A device for controlling the load and deformation of wind turbine blades

A wind turbine blade and load technology, applied in wind turbines, wind turbines, wind turbine control and other directions that are consistent with the wind direction, can solve the problems of reduced braking efficiency, slow dynamic response, increased energy consumption, etc. Balanced, low power consumption, effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

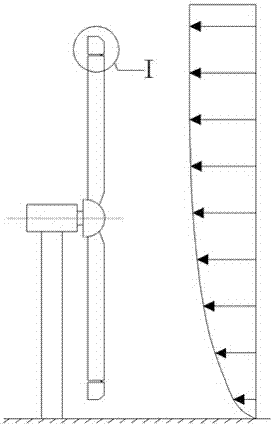

[0031] A device for controlling the load and deformation of wind turbine blades proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Such as figure 1 , 2 As shown in and 3, a device for controlling the load and deformation of wind turbine blades includes a damping regulator 2, a rotating shaft fixing device 3, a rotating shaft 4, a freely rotating blade 5, a rudder surface 7, a steering gear 6, a transmission rod 8, and a hinge 9. The radial length of the freely rotating blade 5 is 5% to 50% of the radial length of the wind turbine blade 1, and the radial length of the freely rotating blade 5 is determined according to factors such as the use environment and the length of the wind turbine blade 1. Its plane shape is straight form or sharpened form, and the cross-sectional shape of freely rotating blade 5 matches the cross-sectional shape of wind turbine blade 1 top, and the section chord length of freely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com