A fixed connector for solid-wall pipe layout

A solid-wall pipe and connector technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, machinery and equipment, etc. The effect of labor intensity, easy operation, and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

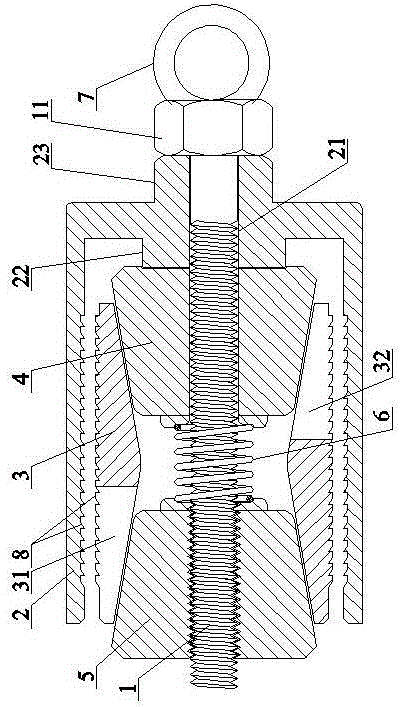

[0022] Such as figure 1 , figure 2 and image 3 The solid-walled pipe arrangement fixed connector shown includes a screw rod 1 and a barrel-shaped outer cylinder 2. A circular through hole 21 is provided at the bottom of the outer cylinder 2. The threaded end of the left end of the screw rod 1 extends through the through hole 21. into the inside of the outer cylinder 2; the inner and outer ends of the through hole 21 of the outer cylinder 2 are respectively provided with an inner circular boss 22 and an outer regular hexagonal boss 23, which are used to improve the structural strength of the outer barrel 2 and prolong the service life. Ridged boss 23 is convenient for adjustable wrench operation. The non-threaded end of the screw rod 1 is provided with a regular hexagonal prism section 11 and a pull ring 7, the regular hexagonal prism section 11 is convenient for operation with an adjustable wrench, and the pull ring 7 is convenient for connecting traction equipment to pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com