fluid transmission

A technology for fluid transmission and transmission components, applied in fluid transmission, transmission, vibration suppression adjustment, etc., can solve the problems of increased number of components, increased weight, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] (Structure of torque converter)

[0020] The structure of the torque converter 10 according to the embodiment of the fluid power transmission device of the present invention will be described.

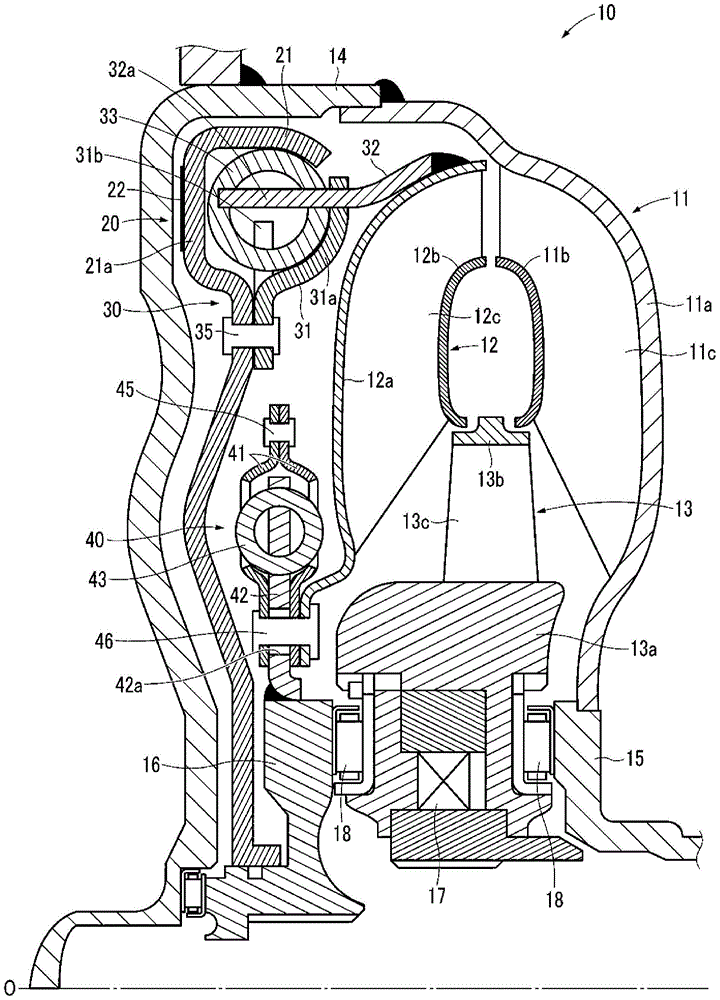

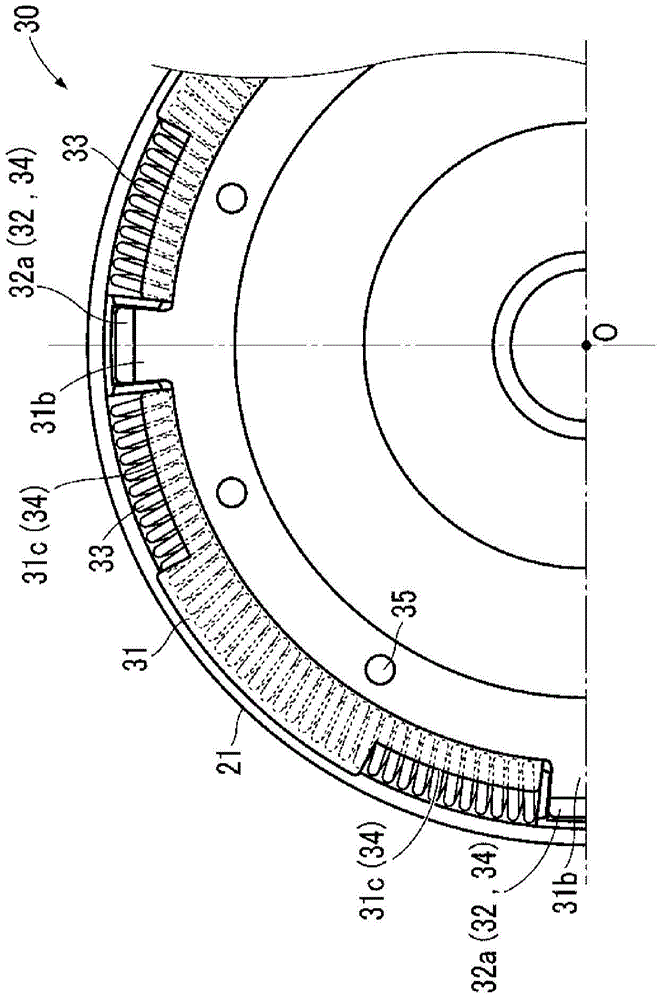

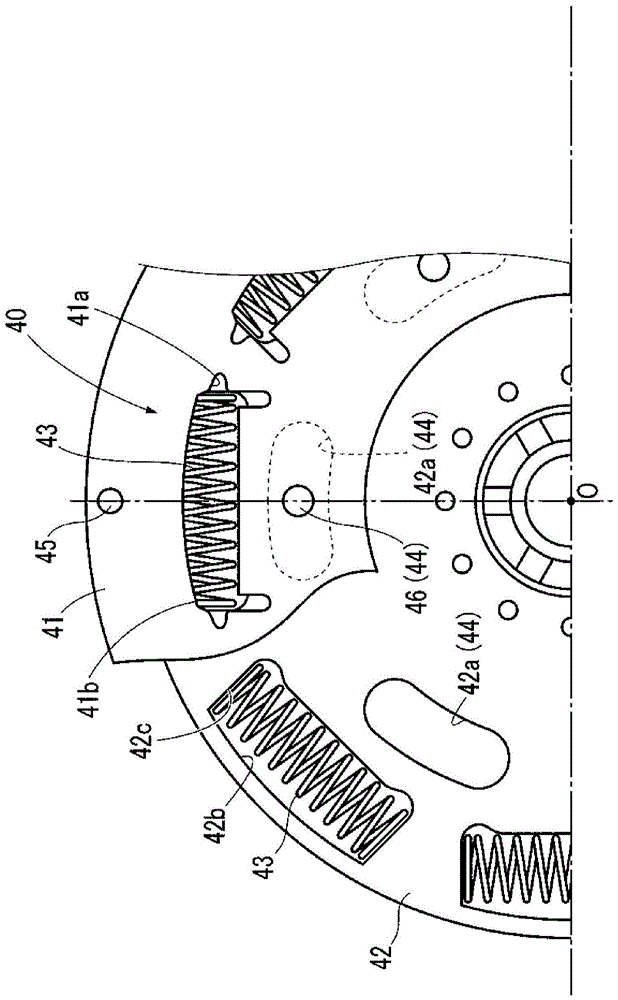

[0021] Such as figure 1 As shown, the torque converter 10 has a shroud 14 and three types of impellers, namely, a pump impeller 11 , a turbine 12 and a stator 13 . An annular passage for circulating hydraulic oil is formed by the pump impeller 11 , the turbine wheel 12 and the stator 13 .

[0022] The torque converter 10 further includes a lock-up clutch 20 and two damper mechanisms 30 and 40 arranged between the turbine wheel 12 and the cover 14 .

[0023] The pump impeller 11 is fixed to the cover 14 by welding. The cover 14 is connected to an unshown drive shaft (engine crankshaft) to which a drive force from a drive source such as an unshown engine is transmitted, and rotates around a center axis O as the drive shaft rotates.

[0024] The turbine 12 is disposed opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com