Mold for forming hollow static blade flow guide core of light-weight gas turbine engine turbine

A technology for gas turbines and stationary blades, applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of complex processing procedures, difficulty in unifying individual size and profile deviations, etc., and achieve simplified preparation procedures, simple operations, Guaranteed the effect of external dimensions and line deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

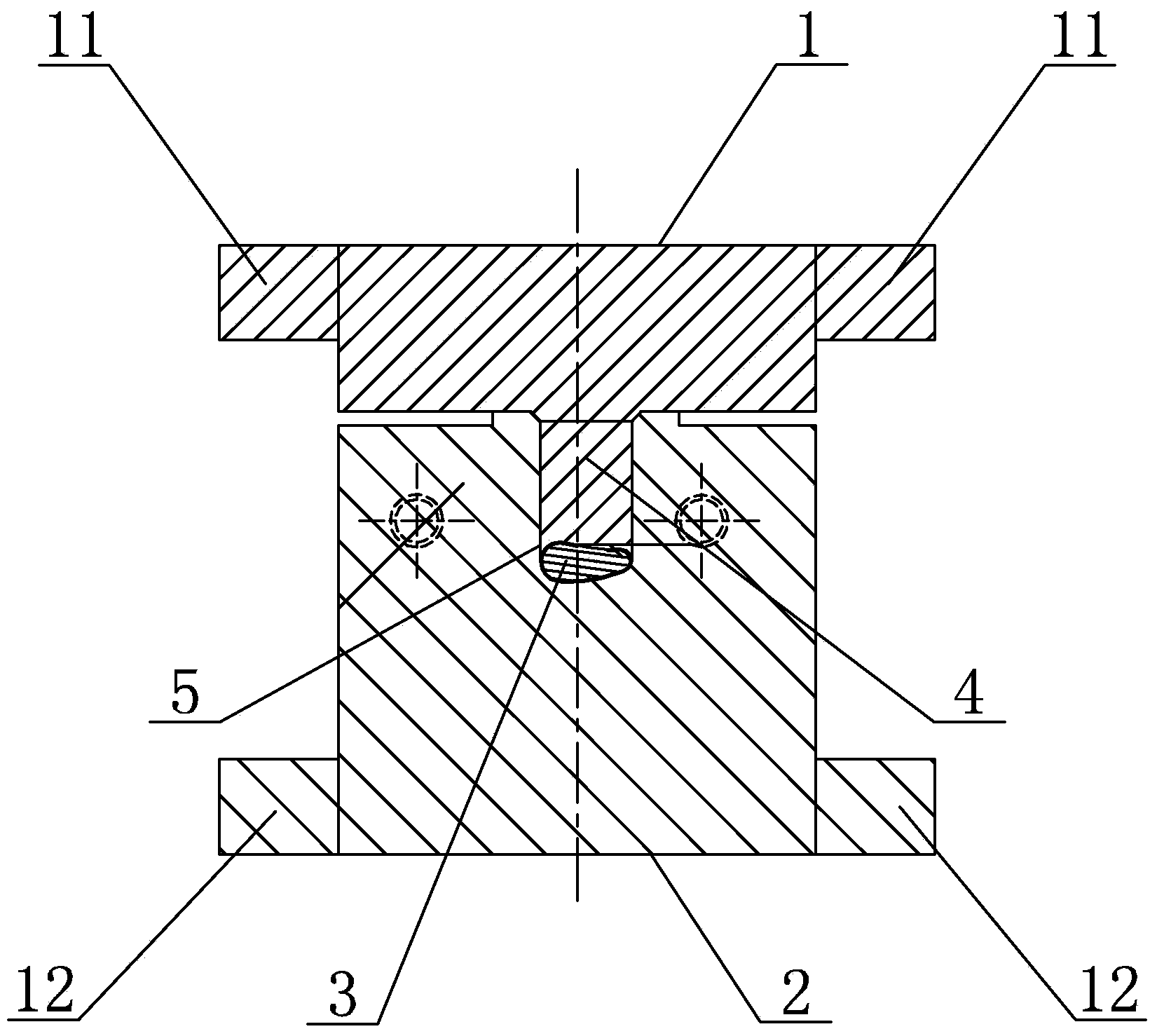

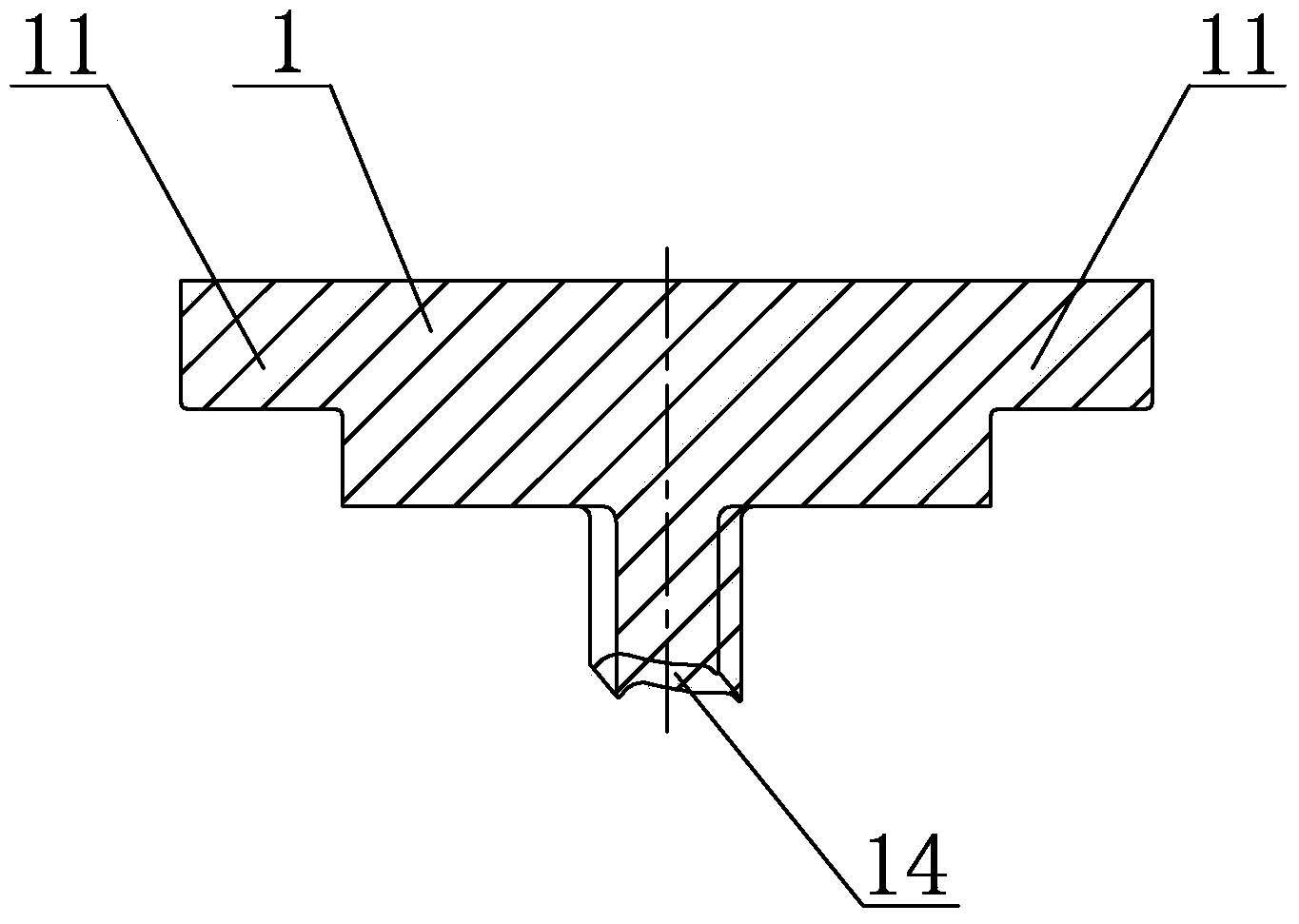

[0012] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 This embodiment is described. In this embodiment, a light-duty gas turbine turbine hollow vane guide core molding mold includes a convex module 1, a concave module 2 and a mandrel 3, and a convex edge is processed on the lower end surface of the convex module 1. 4. The lower end surface of the rib 4 is the first curved surface 14, and the upper end surface of the concave module 2 is processed with a groove 5 that matches the rib 4 on the convex module 1, and the groove bottom of the groove 5 It is the second curved surface 15 , when the male module 1 is fastened with the female module 2 , when the convex rib 4 is in the groove 5 , the mandrel 3 is located in the groove 5 and has a gap with the convex rib 4 .

[0013] The raw material for manufacturing the diversion core in the present invention is a preformed high temperature all...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 To illustrate this embodiment, the mold for forming the guide core of a light-duty gas turbine turbine hollow stator vane described in this embodiment also includes two auxiliary limit blocks 6, and two auxiliary limit blocks 6 are fixedly connected to the upper end surface of the concave module 2. The limit block 6, the two auxiliary limit blocks 6 are respectively located on both sides of the groove 5. In this embodiment, the two auxiliary limit blocks 6 are provided for the convenience of mold ejection. After stamping and forming using the present invention, there is a gap between the convex module 1 and the concave module 2 through the two auxiliary limit blocks 6, and the gap makes the convex module 1 The separation between the module 1 and the concave module 2 is easier, which facilitates the smooth progress of the proc...

specific Embodiment approach 3

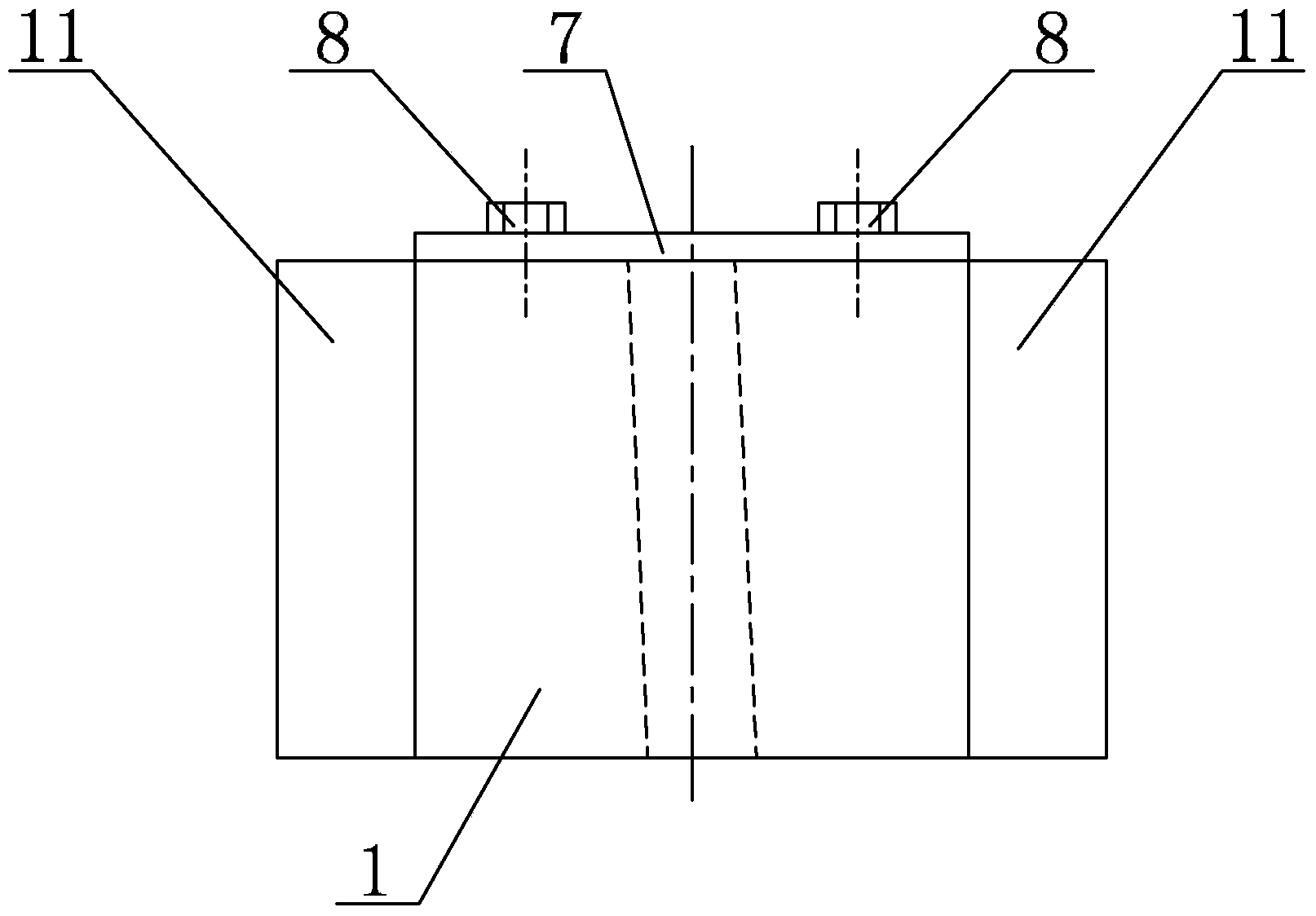

[0017] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 To illustrate this embodiment, a light-duty gas turbine turbine hollow stator vane guide core molding mold in this embodiment also includes a baffle 7, when the convex module 1 and the concave module 2 are engaged, the baffle 7 can be Disassemble the connection on the same side of the male module 1 and the female module 2. The setting of the baffle 7 is to make the position between the convex module 1 and the concave module 2 stable and not easy to misalign when the male module 1 and the female module 2 are in the buckled state to stamp the mandrel 3 with the preformed superalloy steel cylinder . The processing accuracy of the processed flow guiding core is effectively guaranteed. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com