An online near-infrared analysis preprocessing device and method

A pretreatment device and near-infrared technology, applied in the field of ethylene cracking, can solve the problems affecting the light absorption of the sample, impurity adsorption, result deviation, etc., and achieve the effects of reducing environmental pollution, low manufacturing cost, and stable instrument baseline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

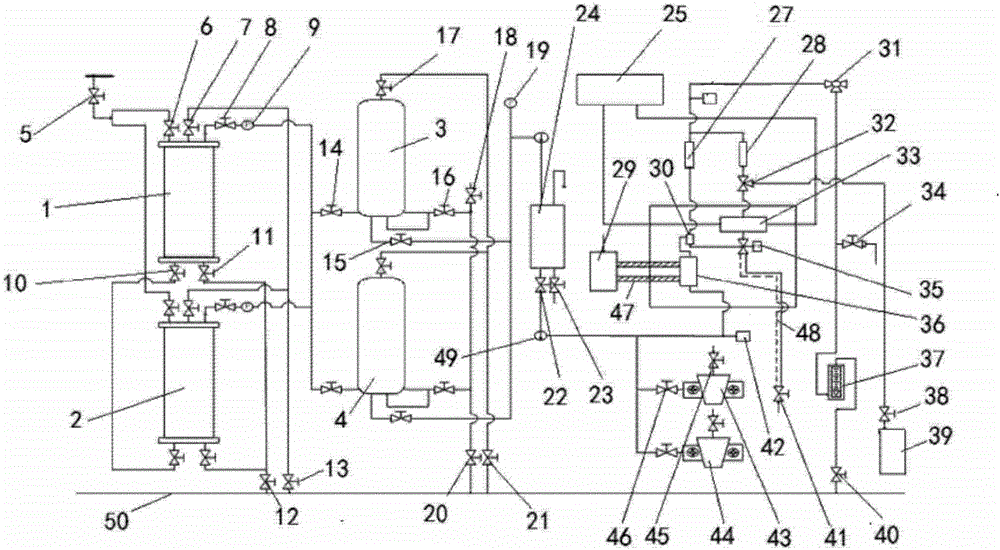

[0040] Example 1: Such as figure 1 , figure 2 , image 3 As shown,

[0041] The process of an online near-infrared analysis preprocessing device is as follows figure 1 As shown, the top end of the first-stage sedimentation filter 1 has a first valve 6, a second valve 7 and a third valve 8 connected; the bottom end of the first-stage sedimentation filter 1 has a fourth valve 10 and a fifth valve 11 connected , The other end of the third valve 8 is connected to the first meter 9;

[0042] The valve connection structure of the second-stage sedimentation filter 2 is the same as that of the first-stage sedimentation filter 1, and the valve of the second-stage sedimentation filter 2 is at the other end of the corresponding valve of the first-stage sedimentation filter 1. After connection: the other end of the second valve 7 is connected to the sixth valve 13, the other end of the fifth valve 11 is connected to the seventh valve 12, and the other end of the first valve 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com