Brewing method of blueberry fruit wine

A blueberry fruit wine and blueberry technology, applied in the field of biochemistry, can solve problems such as complex process, unfavorable industrial production, and long time-consuming, and achieve the effect of simple process, improved wine quality, and pure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

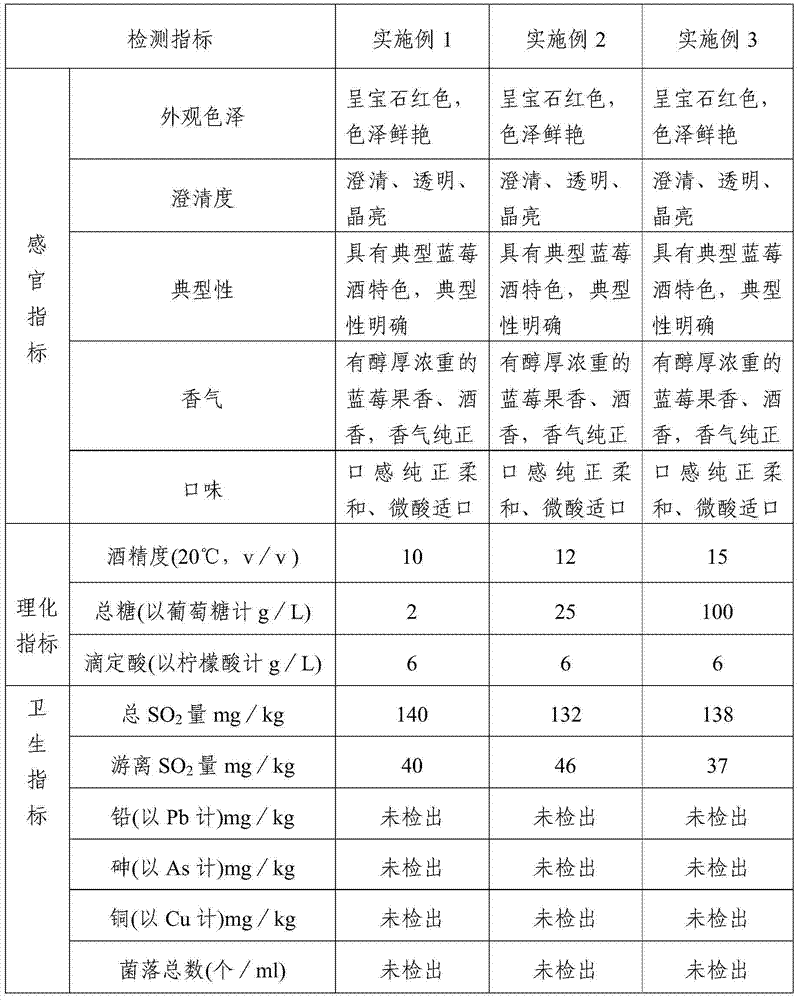

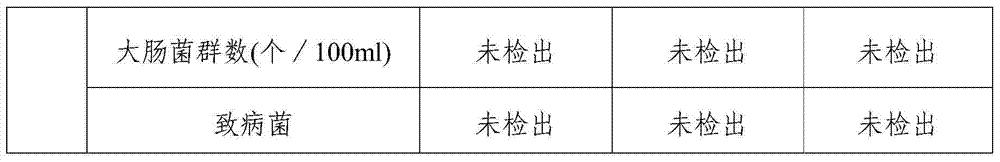

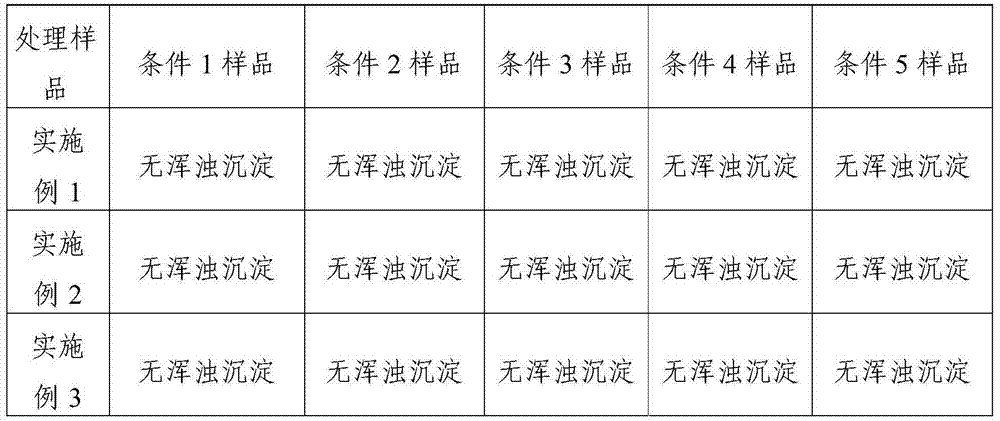

Examples

Embodiment 1

[0030] Select 2.5 kg of fresh blueberries with high maturity and intact fruit grains, remove rotten fruits, remove fruit stems and impurities, and crush and beat.

[0031] Add 12.5g of sodium citrate to adjust the pH value to 3.5, add 0.5g of potassium metabisulfite, and add 0.5g of pectinase. The enzymolysis temperature is 40°C, and the enzymolysis is carried out for 6 hours.

[0032] After enzymolysis and centrifugal filtration, put the clarified fruit juice into a fermenter, add 25g of complex bacteria, 642.5g of white sugar, 0.2g of potassium metabisulfite and 0.5g of antioxidant PVPP, stir evenly, and control the fermentation temperature at 25°C. After 48 hours of fermentation, add 55.75g of white sugar again, stir evenly, continue to ferment until the sugar content reaches below 5g / L, filter, add 0.7g of tannin to the filtrate, control the temperature at 15°C, seal and ferment for 15 days , filtered after fermentation.

[0033] Add 15g of oak chips and age at 15°C for 2...

Embodiment 2

[0035] Select 5 kg of fresh blueberries with high maturity and intact fruit grains, remove rotten fruits, remove fruit stems and impurities, and crush and beat.

[0036] Add 25g of sodium citrate to adjust the pH value to 3.0, add 1g of potassium metabisulfite, and add 1g of pectinase. The enzymolysis temperature is 60°C for 2 hours.

[0037] After enzymolysis and centrifugal filtration, put the clarified juice into a fermenter, add 50g of complex bacteria, 1260g of white sugar, 0.4g of potassium metabisulfite and 1g of antioxidant EDTA, stir evenly, and control the fermentation temperature at 28°C. After 48 hours of fermentation, add 480g of white granulated sugar again, stir evenly, continue to ferment until the sugar content reaches below 5g / L, and filter.

[0038] Add 1.4g of tannin to the filtrate, control the temperature at 10°C, seal and ferment in full barrels for 15 days, filter after fermentation, add 30g of oak chips, and age at 10°C for 18 months. After aging, add...

Embodiment 3

[0040] Select 10 kg of fresh blueberry fruits with high maturity and intact fruit grains, remove rotten fruits, remove fruit stems and impurities, crush and beat.

[0041] Add 50 g of sodium citrate to adjust the pH value to 4.0, add 2 g of potassium metabisulfite, and add 2 g of pectinase. The enzymolysis temperature is 50° C., and the enzymolysis is performed for 4 hours.

[0042] After enzymatic hydrolysis and centrifugal filtration, put the clarified fruit juice into a fermenter, add 100g of complex bacteria, 2380g of white sugar, 0.8g of potassium metabisulfite and 2g of antioxidant EDTA, stir evenly, and control the fermentation temperature at 15°C. After 48 hours of fermentation, add 2110g of white sugar again, stir evenly, continue to ferment until the sugar content reaches below 5g / L, filter, add 2.8g of tannin to the filtrate, control the temperature at 25°C, seal and ferment in full barrel for 15 days, Filtration after fermentation.

[0043] Add 30g of oak chips an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com