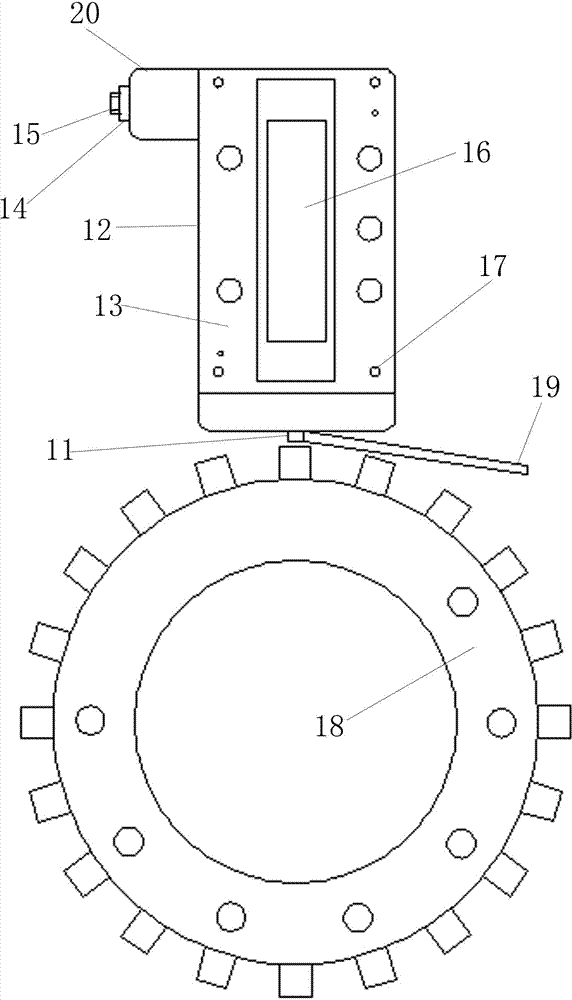

Assembled side-outlet flexible-connection velocity sensor

A technology of speed sensor and side outlet wire, which is applied in the direction of speed/acceleration/shock measurement, speed/acceleration/electric shock meter details, instruments, etc. It can solve the problems of speed sensor contact failure that cannot be reused and maintenance difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An assembled side-outlet soft wire speed sensor, comprising a housing 12 and a sealing plate 13. The housing 12 and the sealing plate 13 are combined to form an internal chamber and a circuit board 16 and a flexible connecting wire 22 are arranged in the chamber; One side of the housing 12 is horizontally provided with a boss 20 near the top surface of the housing 12, and a metal connector 14 is horizontally provided on the boss 20; the cable connected to the circuit board 16 extends through the metal connector 14 The chamber; the inner side of the metal joint 14 and the cable is provided with a sealing rubber sheath 15; the bottom of the housing 12 is installed with a probe 11, the probe 11 is connected to the circuit board 16 through a flexible connecting wire 22; the housing 12 and A layer of sealing sheet 21 is sandwiched between the sealing plates 13.

[0017] The housing 1 has a square or rectangular structure and its front is open, and the inside of the opening is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com