Direct-current motor

A technology of DC motors and iron core groups, which is applied in the manufacture of motor generators, electric components, electrical components, etc. It can solve the problems of limited space utilization and increase the overall size, so as to improve power output efficiency, save energy, and flexibly adjust sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

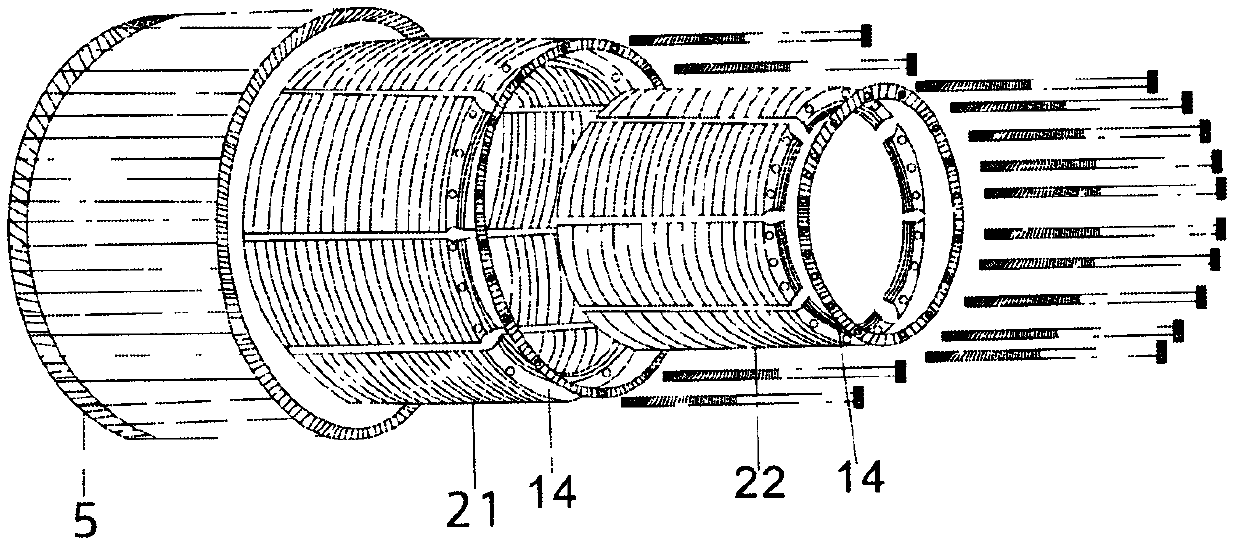

[0018] Firstly, the electromagnetic coil is wound on a single silicon steel sheet core, and then each single iron core is used as a stator core group. A steel ring with screw holes 14 is placed on the whole ring core group, and the stator core group 2 is fixed on the stator base 5 through bolts passing through the screw holes; A ring permanent magnet group, each full ring permanent magnet is provided with a fixed steel ring 9, and each full ring permanent magnet is fixed on the rotor base 6 through a bolt passing through a screw hole; on the back of the base, the connecting shaft 3 and the rotor base 6 fixed.

[0019] Insert the rotor into the stator core based on the concentric axis. Insert bearing 4 in the annular space of stator base 5 and rotor shaft head 10, then clip ring 8 in the annular draw-in groove of stator base 5 and bearing 4 outer edge, prevent bearing 4 from slipping out. On the rotor shaft head 10 with screw holes, put the flange 7 to align with the screw ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com