Manufacturing method of centrifugal vapor compressor diffuser

A technology for steam compressors and manufacturing methods, which is applied in the field of centrifugal steam compressors, and can solve problems affecting the accuracy of lathes, large tool wear, poor verticality, etc., and achieve the effects of improving processing efficiency, removing local deformation, and improving verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

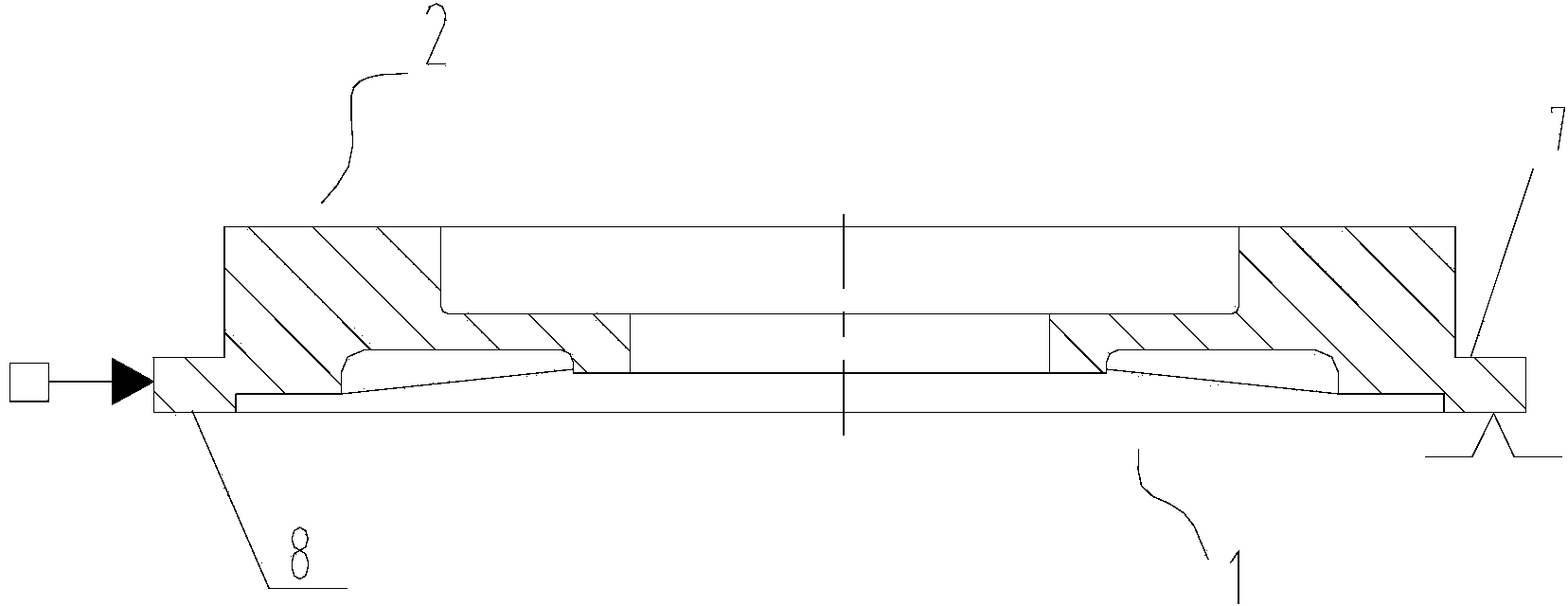

[0040] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] Such as Figure 1-7 Shown, the manufacture method of centrifugal vapor compressor diffuser of the present invention, comprises the following steps:

[0042] a. Blank heat treatment;

[0043] b. The end face, outer circle, inner hole and second step end face 9 of the large end 1 of the rough turning diffuser;

[0044] c. The end face, outer circle, inner hole and first step end face 7 of the small end 2 of the rough car diffuser;

[0045] d. Drill a positioning hole for milling on the edge of the end face of the big end 1, install the milling tool, and position through the positioning hole, rough mill the blade 3 on the small end 2;

[0046] e. The end face, outer circle, inner hole and first step end face 7 of the small end 2 of the semi-finished car diffuser;

[0047] f. The end face, outer circle, inner hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com