Replacement device and method for filler of empty hole part of bored pile

A technology for bored piles and fillers, which is applied to sheet pile walls, buildings, infrastructure engineering, etc. And safety, does not affect the construction period, the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

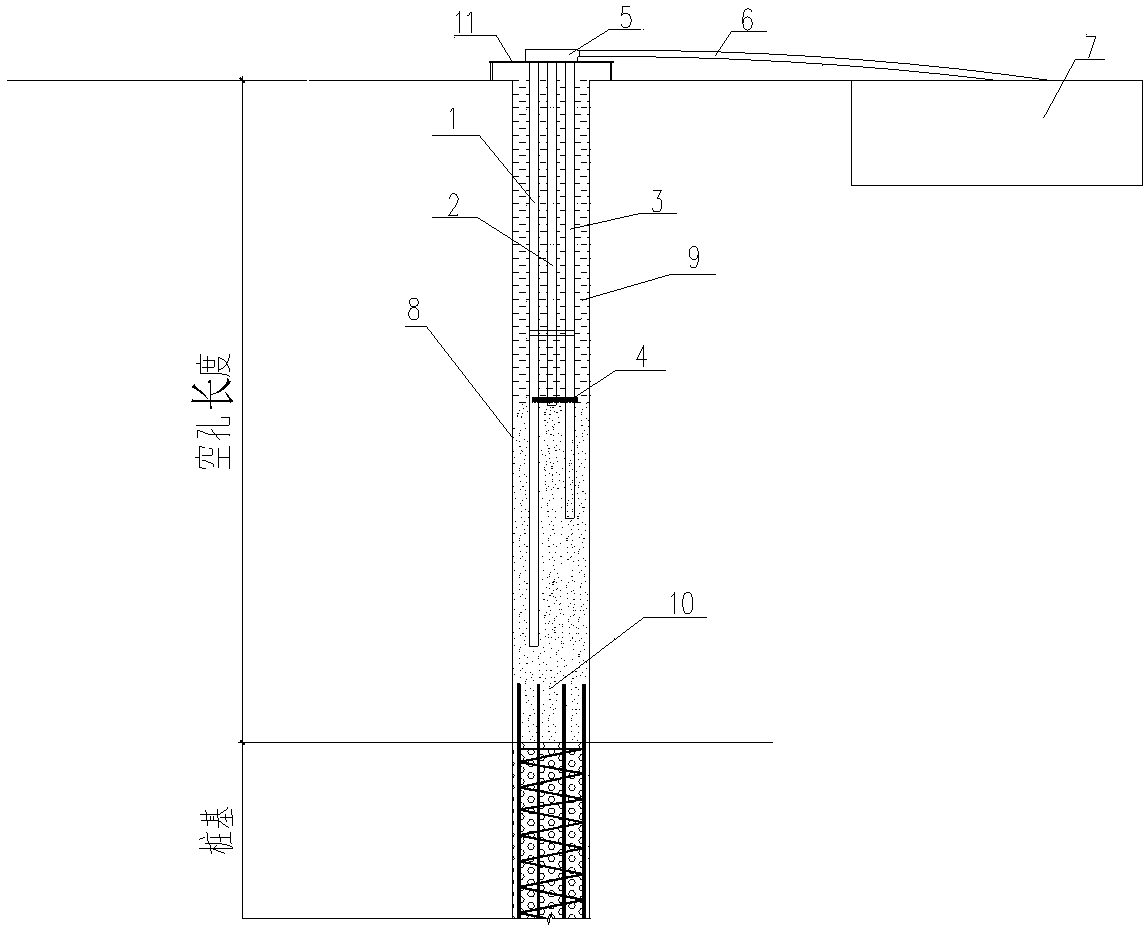

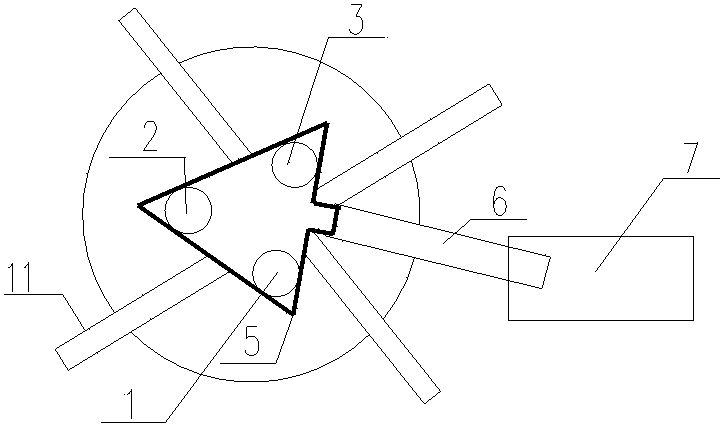

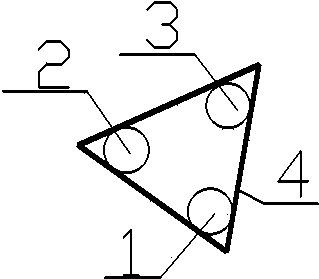

[0029] Such as Figure 1 to Figure 3 As shown, it is a diagram of the use state of a replacement device for filling the hollow part of bored piles provided by Embodiment 1 of the present invention. The empty hole 8 length among the present embodiment is 15-20 meter. The replacement device includes a first guide pipe 1 , a second guide pipe 2 , a third guide pipe 3 , a fixing frame 4 , a guide tank 5 , a hose 6 , a bracket 11 and a mud pool 7 . The bracket 11 is used to fix the ends of the three draft pipes close to the ground. In this embodiment, the bracket 11 is in the shape of a cross. The ends of the three guide pipes close to the ground communicate with the guide groove 5 . One end of the hose 6 is connected to the diversion tank 5 , and the other end of the hose 6 is connected to the mud pool 7 . The fixing bracket 4 is used to fix the bottoms of the first flow guide tube 1 , the second flow guide tube 2 and the third flow guide tube 3 . Fixture 4 is made of steel b...

Embodiment 2

[0036] This embodiment is roughly the same as Embodiment 1, except that the length of the empty holes in this embodiment is 25-30 meters, and the number of draft pipes is five.

Embodiment 3

[0038] This embodiment is roughly the same as Embodiment 1, except that the length of the empty holes in this embodiment is 20-25 meters, and the number of draft pipes is four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com