Automatic leakage detecting device for household air conditioner finished products

An automatic inspection and air-conditioning technology, applied in the direction of measuring devices, electromagnetic radiation induction, instruments, etc., can solve the problems of manual error amplification, low detection efficiency, collisions, etc., and achieve high mechanization, high-efficiency opening effect, and improved detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

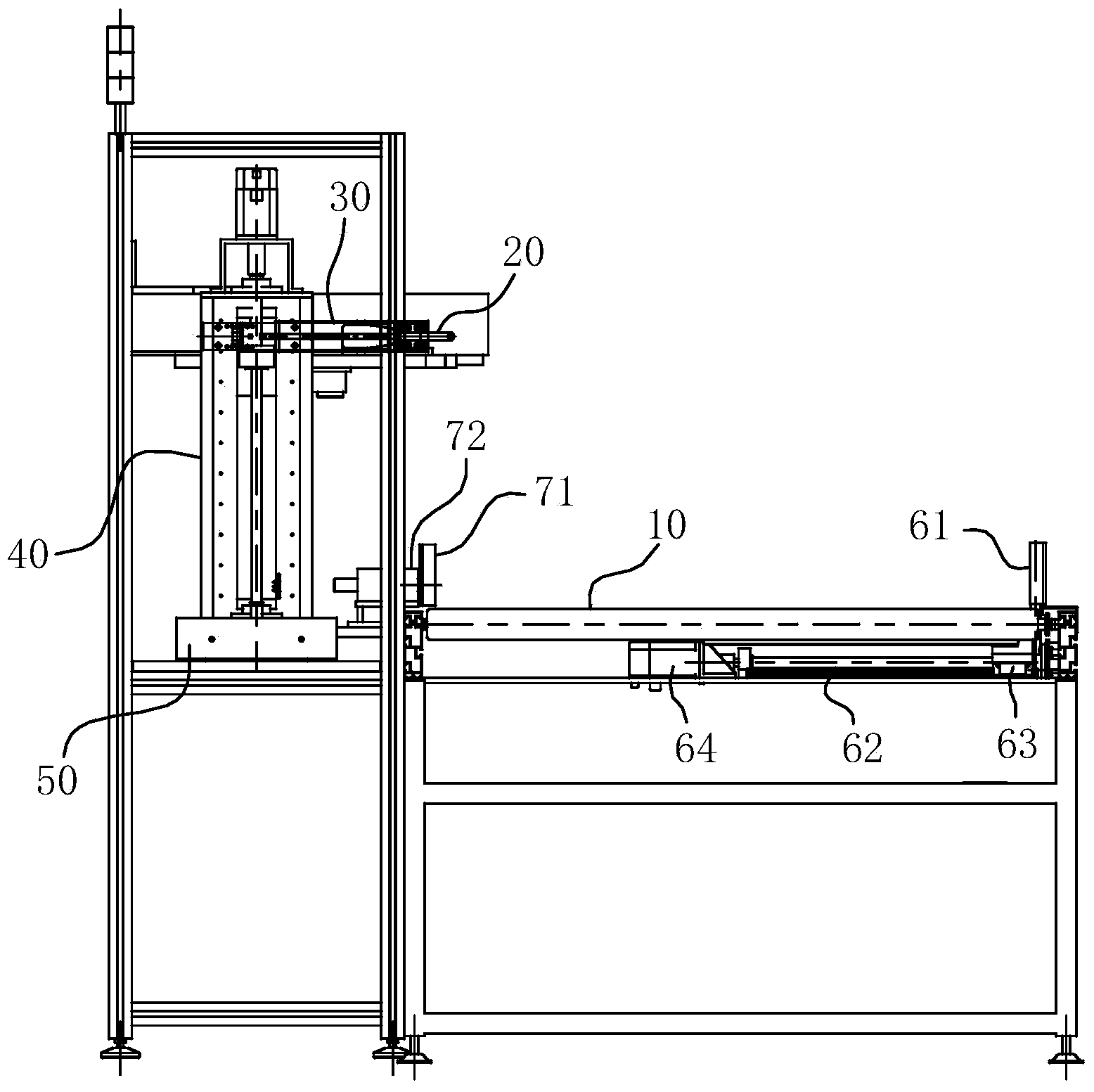

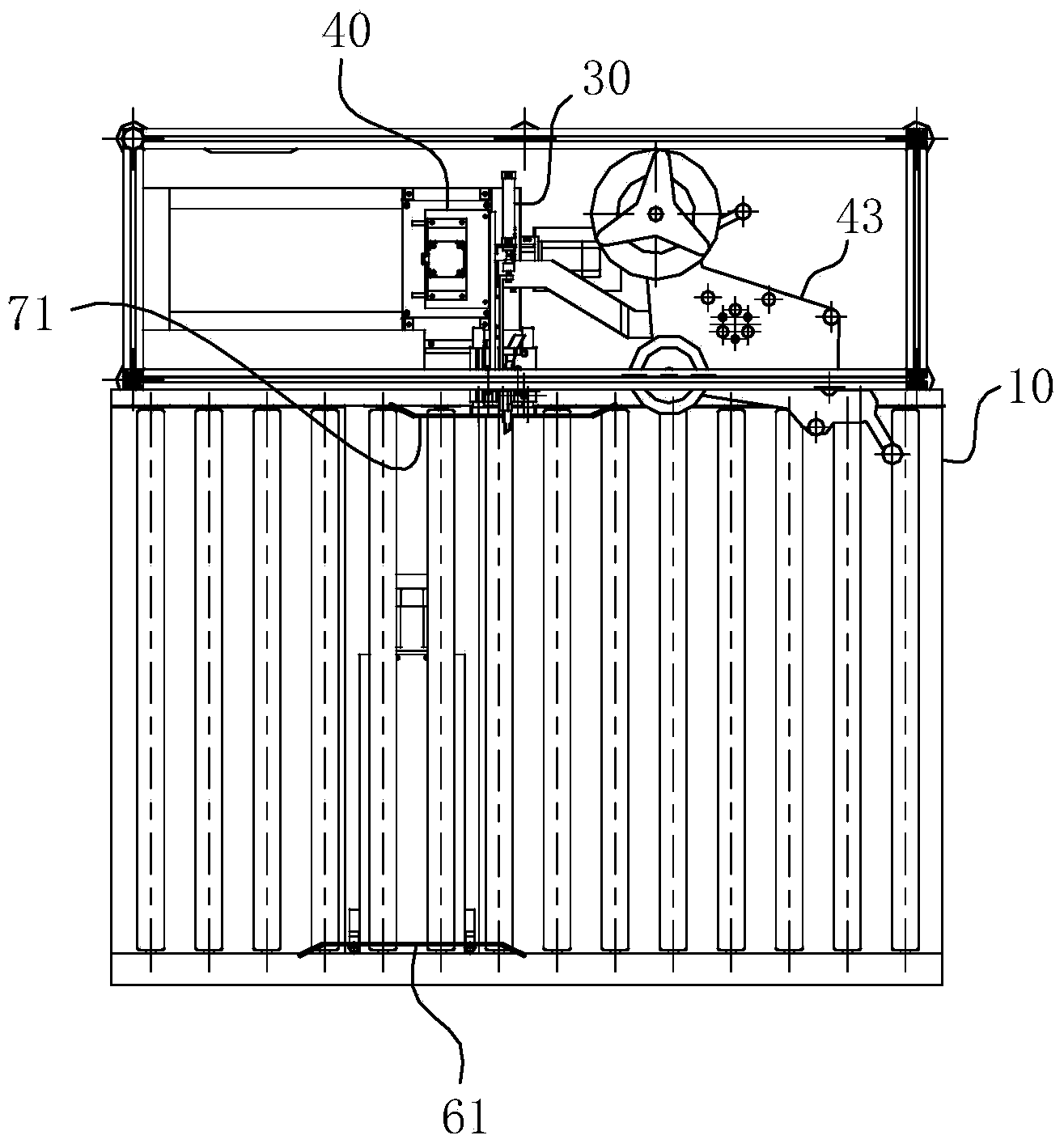

[0036] For ease of understanding, the specific structure of the present invention and its operation process are further described below in conjunction with the accompanying drawings:

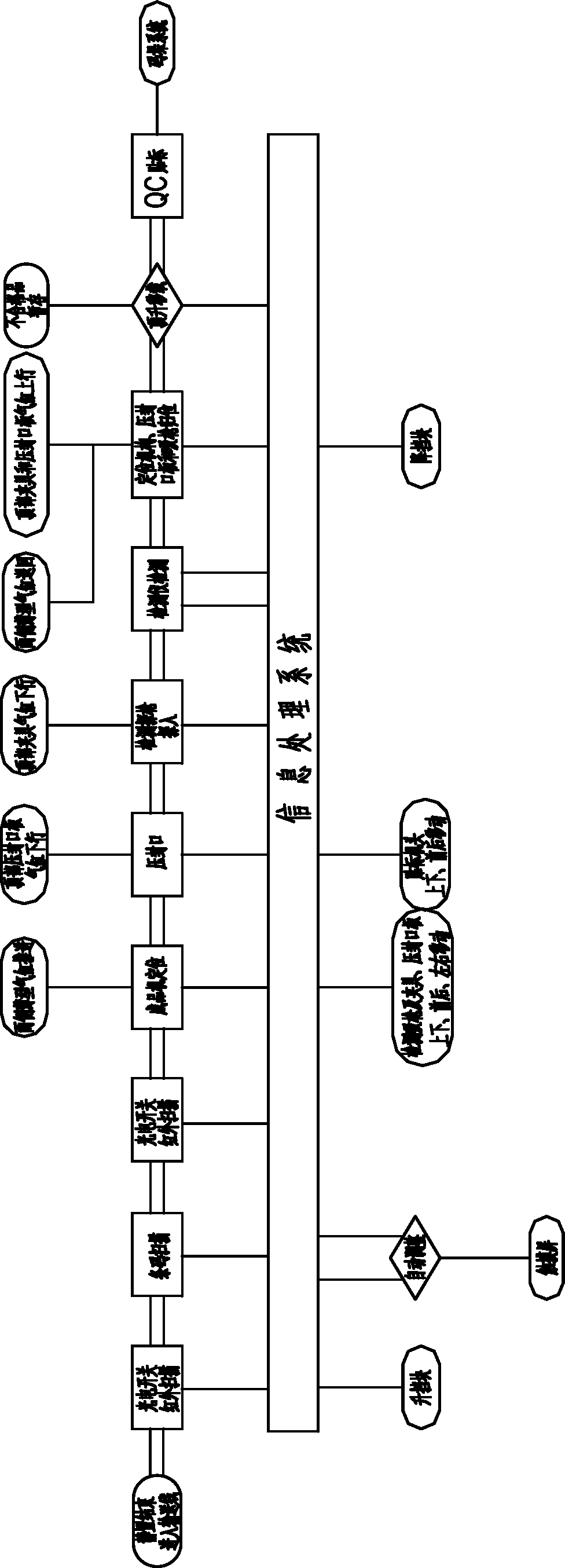

[0037] The concrete implementation structure of the present invention refers to Figure 1~6 As shown, it is mainly composed of conveying system, barcode and infrared scanning system, information processing system and so on.

[0038] 1), Conveying and transferring system:

[0039] The conveying system is composed of a power roller conveying mechanism (that is, a conveying platform 10), a pushing mechanism 30, a lifting mechanism 40, a translation mechanism 50, and a baffle mechanism (that is, a baffle assembly).

[0040] 1. Power roller conveying mechanism: It is composed of the driving device as the power source, the rollers constituting the conveying working surface, the sprocket chain linking each roller, the frame and the guide railing and other components. In this system, the motor reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com