Multifunctional feeding manipulator for motor stator and rotor punching sheets

A technology of manipulators, stators and rotors, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve problems such as disassembly, installation, and calibration troubles, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

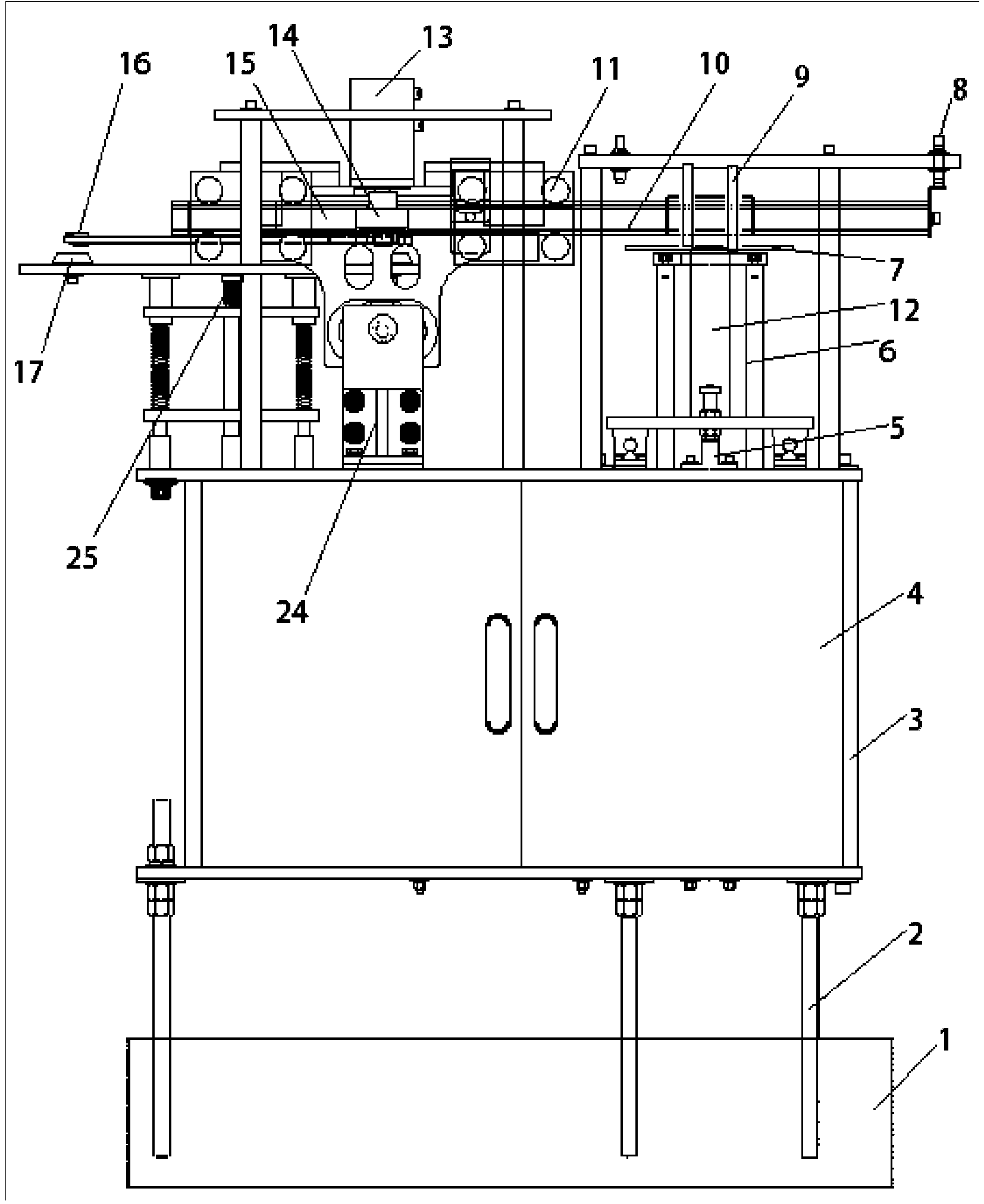

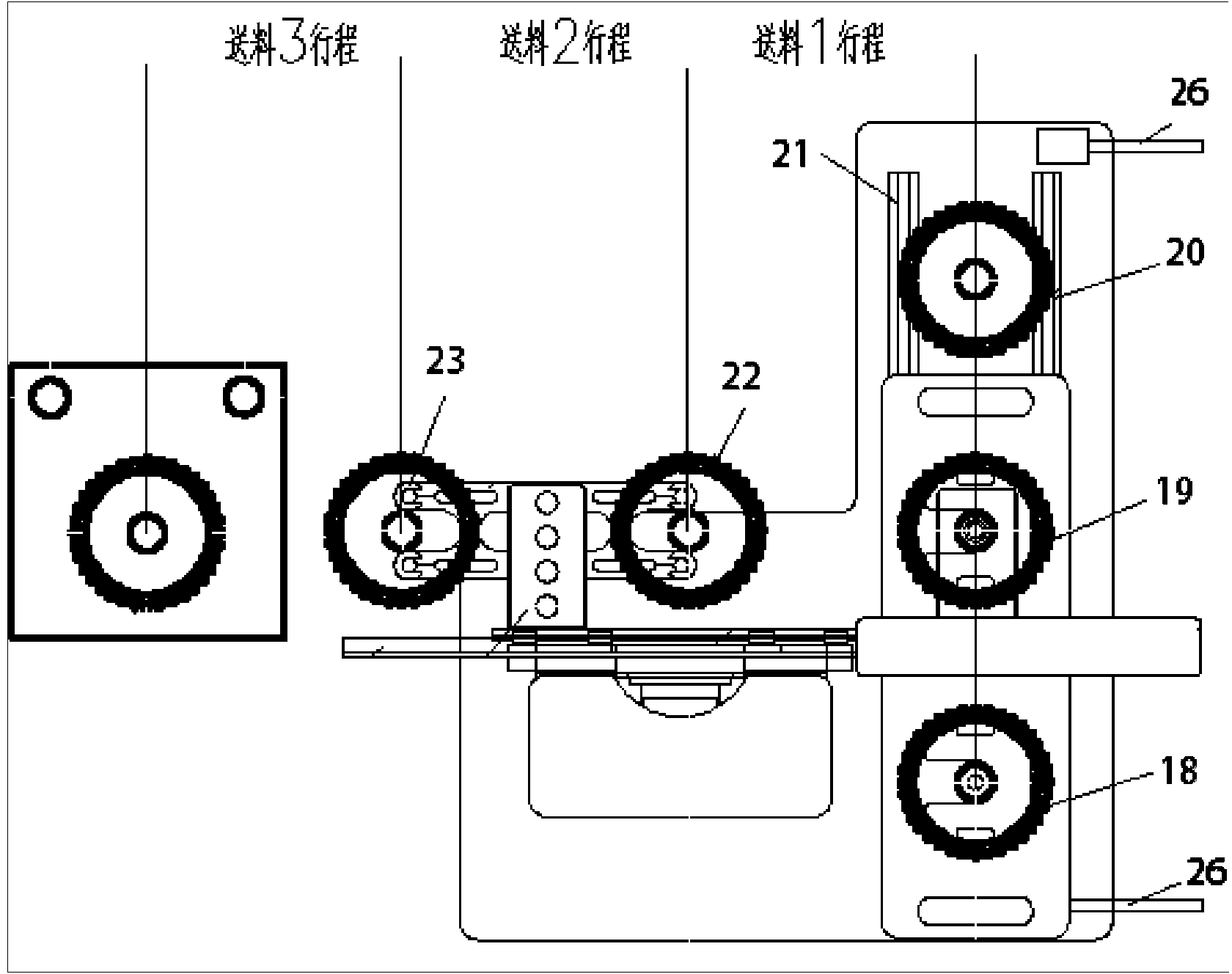

[0018] The present invention as figure 1 with figure 2 As shown, it includes a pre-embedded screw 2 with one end placed in the foundation 1, the pre-embedded screw 2 supports the frame body 3 on the foundation 1, the frame body 3 is set facing the punch workbench, and the side of the frame body 3 is provided with adjustment Access door 4, open and adjust Access door 4 can adjust and overhaul various equipment installed in the frame main body 3, station switch positioning 5 is installed on the upper surface of the frame main body 3, incremental mechanism 6 power and transmission part Installed on the bottom plate inside the frame main body 3, the part of the frame body carrying the punches is exposed from the upper surface of the frame body 3 and can move up and down, so as to ensure that the punches stacked in a stack on the work station 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com