Teeth-difference rigidity scaling adjusting mechanism and method for spinning machine

A technology for adjusting mechanism and tooth difference, applied in the field of tooth difference rigid indexing adjustment mechanism for textile machines

Inactive Publication Date: 2014-12-24

QINGDAO KANGWEILONG COMMODITY COMPANY

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During use, when adjusting the gear transmission device, if a tooth difference needs to be rotated clockwise or counterclockwise between the upper part and the middle part, then the lower part and the middle part can be adjusted as needed. Parts rotate one tooth difference or multiple tooth differences in the same order, thus solving the problem of changing or adjusting the zeroing angle between the upper and lower layers or maintaining synchronization

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

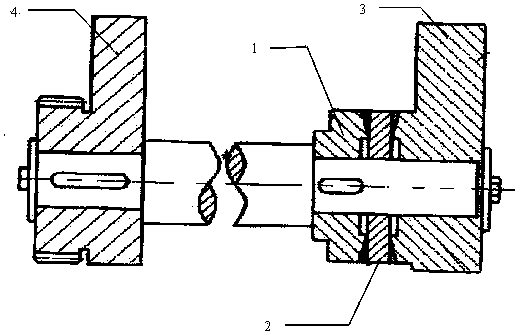

The invention provides a teeth-difference rigidity scaling adjusting mechanism for a spinning machine. The teeth-difference rigidity scaling adjusting mechanism comprises an upper part, an intermediate part and a lower part which are connected by a mouse tooth clutch, the number of teeth between the upper part and the intermediate part is Z, and teeth difference between the upper part and the lower part is 1, 2, 3 or N which is an integer larger than or equal to 1. When a gear transmission device is adjusted and if the upper part and the intermediate part rotate clockwise or anticlockwise by one teeth difference, the lower part and the intermediate part rotate by one or more teeth differences according to the same sequence. The teeth-difference rigidity scaling adjusting mechanism can be used on a same shaft and transmit to multiple planes, thereby being capable of accurately synchronizing or distributing according to a certain fixed angle. Accordingly, error in machining or mounting is eliminated.

Description

technical field [0001] The invention belongs to the technical field of textile machinery, and in particular relates to a tooth difference rigid index adjustment mechanism and method for textile machinery. [0002] Background technique [0003] Gear is the basic part of mechanical equipment and the most widely used form of transmission. It occupies an important position in the field of production and manufacturing. It has constant instantaneous transmission ratio, stable operation, accurate and reliable transmission, high transmission efficiency, applicable power and speed range In the structure of traditional textile machinery, the problem of precise synchronization between two or more related gear components is a technical difficulty. Due to the structure of the components, the tooth direction or the radial error of the ring gear is often the result of the component running or Maintenance is more difficult, and the radial runout error and tooth direction error of the ring ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16D23/02

Inventor 解云龙

Owner QINGDAO KANGWEILONG COMMODITY COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com