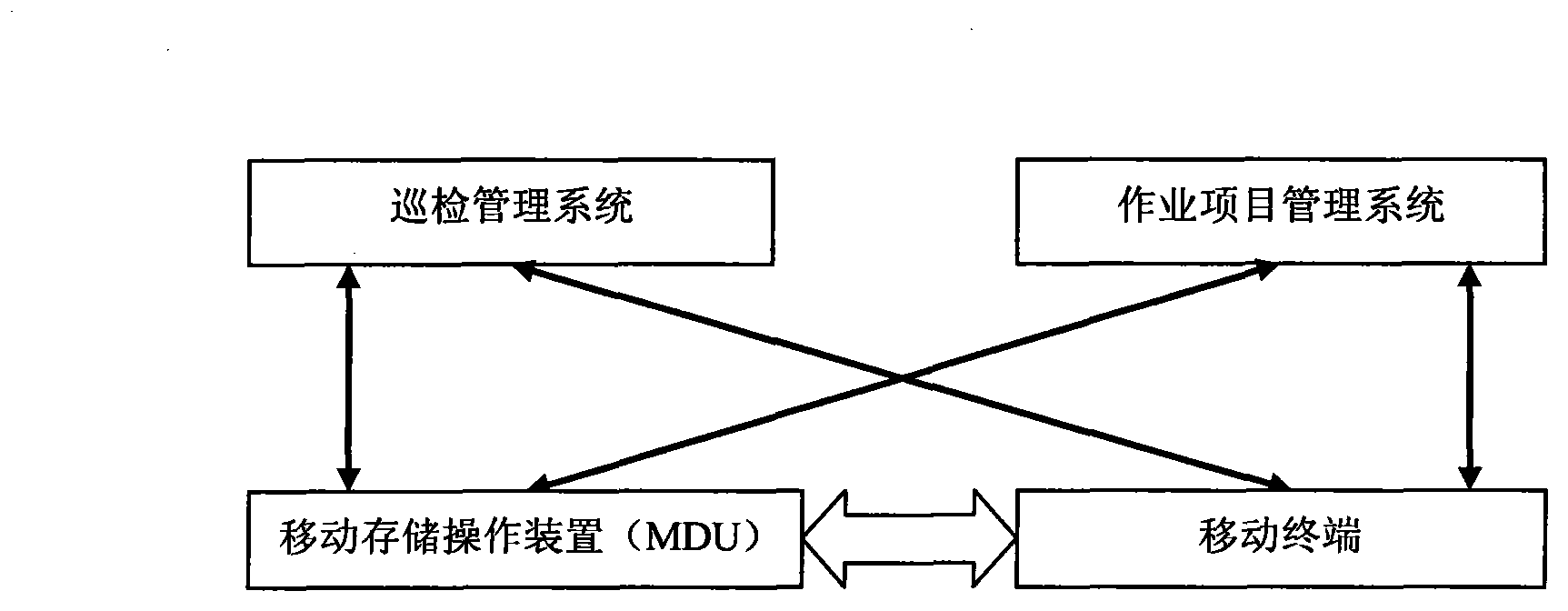

[0029] Embodiment 3, except that the present invention is provided with an operation item management system, other structures and system configurations are the same as those of the system configuration described in Embodiment 1. exist image 3 In the schematic diagram of the system configuration of the present invention shown, the intelligent inspection system of the present invention also includes a work item management system, and the work item management system is used to transmit the work task data to the mobile storage operation device, and receive the Describe the job task execution status report of the task executor transmitted by the mobile terminal. The mobile storage operation device and the mobile terminal transmit the job task data and job task execution status through a wired connection; the job item management system and the mobile storage operation device use a direct plug-in method , to transmit job task data; the job task execution status is that the mobile s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com