Solid ultrasonic coupling agent and preparation method thereof

An ultrasonic coupling agent and coupling agent technology, applied in the direction of echo/ultrasonic imaging agent, etc., can solve problems such as inconvenience, complicated design and use of focused ultrasonic devices, and electrical safety hazards of focused ultrasonic emitting devices, and achieve smooth and clean surfaces and storage And easy to use and economical, good effect of ultrasonic transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

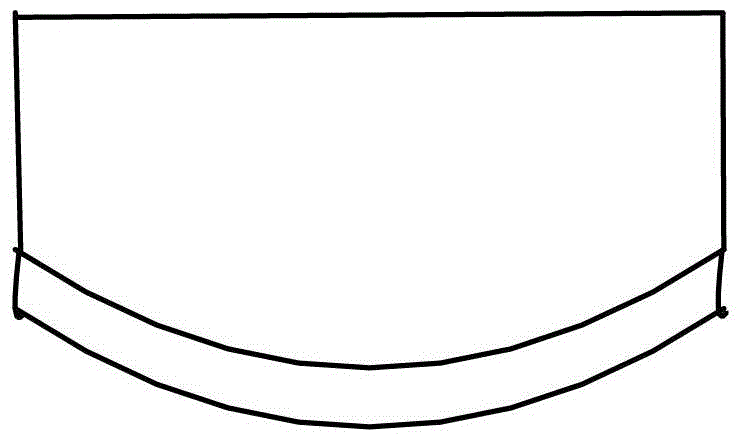

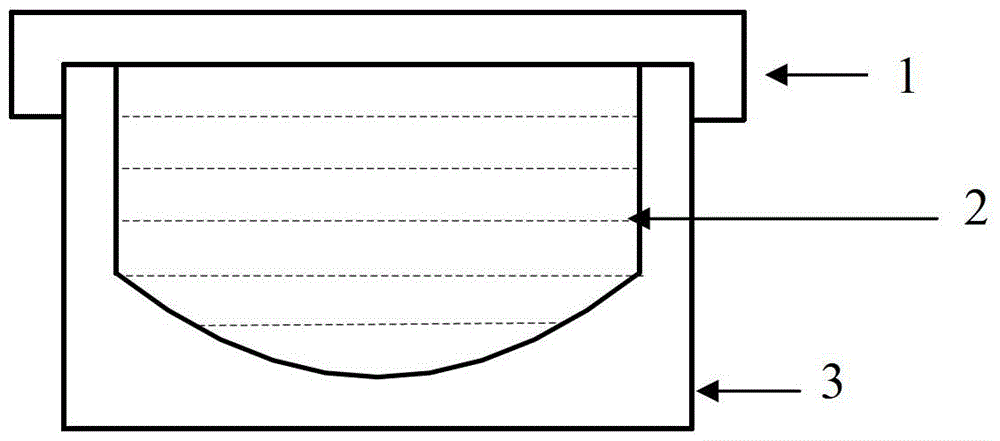

[0058] Content 70% of glucomannan, viscosity 5000mPa · s, grain size 120 mesh food grade konjac powder are dissolved in purified water to obtain 8% aqueous solution of konjac powder. The temperature of the whole dissolution process is controlled at about 45°C. Put the aqueous solution of konjac powder under the vacuum condition of temperature 45°C and -0.09Mpa for 24 hours to fully defoam. Under the condition of vacuum stirring, sodium hydroxide aqueous solution is added into the aqueous solution of konjac fine powder, so that the pH value of the aqueous solution of konjac fine powder rises to 11, and its mass concentration drops to about 6% at the same time. The aqueous solution of alkalized konjac powder is poured into the forming mold, and then the sealed forming mold is placed in a constant temperature box. Slowly heat to 75°C at a rate of 5°C per minute and hold for 3 hours. Pour the cured couplant out of the mold, soak it in clean water for cleaning, rinse and change t...

Embodiment 2

[0060] Content 78% of glucomannan, viscosity 7000mPa·s, grain size 100 mesh food grade konjac powder are dissolved in purified water to obtain 6% aqueous solution of konjac powder. The temperature of the whole dissolution process is controlled at about 30°C. Put the aqueous solution of konjac powder under the vacuum condition of temperature 30°C and -0.09Mpa for 30 hours to fully defoam. Under the condition of vacuum stirring, sodium carbonate aqueous solution is added into the aqueous solution of konjac fine powder, so that the pH value of the aqueous solution of konjac fine powder rises to 10, and its mass concentration drops to about 5% at the same time. The aqueous solution of alkalized konjac powder is poured into the forming mold, and then the sealed forming mold is placed in a constant temperature box. Slowly heat to 90°C at a rate of 5°C per minute and hold for 2 hours. Pour the cured coupling agent out of the mold, soak and clean it in clean water, rinse and change ...

Embodiment 3

[0062] Content 85% of glucomannan, viscosity 10000mPa·s, particle size 80 mesh food grade konjac powder are dissolved in purified water to obtain 2% aqueous solution of konjac powder. The temperature of the whole dissolution process is controlled at about 10°C. Put the aqueous solution of konjac powder under the vacuum condition of temperature 10°C and -0.09Mpa for 36 hours to fully defoam. Under the situation of vacuum stirring, sodium carbonate powder is added in the aqueous solution of konjac fine powder, and the pH value of the aqueous solution of konjac fine powder is raised to 9. The aqueous solution of alkalized konjac powder is poured into the forming mold, and then the sealed forming mold is placed in a constant temperature box. Slowly heat to 100°C at a rate of 5°C per minute and hold for 1 hour. Pour the cured couplant out of the mold, soak it in clean water for cleaning, rinse and change the water every 1 hour. After 5 times, the soaking water was tested to be n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| sound velocity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com