IC removing device

A technology for removing liquid and positioning the platform, which is applied in the field of machinery, can solve the problems of reducing processing efficiency, increasing operating time, and burns of staff, and achieves the effects of improving processing efficiency, avoiding glass breakage, and reducing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

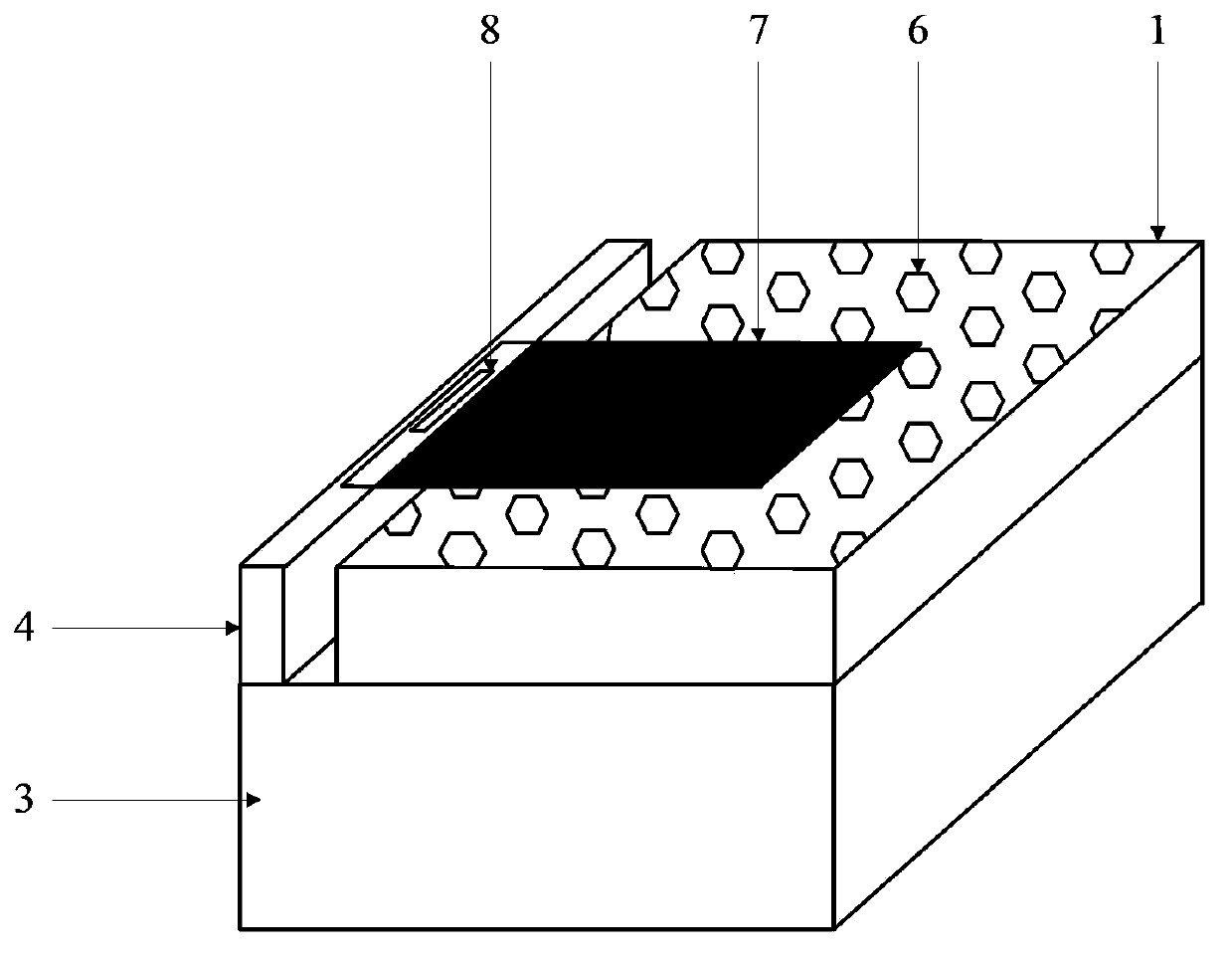

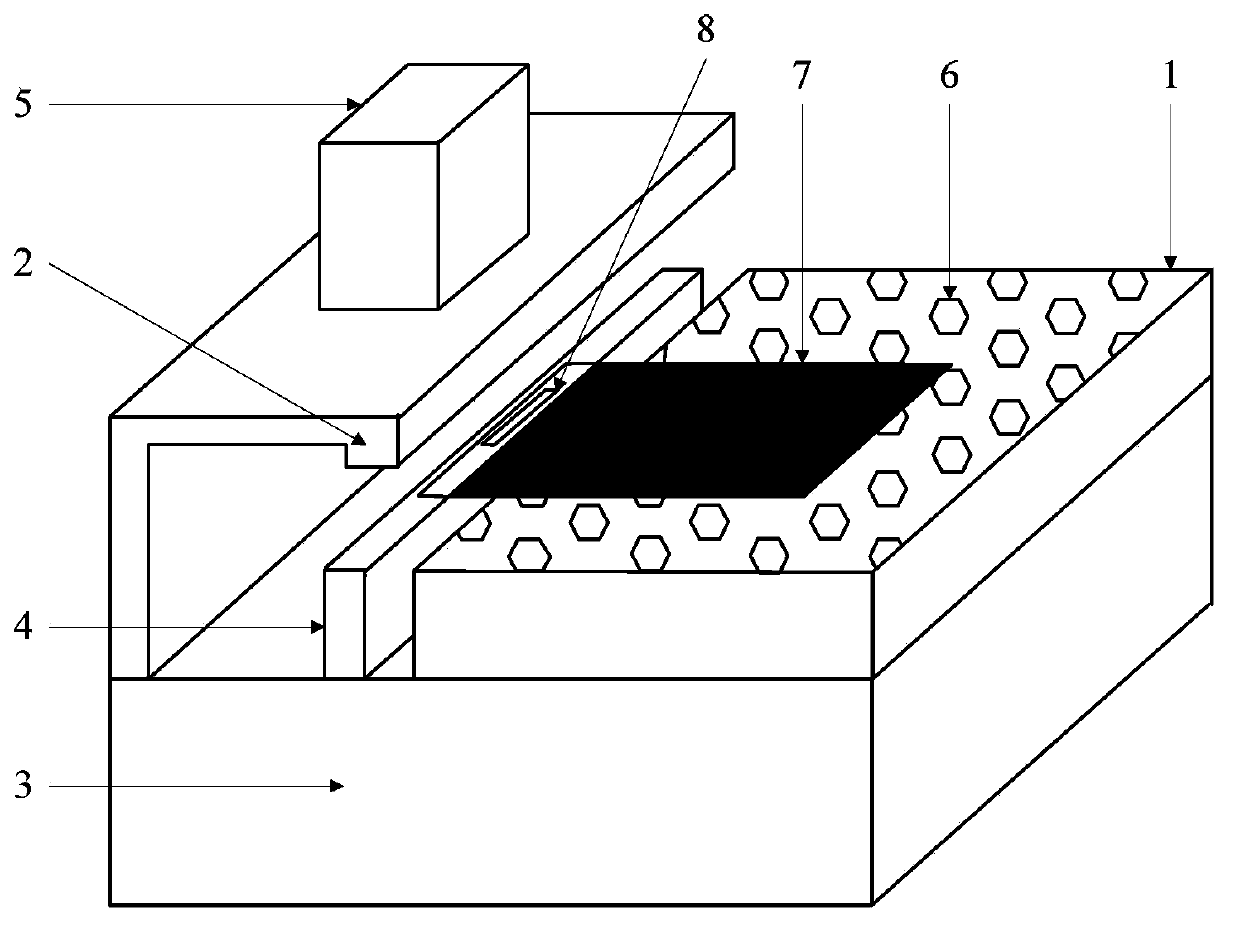

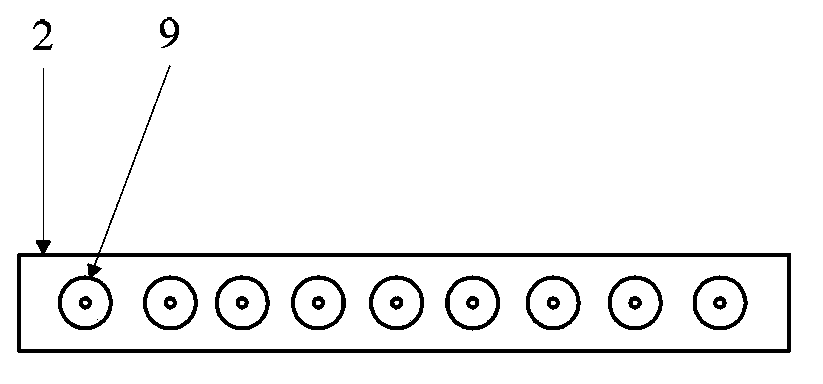

[0024] Such as figure 1 In , both the heater 4 and the positioning platform 1 are set on the operation controller 3 . Liquid crystal panels can be placed on the positioning platform 1 to wait for the processing part 7, and the processing part 7 can be protruded out of the positioning platform 1, so that the IC8 on the processing part 7 can be positioned at a position that can be heated by the heater 4 (attached or close to the heater) 4 all can be), such as: be positioned at the top of heater 4.

[0025] The operation controller 3 can control the opening and closing of the heater 4, and can also control the heating temperature of the heater 4. When the operation controller 3 controls the heater 4 to turn on, the heater 4 can heat the IC8. After a period of heating, the glue used to fix the IC8 on the workpiece 7 is softened, so the IC8 can be removed from the workpiece 7 with a tool. Remove the processing part 7 to realize the removal of IC8.

[0026] The instrument for tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com