Flat band bonding machine

A bonding machine and flat belt technology, applied in mechanical equipment, connecting components, etc., can solve problems such as low production efficiency, deviation, and large transmission energy loss, so as to make up for the vacancy of production equipment and strengthen the bonding fastness , the effect of meeting the needs of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

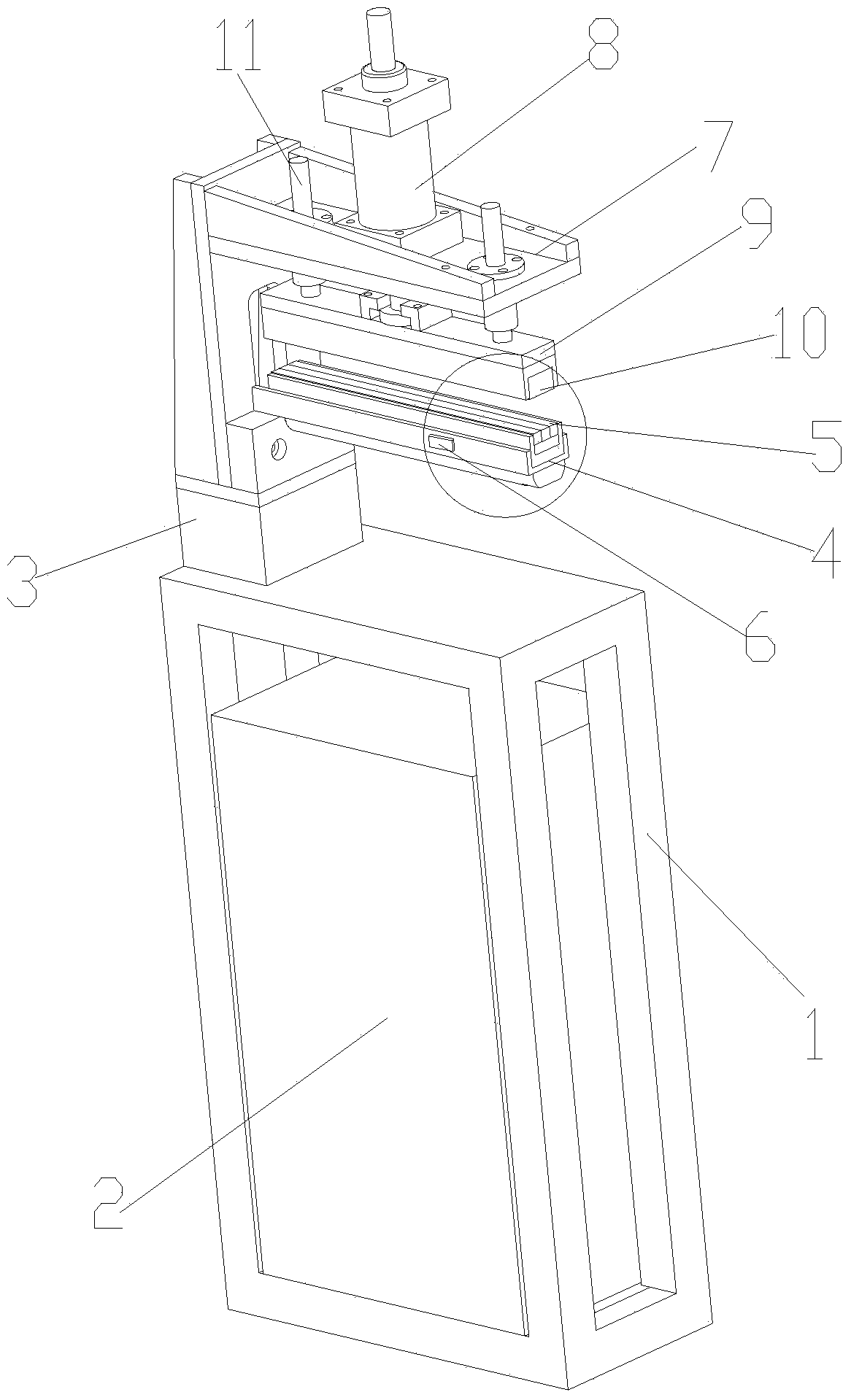

[0017] as attached Figure 1-5 The shown flat belt bonding machine of the present invention includes a frame 1, a control system 2, a support frame 3, a lower bezel 4, a heating plate 5, a temperature sensor 6, a fixing plate 7, a cylinder 8, an upper bead 9 and iron sheet 10; the frame 1 is provided with a control system 2; one side of the top of the frame 1 is provided with a support frame 3; the middle part of the support frame 3 has a groove; The lower bezel 4 is fixed; the lower bead 4 is provided with a plurality of heating plates 5; one side of the lower bead 4 is also provided with a temperature sensor 6; the support frame 3 is provided with a fixed plate 7; the fixed plate 7 is provided with a cylinder 8; the telescopic rod of the cylinder 8 is provided with an upper bead 9; the upper bead 9 is located between the fixed plate 7 and the lower bead 4; an iron sheet 10 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com