A split-leg method for running a herringbone sealing device for branch wells

A sealing device and branch well technology, which is applied to earth-moving drilling, wellbore/well components, etc., can solve the problems of jamming, inconsistent speed of split legs, etc., to prevent instability, deformation and crowding, easy operation, and reliable running. effect in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

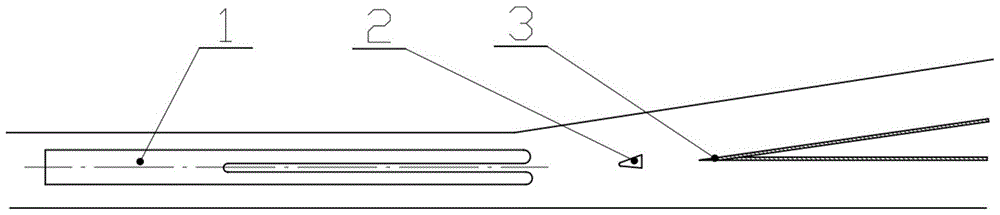

[0008] Such as figure 1 As shown, a branch well uses a herringbone-shaped sealing device to run the split-leg method. The method steps are as follows: After the two branch wellbores of the branch well are drilled, the lower edge 3 of the branch well window is formed at the branch well window, and the fixed-point split-leg mechanism 2. The upper part is cone-shaped or wedge-shaped, and the upper part of the cone-shaped or wedge-shaped has smooth chamfers. Install the fixed-point leg splitting mechanism 2 on the upper part of the lower edge of the branch well window 3 to ensure that the herringbone sealing device 1 is connected to the lower edge of the branch well window. 3. The front two legs at the apex of the tip are reliably separated to avoid damage to the herringbone sealing device 1; the herringbone sealing device 1 is made of high plastic material and has good deformation ability without damage; the fixed-point leg separation mechanism 2 is located in the herringbone seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com