High-precision electronic belt scale

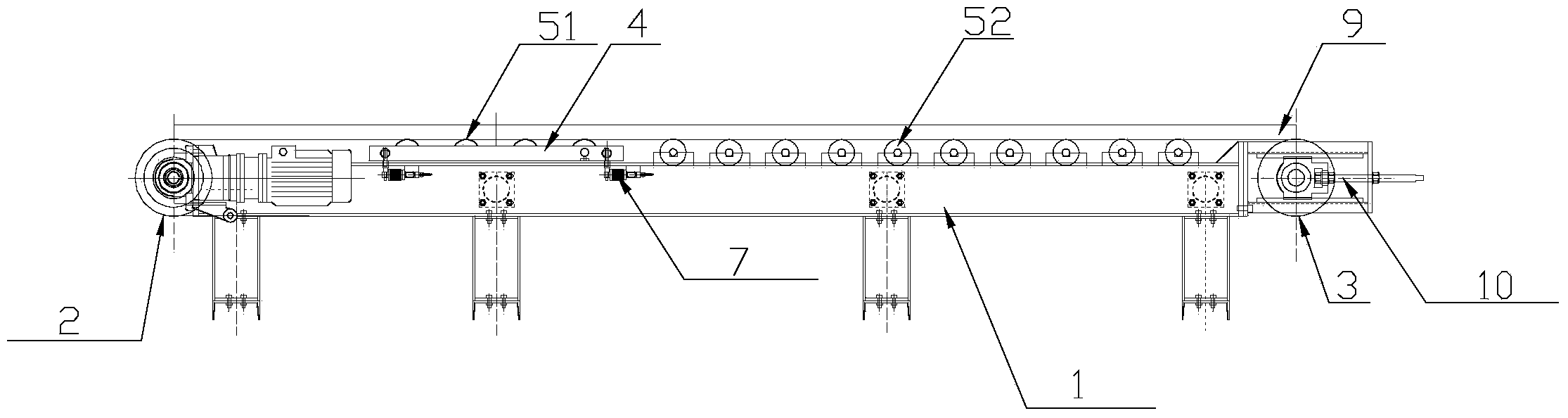

An electronic belt scale, high-precision technology, applied in the direction of measuring devices, instruments, weighing, etc., can solve the problem of low measurement accuracy of ordinary quantitative feeders, achieve the effect of convenient installation and adjustment, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the two ends of the two outer flat irons 42 are respectively provided with screw mandrels 6 on the measuring scale frame 4, that is, the number of load cells 7 is four, and four measuring scale frames are provided between the measuring scale frame 4. The idler rollers 51, the distance between each metering idler roller 51 is 200mm. This situation is to realize the purpose of the invention of the present invention, and the number of load cells and weighing rollers is the least, which can meet the requirements of general users. The distance between the metering rollers is 200mm, which is the most suitable value obtained after many experiments. At this time, the length of the entire quantitative feeder is moderate, and the operation is the most stable.

Embodiment 2

[0037] Embodiment two, the two ends of two outer flat irons 42 are respectively provided with screw mandrels 6 on the described measuring scale frame 4, and the middle parts of two outer flat irons 42 are respectively provided with screw mandrels 6, that is, the load cell 7. The number is six, and four measuring idler rollers 51 are provided between the measuring scale frames. This situation is to achieve higher measurement accuracy while realizing the purpose of the present invention, or to ensure that the entire quantitative feeder is smoothly continue to operate.

Embodiment 3

[0038] Embodiment three, the two ends of the two outer flat irons 42 are respectively provided with screw mandrels 6 on the measuring scale frame 4, that is, the number of load cells 7 is four, and six measuring scale frames are provided between the measuring scale frame 4. Roller 51. This situation is the situation of lengthening the metering interval and metering more materials while realizing the purpose of the invention of the present invention.

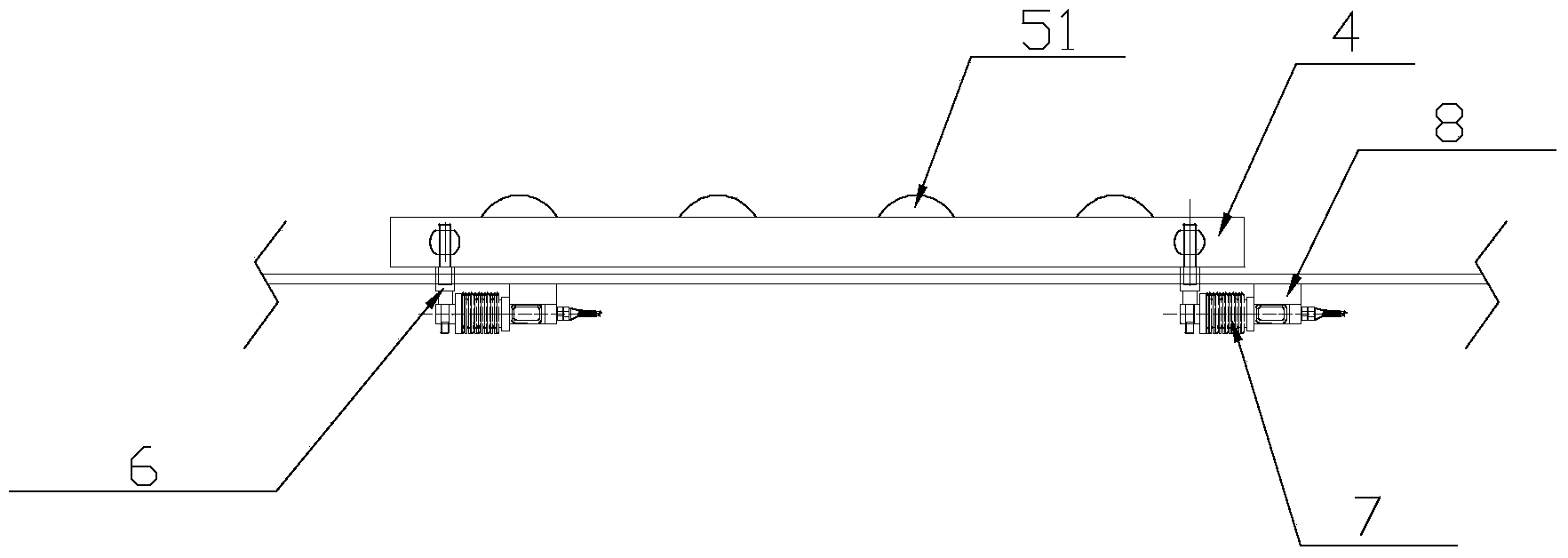

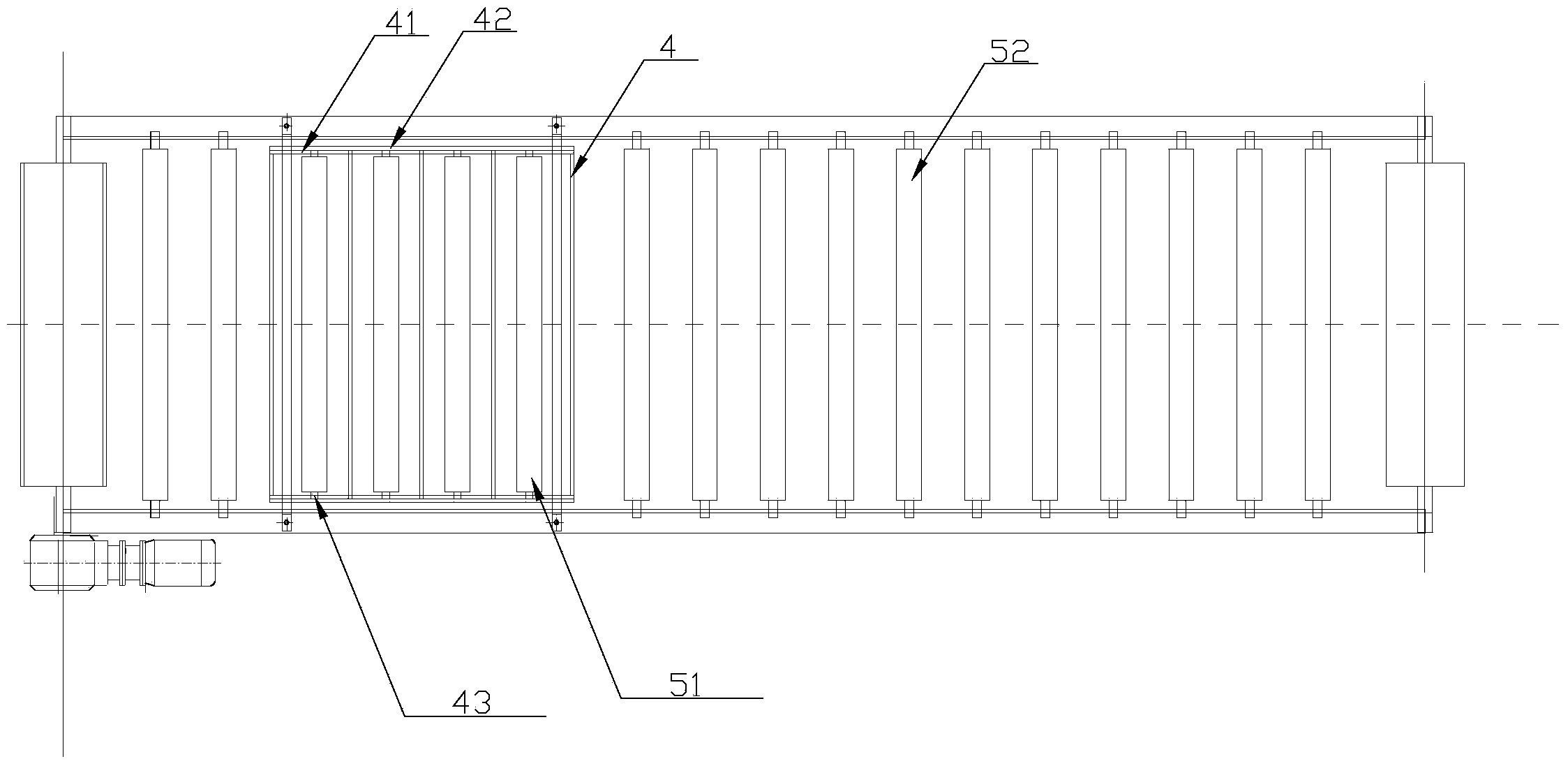

[0039] to combine image 3 and Figure 4 , it can be seen that the measuring scale frame 4 is welded by six flat irons, wherein the two sides perpendicular to the measuring roller 51 are welded by two inner and outer flat irons. The flat irons are not only light in material, but also because of the The thickness is small, the entire measuring scale frame takes up less space, and it is not easy to accumulate dust. In the present invention, it is found through experiments that the thickness of the flat iron is 8-10 mm, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com