A rack and pinion driven cable stripping and rotating parallel crimping mechanism

A rack and pinion and cable technology, which is applied in the direction of connection and connection through deformation, can solve the problems of poor crimping quality, large power consumption, and large overall structure, and achieves convenient operation, low overall power consumption, and cable compression. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

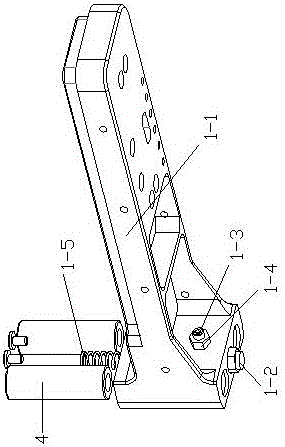

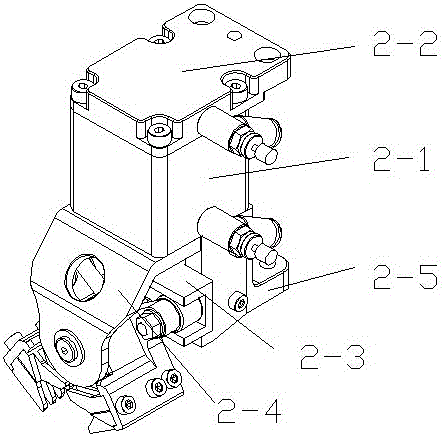

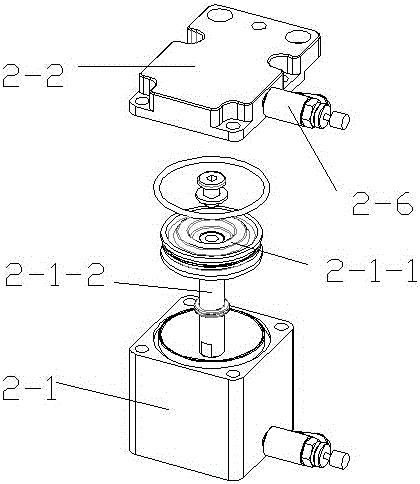

[0026] Example: such as figure 1 As shown, a rack-and-pinion driven cable peeling and rotating parallel crimping mechanism includes a swing arm unit 1, a pneumatic gripper unit 2 and a rack and pinion drive unit 3. The swing arm unit 1 connects with the pneumatic gripper through a linear bearing 4. The hand unit 2 is connected, and the rack and pinion drive unit 3 is fastened with the swing arm unit 1 by screws.

[0027] Such as figure 2 As shown, the swing arm unit 1 includes a swing arm 1-1, and the rear of the swing arm 1-1 is symmetrically provided with through holes for the linear bearing 4 to pass through. An adjustment screw 1-2 is arranged on the lower end surface of the rear portion of the swing arm 1-1, and the adjustment screw 1-2 is located in the middle of the two through holes. The inner surface of the rear part of the swing arm 1-1 is provided with a fastening screw 1-3 and its matching fastening nut 1-4, and the fastening screw 1-3 and its matching fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com