Swingable telescopic balance weight structure for railway crane

A technology for cranes and railways, which is applied in cranes and other directions, can solve the problems that affect the application, the structure of the telescopic arm is small, and the requirement for the inner space of the arm is large, and achieve the effect of ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

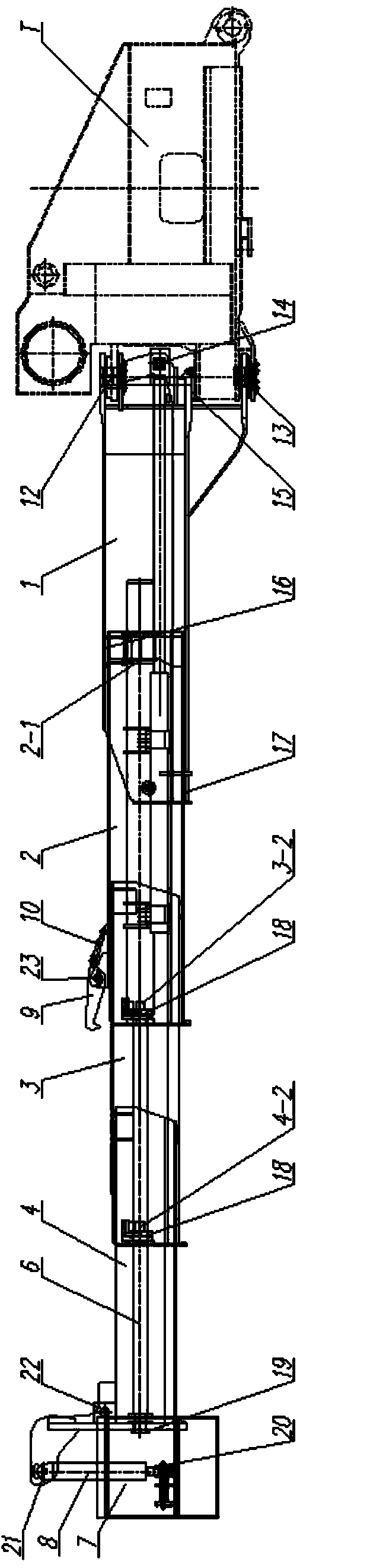

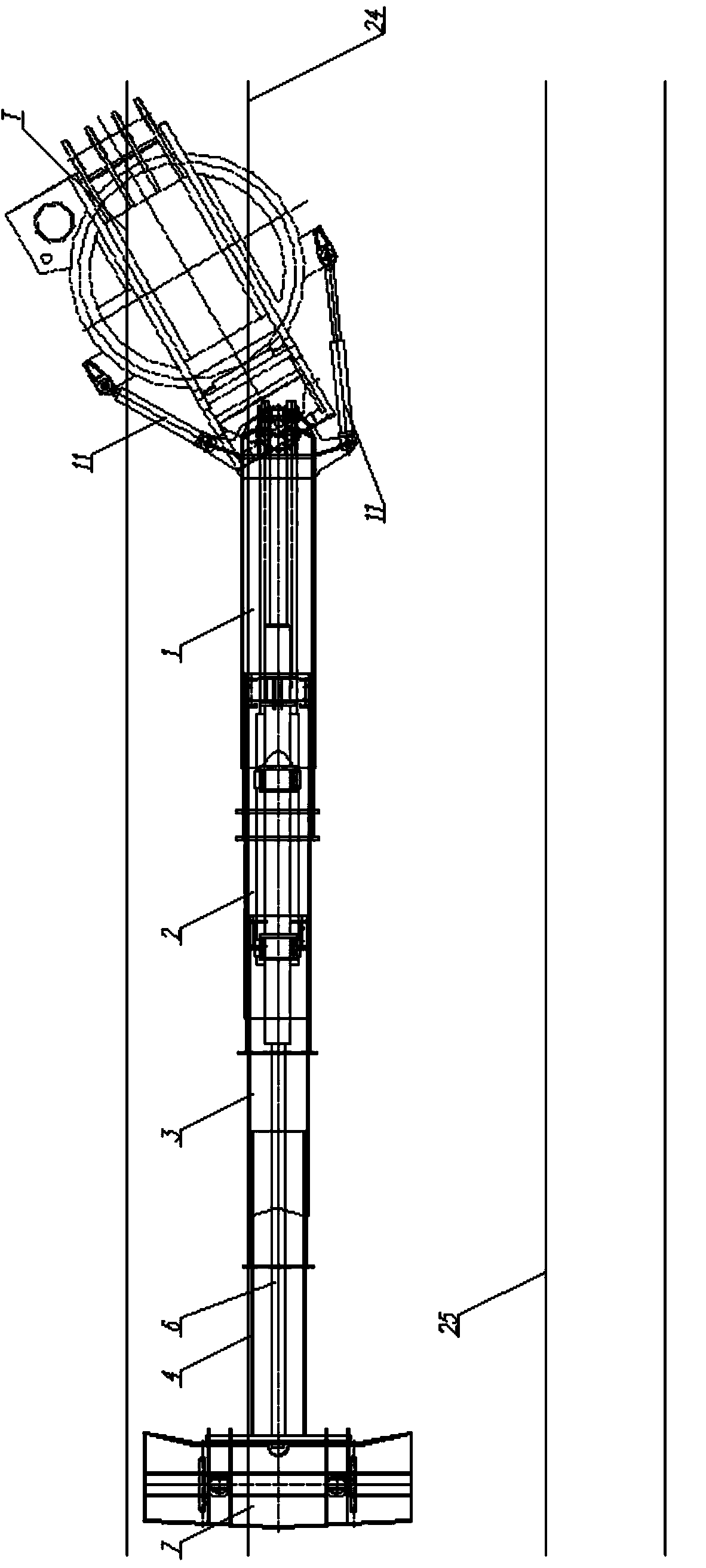

[0019] Now how the present invention is implemented in conjunction with the accompanying drawings:

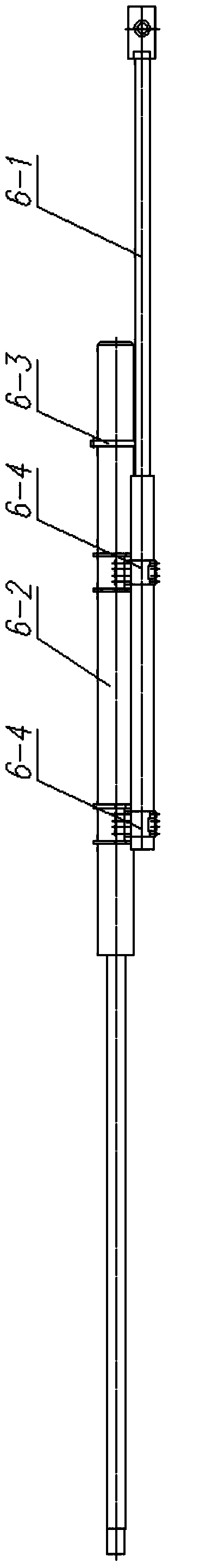

[0020] The swingable telescopic counterweight structure of the present invention includes a turntable, a telescopic arm, a counterweight body, an oil cylinder system, and a control system. The telescopic arm is composed of a basic arm, a two-section arm, a three-section arm, and a four-section arm. The joint arm 2, the three-joint arm 3 and the four-joint arm 4 are sequentially connected from outside to inside by sliding sets of sliders; the oil cylinder system is composed of a telescopic oil cylinder, a swing oil cylinder, a hanging oil cylinder and a lug oil cylinder, and the telescopic oil cylinder 6 is composed of the lower Two small oil cylinders 6-1 and an upper large oil cylinder 6-2 are composed, the lower two small oil cylinders 6-1 and the upper large oil cylinder 6-2 are connected by two flanges 6-4, and the telescopic oil cylinder 6 is connected by a flange plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com