Multi-scale mould for making and simulating structural surface of country rock

A structural surface, multi-scale technology, applied in the engineering field, can solve the problems of inability to prepare structural surface samples of various sizes, and the surface morphology of the structural surface is not representative, achieving great practical value, and the mold principle is simple and easy to understand. Good sample integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] Taking the structural surface sample of simulating 4cm * 4cm * 4cm as an example below, the embodiment of the present invention is illustrated as follows:

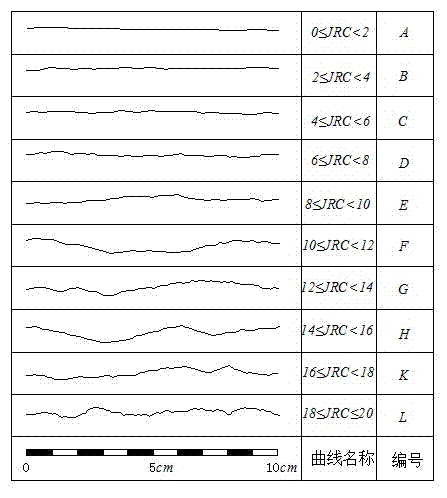

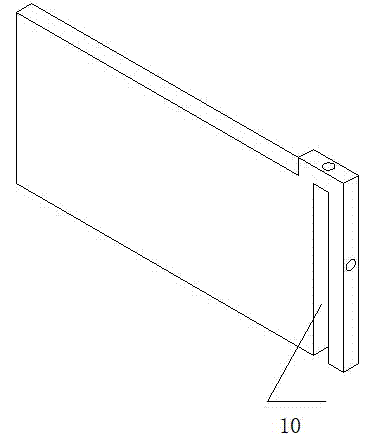

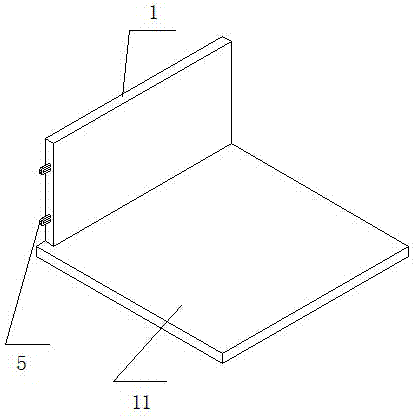

[0033] According to the size of the structural surface to be simulated, move the card slot on the C-type outer plate to the position where the scale of the A-type outer plate is 5cm, and tighten the screws to fix it; according to the size of 4cm, it can be seen that four 4cm×4cm× For samples with a 4cm simulated structural surface, 4 jackets can be placed on the B-type and C-type outer plates respectively, and one jacket can be placed on the outer plates with the indication scales of 4cm, 8.5cm, 13cm, and 17.5cm respectively. Tighten the screws on it to fix it with the outer plate; then select 3 curved boards with a width of 5cm and insert them into the slots at 4cm, 8.5cm, and 13cm respectively, and choose a flat board with a width of 5cm to insert 17cm In the slot at the place, the complete assembly of the mold un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com