Temperature triggered ejection system and rework method for latch solder type components

A technology of ejection system and ejection direction, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following discussion, a lot of specific details are provided to help thoroughly understand the present invention. However, it is obvious to those skilled in the art that even without these specific details, it does not affect the understanding of the present invention. And it should be realized that any specific terms below are used only for convenience of description, therefore, the present invention should not be limited to be used only in any specific application represented and / or implied by such terms.

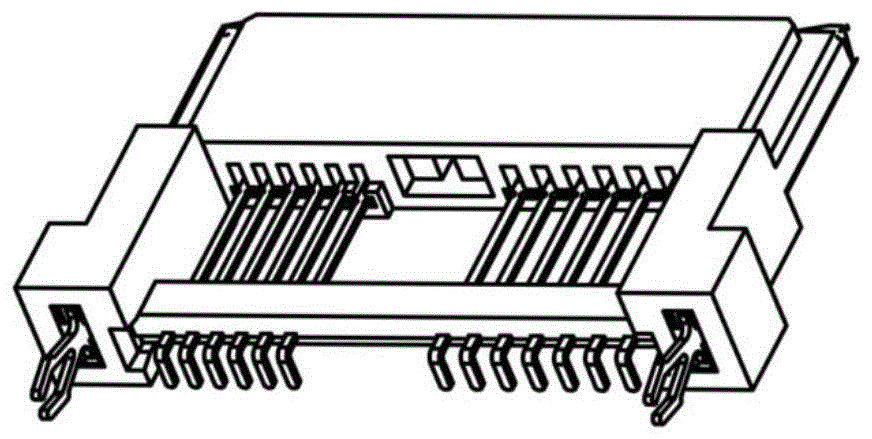

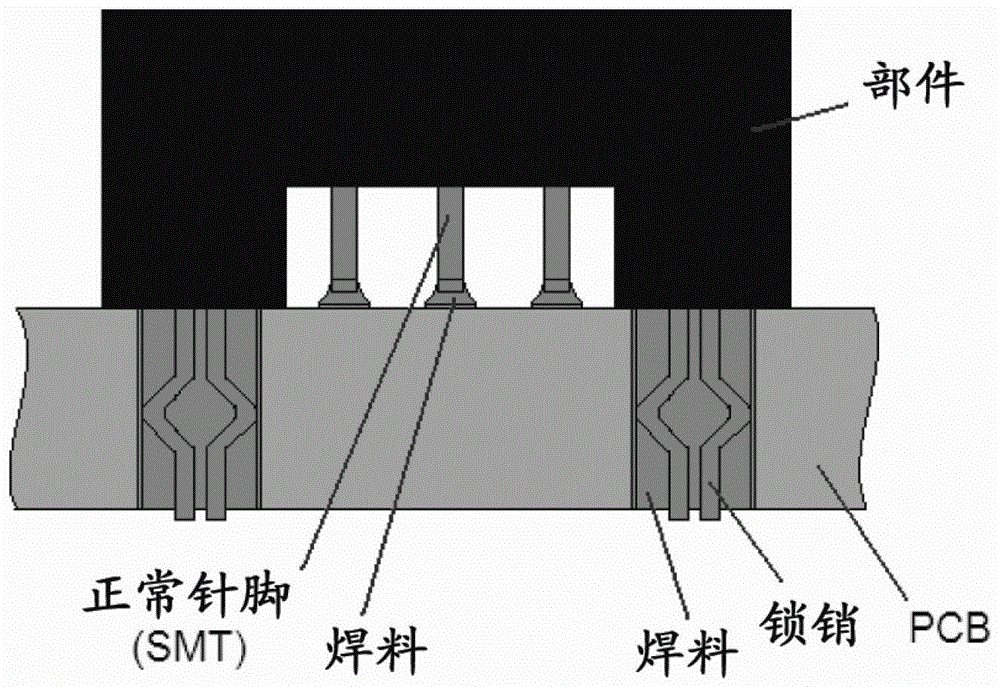

[0026] Even though figure 1 with figure 2 Two shapes of lock pins are shown in and will be used in the following embodiments figure 2 The shape of the lock pin in is described as an example, but it should be understood that the term "lock pin" used herein is not limited to this, as long as it is a similar locking mechanism that can increase the friction force, it can be applied Object of the invention.

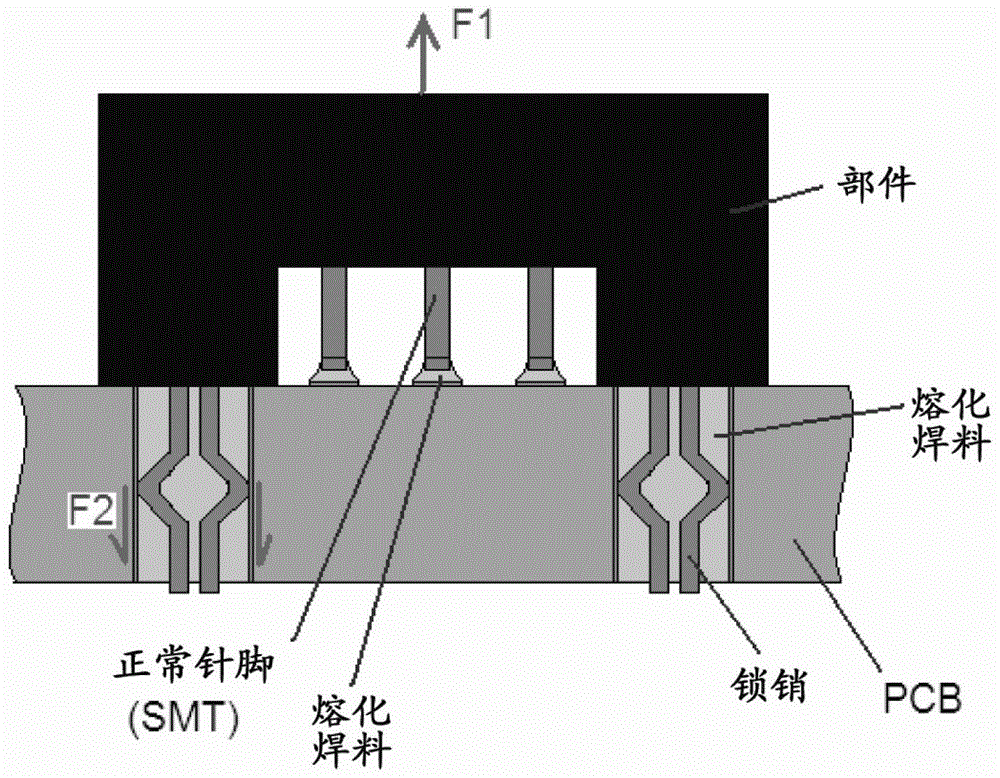

[0027] Figure 4 It is a schematic diagram showing a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com