Composite combustion energy-saving furnace used for combusting patch fuels

A block fuel, energy-saving furnace technology, used in household furnaces/stoves, solid heating fuels, lighting and heating equipment, etc., can solve the problems of air pollution, fuel waste, and high room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

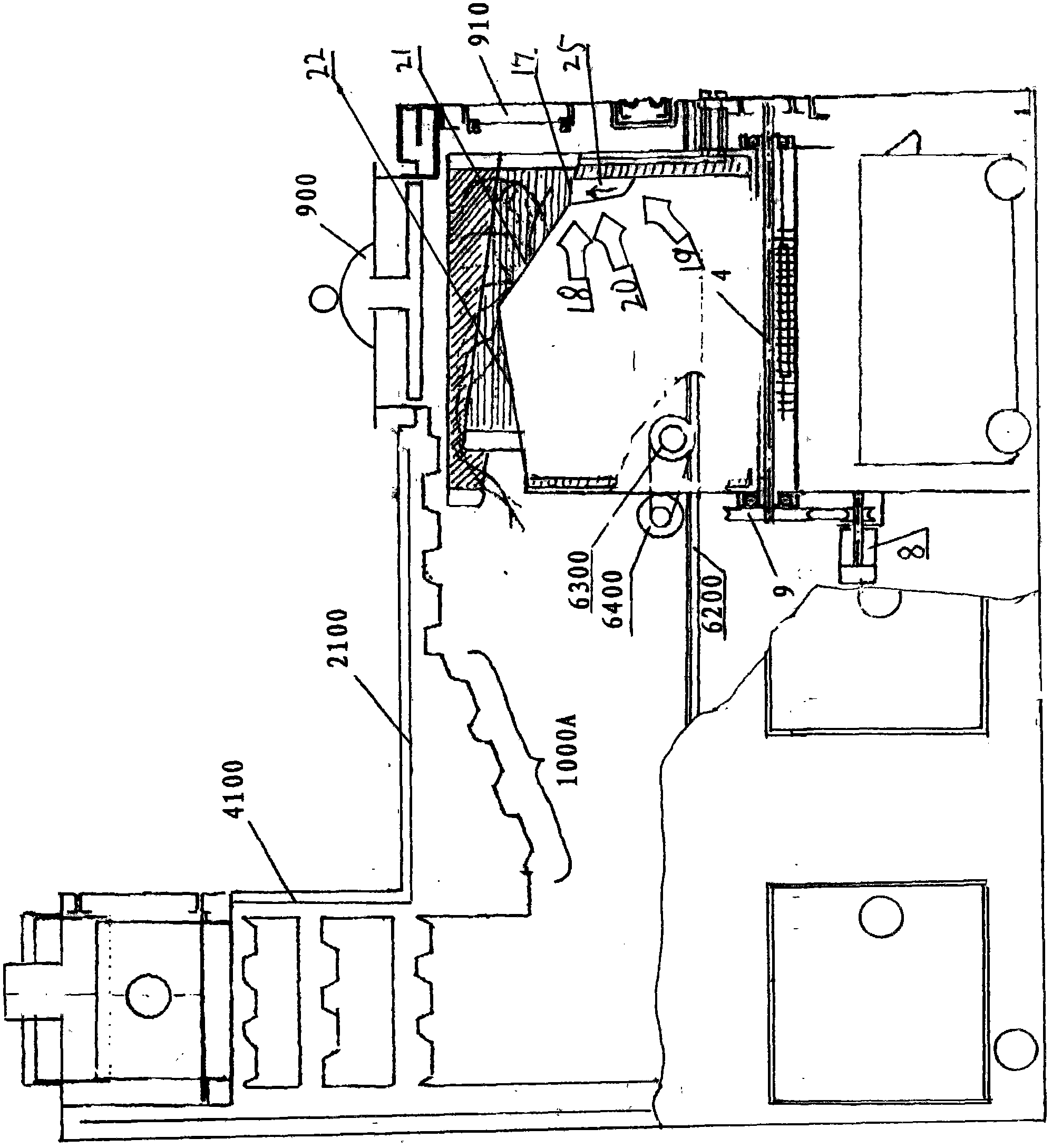

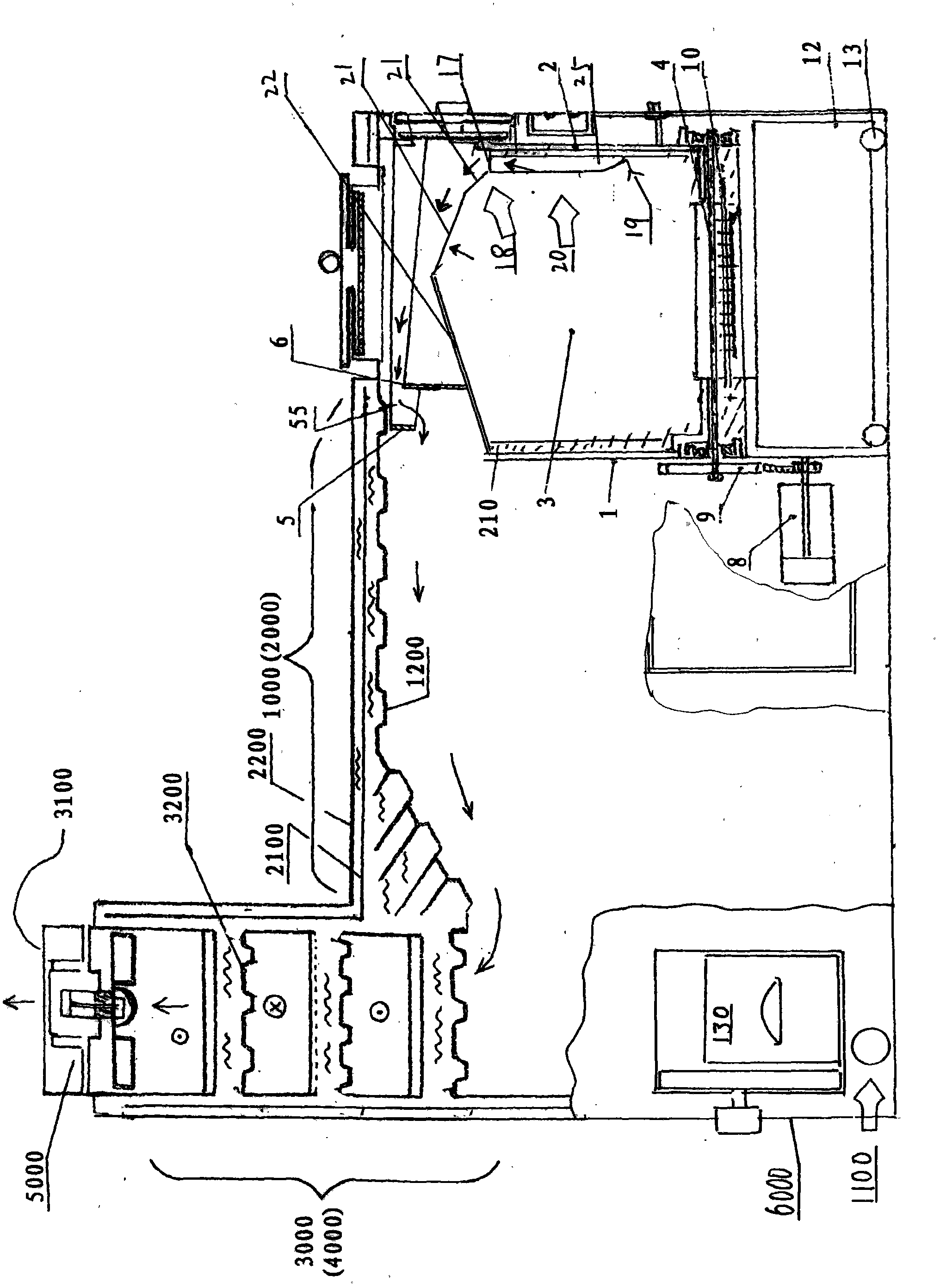

[0042] The preferred implementation of the directional deflector of the present invention will be described in detail below with reference to the accompanying drawings.

[0043] Such as Figure 1-Figure 8 As shown, a compound combustion energy-saving furnace for burning block fuels includes: a housing 1, a furnace 3 is arranged in the center of the housing 1, and a plurality of fuel support strips for supporting fuel are arranged below the furnace 3 4. The fuel can be burned for the first time in the furnace 3; it is characterized in that:

[0044] The top of the combustion chamber 3 is set as a semi-closed fire outlet 14, and the upper end surface of the semi-closed fire outlet 14 is set as a combustion surface 21 and a smoke exhaust surface 22;

[0045]The smoke exhaust surface 22 of the combustion chamber 3 is inclined downward at the front end of the smoke exhaust direction, the combustion surface 21 of the combustion chamber 3 is inclined downward in the opposite directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com