Low-temperature internal pressure test assessment method for low-temperature storage tanks in the state of non-insulated structure

A low-temperature storage tank and internal pressure test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of long storage tank repair welding and repair period, storage tank thermal insulation structure damage, and difficult state inspection. Achieve the effect of optimizing design and optimization, increasing environmental coverage, improving operability and standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034] The low-temperature internal pressure test assessment of the low-temperature storage tank without the insulation structure means that after the production of the metal box of the low-temperature storage tank is completed, the low-temperature internal pressure test is directly carried out without the construction of the thermal insulation structure. The low-temperature storage tank refers to the loading liquid For oxygen or liquid hydrogen propellant tanks, the test implementation method is as follows:

[0035] Step (1), build the test system, the specific method is as follows:

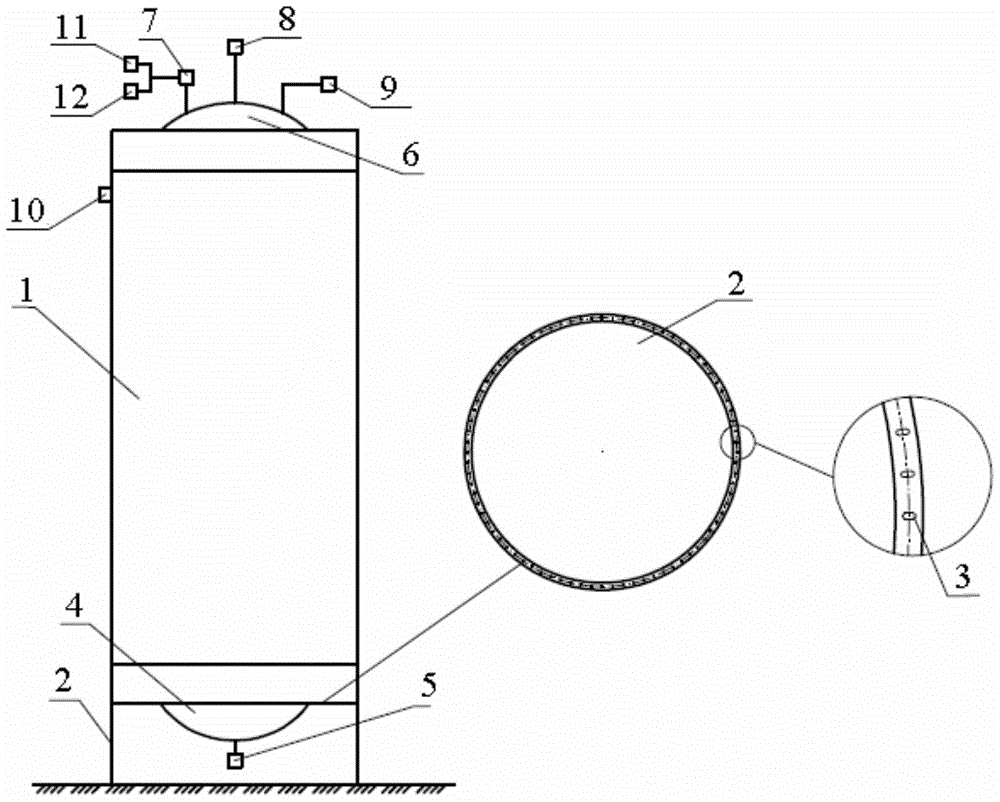

[0036] (1), such as figure 1 Shown is a schematic structural diagram of the test system built in the low-temperature internal pressure test of the present invention. The low-temperature storage tank 1 to be assessed is placed upright, the lower end surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com