Engineering machinery axle housing vertical bending fatigue test system

A technology of bending fatigue and test system, applied in the field of fatigue test system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation scheme is described below in conjunction with the drawings.

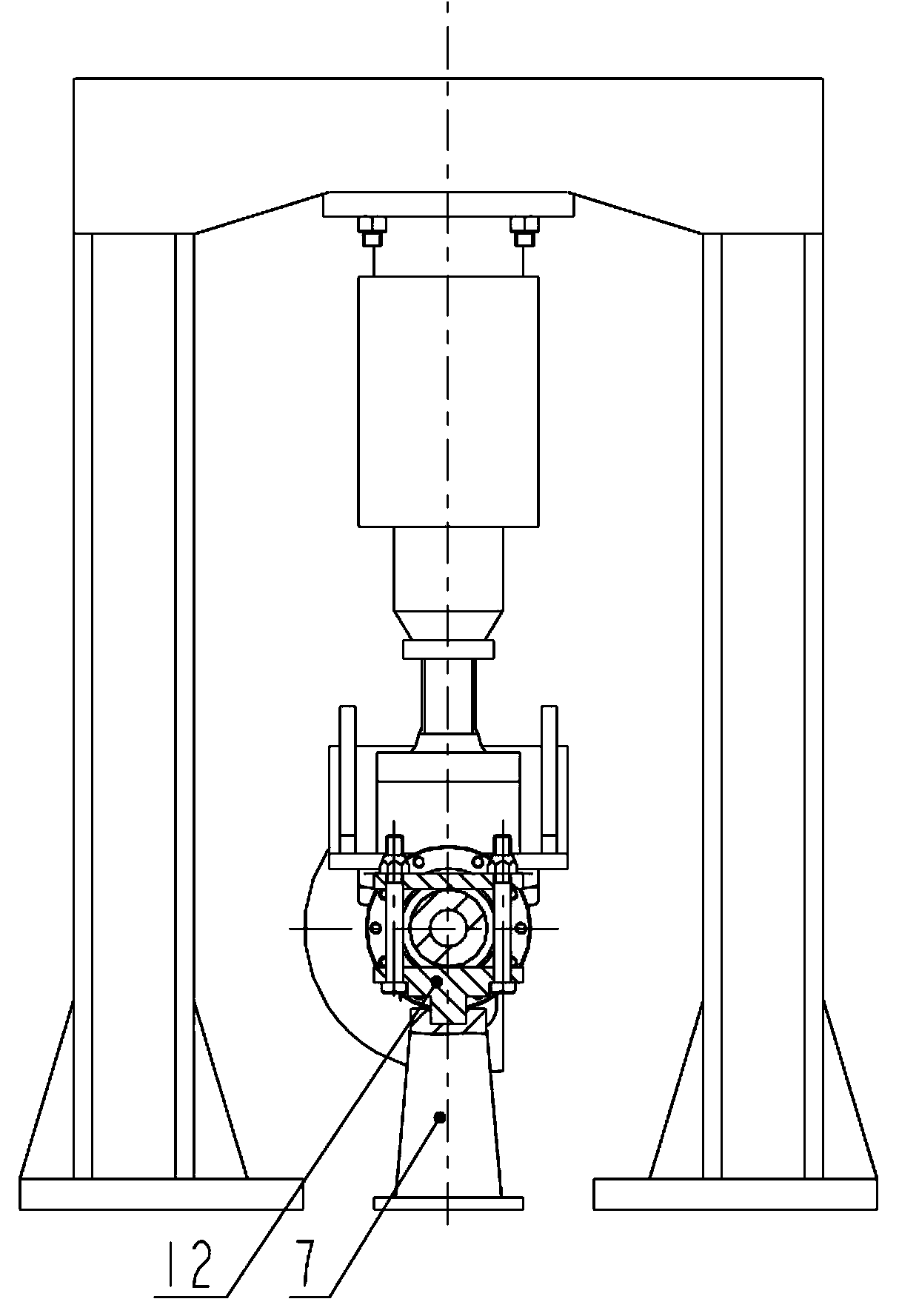

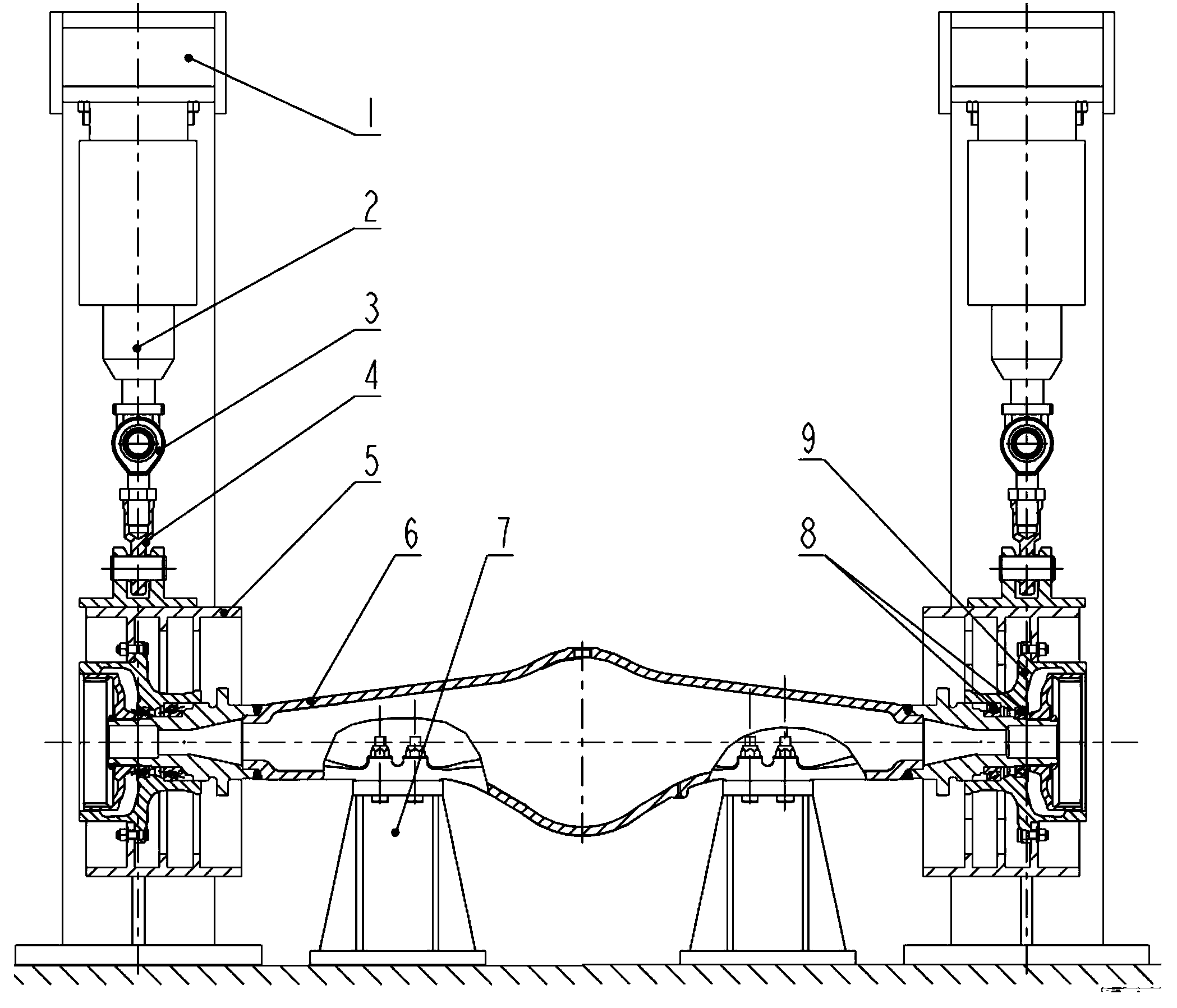

[0027] Such as image 3 Figure 4 As shown, the vertical bending fatigue test system of the engineering machinery axle housing includes the test device and the axle housing sample used for testing. The test device includes two supports 7 arranged side by side. The supports 7 are fixedly installed on the bottom surface or the test platform. The two gantry 1 are arranged on both sides of the two supports 7, and the gantry 1 is also fixedly installed on the bottom or On the test platform, a hydraulic actuator 2 is set on each gantry 1. The axle housing sample 6 is placed on the support 7 horizontally and inversely, wherein the two spring plates on the axle housing sample 6 face down and are correspondingly placed on the two supports 7 and fixedly connected with the support 7. A wheel hub 9 is installed at both ends of the axle housing sample 6 through wheel rim rolling bearings 8. A sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com