A multi-effect regenerative heat source tower heat pump system and method

A heat source tower heat pump, heat source tower technology, applied in heating mode, air conditioning system, machine operation mode, etc., can solve the problems of affecting condensation heat transfer effect, sludge and solute reverse osmosis, single effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

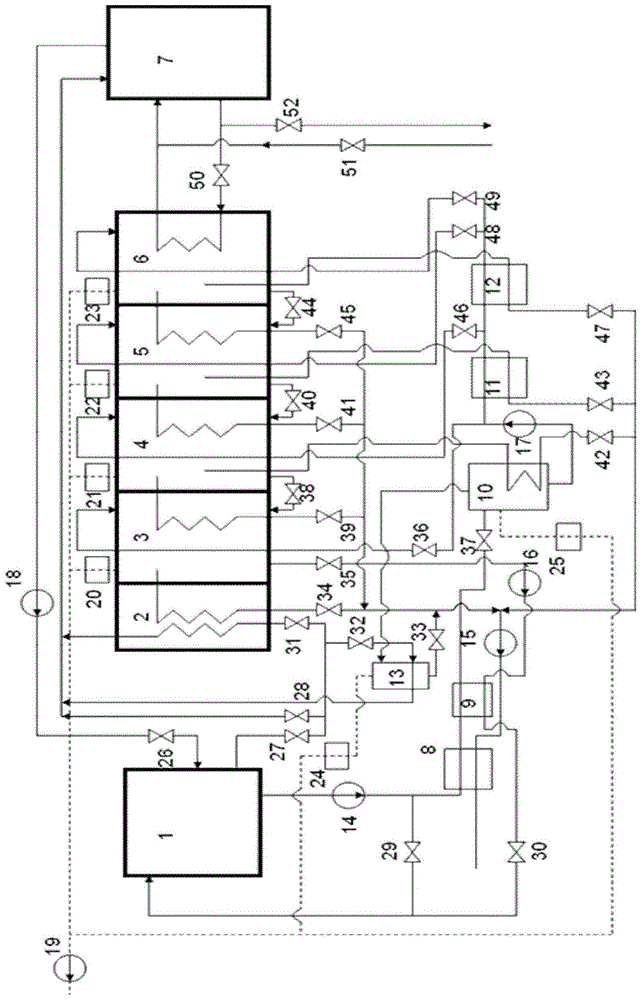

[0021] Embodiment 1, figure 1 A multi-effect regenerative heat source tower heat pump system and method are given, including a working subsystem and a regenerative subsystem.

[0022] The working subsystem includes closed heat source tower 1 (built-in circulating solution), heat source tower circulating pump 14, bypass regulating valve 29, heat pump unit 7, organic solution circulating pump 18, inlet regulating valve 26, outlet regulating valve 27, condenser Bypass regulating valve 28 , return water regulating valve 51 and water supply regulating valve 52 . The regenerative subsystem includes condenser 2, fourth effect heat exchange chamber 3, third effect heat exchange chamber 4, second effect heat exchange chamber 5, first effect heat exchange chamber 6, condensation water heat exchanger 8, solution heat exchange Device 9, degassing chamber 10, first heat exchanger 11, second heat exchanger 12, condensation degassing chamber 13, condensed water pump 15, first solution boost...

Embodiment 1

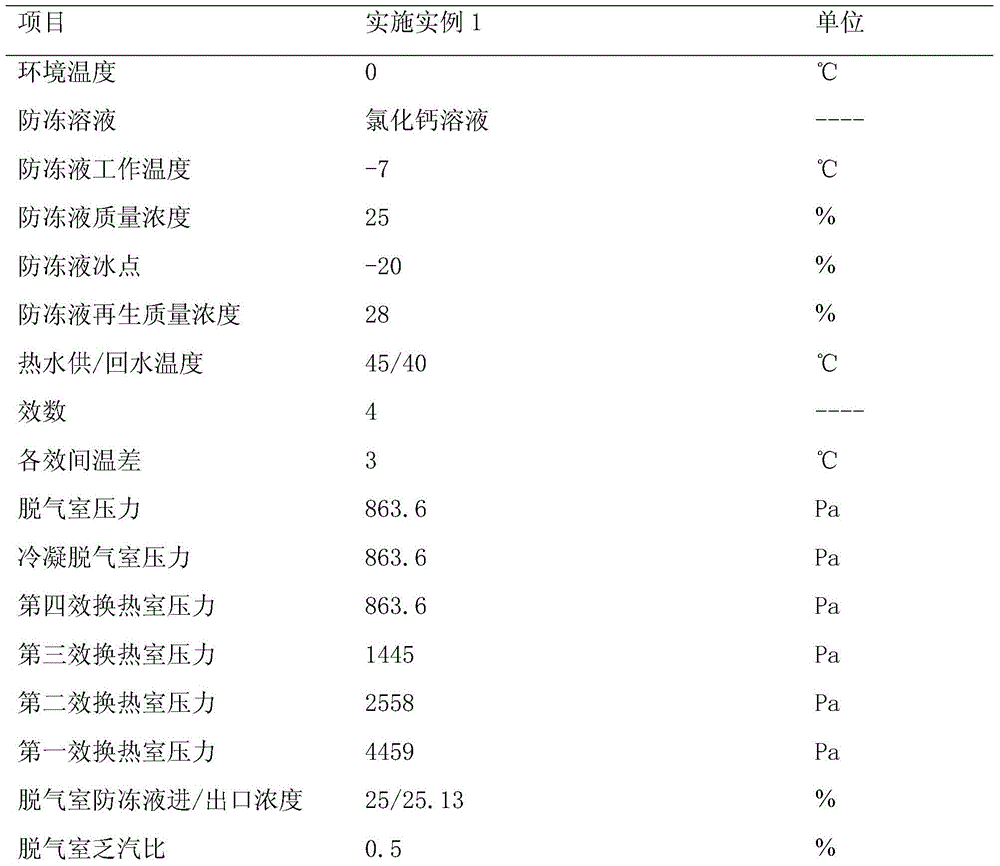

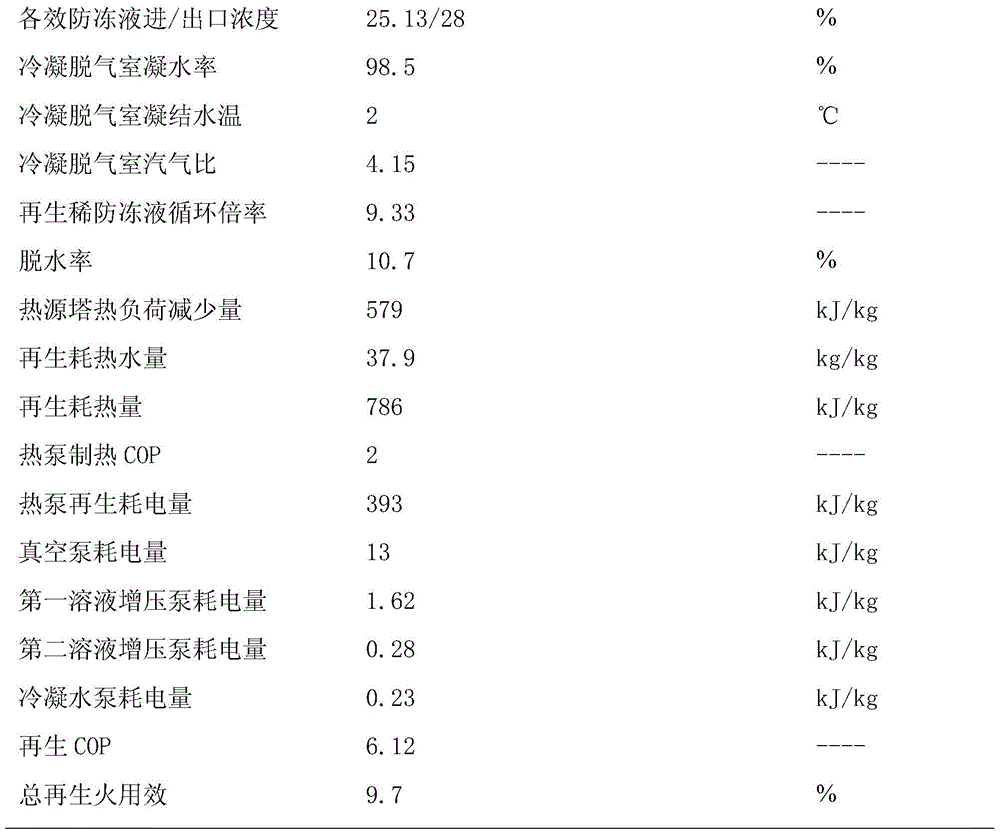

[0059] The calculation parameters of implementation example 1 are shown in Table 1 (for 1 kg of water vapor absorbed by the heat source tower heat pump system from the air), the system is in the regeneration mode under winter working conditions, and the design conditions are: ambient temperature 0 ° C, calcium chloride is used as the antifreeze solution solution, the mass concentration is 20%, the freezing point of the antifreeze solution is -20°C, the regeneration mass concentration of the antifreeze solution is 28%, the temperature of the hot water inlet and outlet is 45 / 40°C, 4-effect regeneration is adopted, and the heat transfer temperature difference between the effects is 3°C , the minimum pressure of the system is 863.6pa (absolute pressure), the maximum pressure is the pressure of the first effect heat exchange chamber 4459pa, the exhausted steam in the degassing chamber accounts for 0.5% of the liquid intake, the condensing water temperature in the condensing and degas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com