Shoe upper computer sewing machine

A sewing machine and computer technology, applied in the field of sewing processing, can solve problems such as inability to guarantee the service life, inability to hold down the workpiece, inability to complete tasks, etc., and achieve the effects of saving raw materials, improving production efficiency, and accurate stitching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

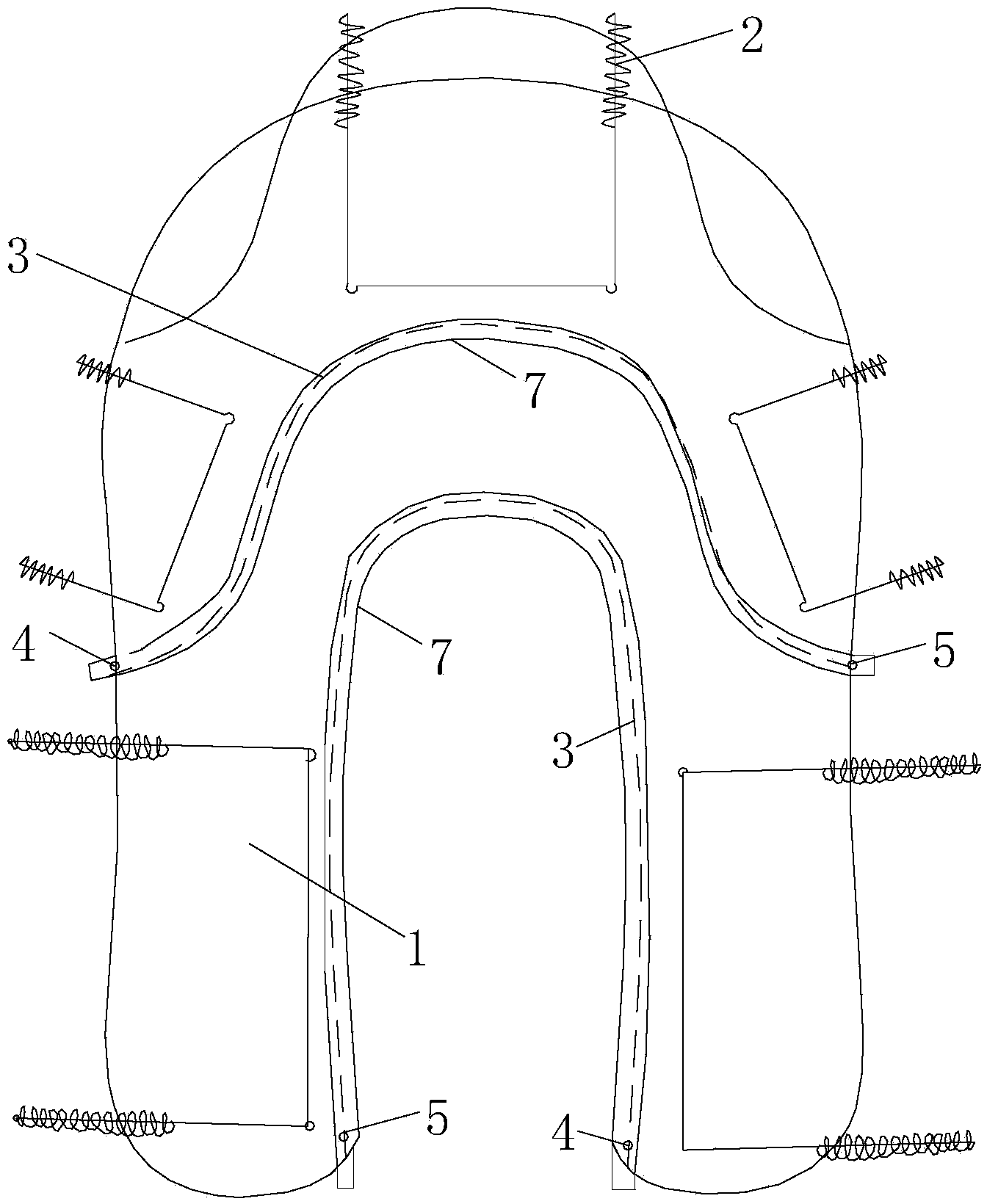

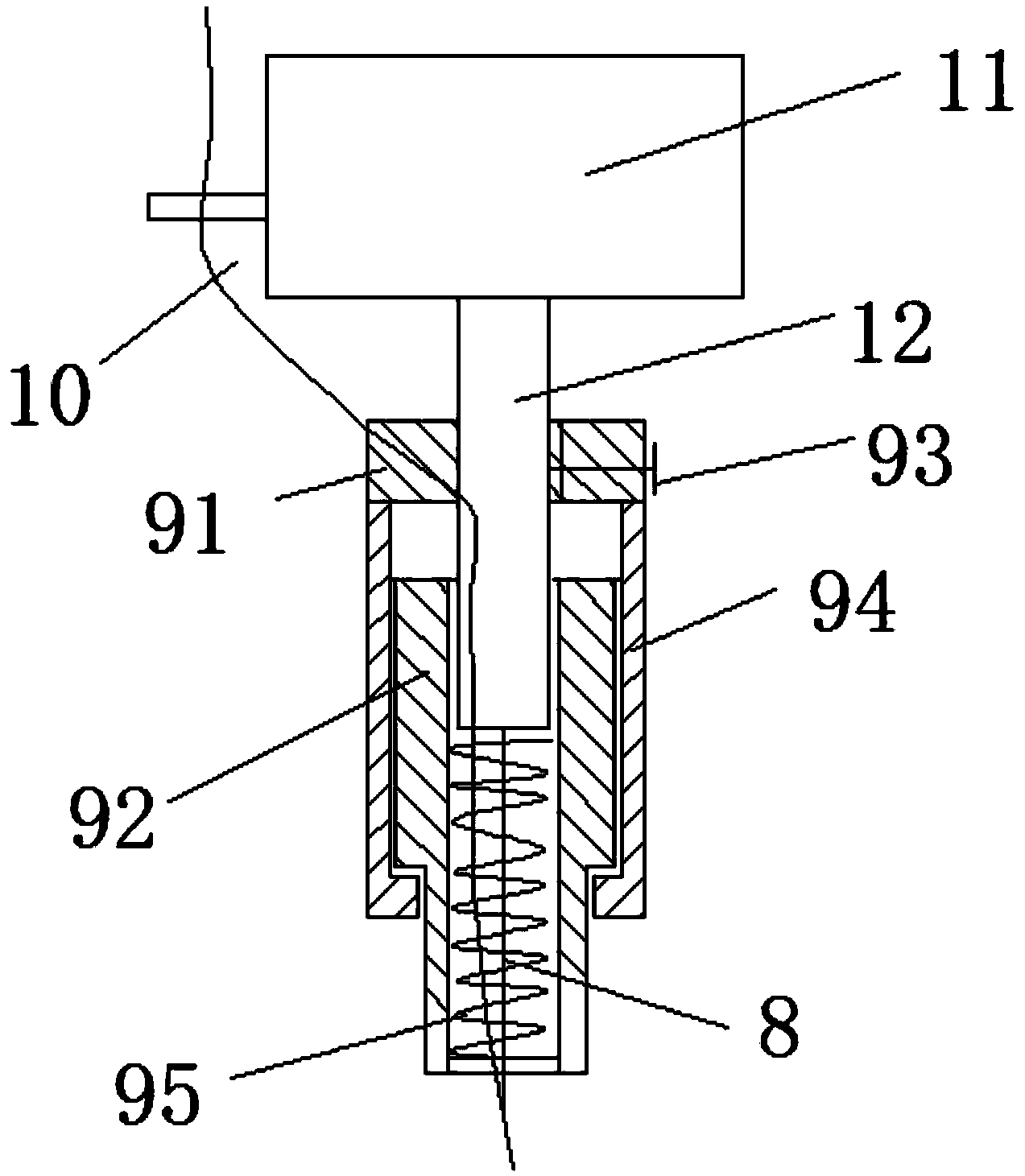

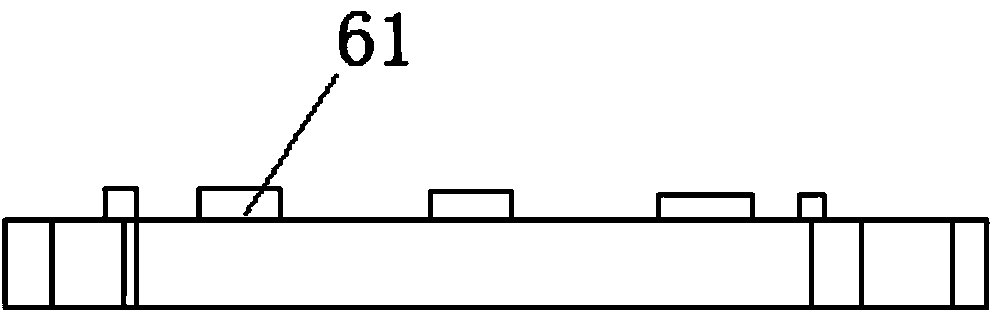

[0020] refer to Figure 1-5 , the specific embodiment adopts the following technical solutions: shoe upper computer sewing machine, including steel wire spring clamp 2, stitches 3, starting point 4, end point 5, stitch template 6, stitch channel 7, stitches are arranged under the shoe upper fabric 1 Template 6, the stitch template 6 is provided with a stitch channel 7, the stitch channel 7 is provided with a stitch 3, the beginning and the end of the stitch 3 are the starting point 4 and the end point 5 respectively, and the shoe upper fabric 1 is fixed on the On the moving platform of the sewing machine; the outer ring of the stitch channel 7 is provided with a plurality of work limiting panels 61 , and the four corners of the stitch template 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com