Solution for achieving in-situ hole sealing on micro-arc oxidation coating on magnesium alloy surface and preparation method of micro-arc oxidation coating

A micro-arc oxidation and in-situ sealing technology, applied in the direction of anodic oxidation, can solve the problems of complex sealing treatment, affecting corrosion resistance, etc., and achieve the advantages of saving sealing treatment steps, long service life and high chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

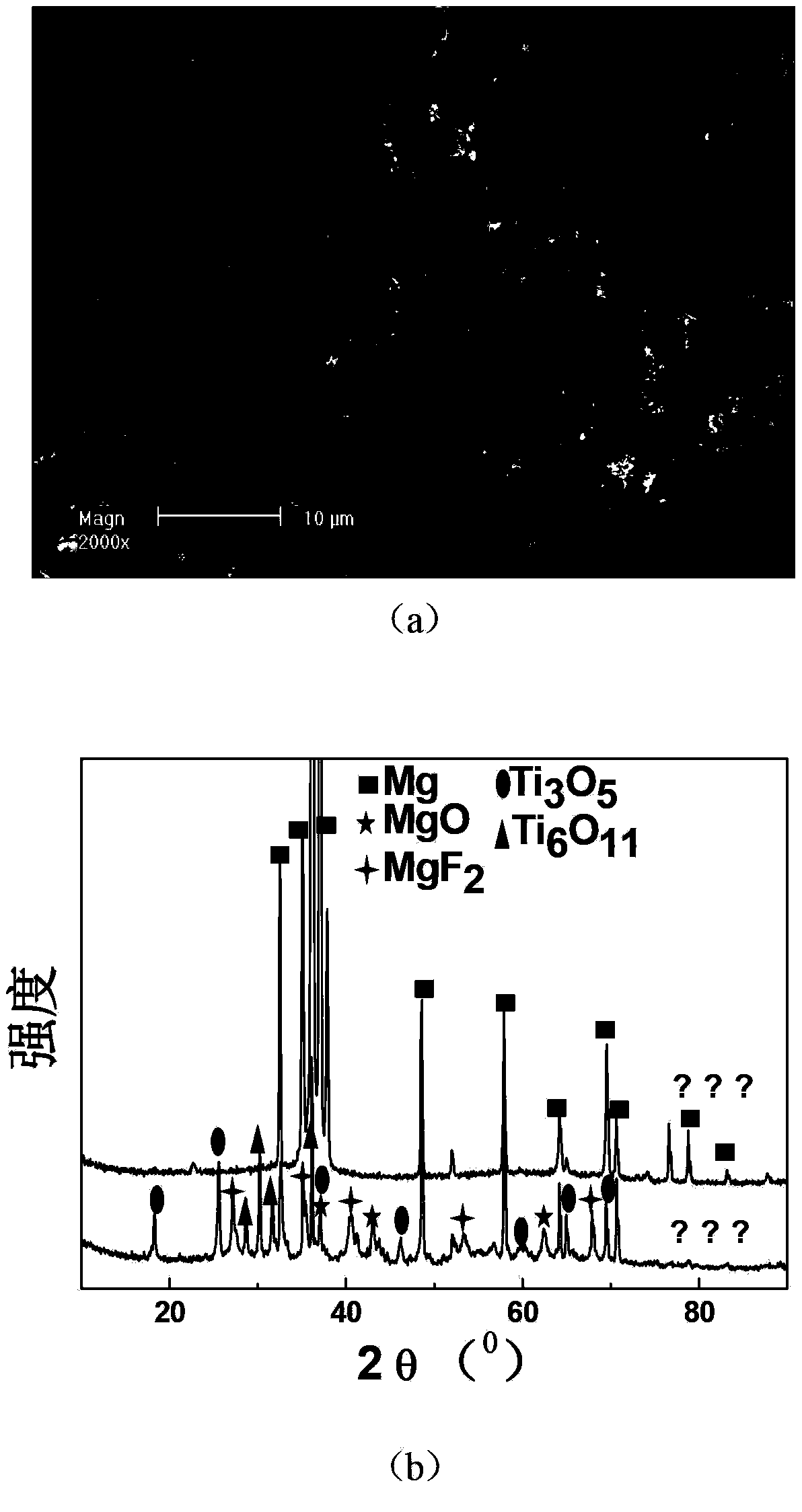

Image

Examples

Embodiment 1

[0030] The preparation process of a solution that can realize the in-situ sealing of micro-arc oxidation film on the surface of magnesium alloy is as follows: sodium fluorotitanate, potassium polyphosphate and potassium polymetaphosphate are respectively dissolved in appropriate amount of distilled water and mixed together to form a solution, and The concentration of each component in the solution is: 8g / L sodium fluotitanate, 3g / L potassium polyphosphate, 4g / L potassium polymetaphosphate. Then add sodium hydroxide to the above solution according to the addition amount of 5g / L (5g sodium hydroxide is added to each liter of solution), and after the white colloidal suspended particles are no longer precipitated, add polybutyl acetate additive, polybutyl acetate The additive amount is 0.05g / L. Sodium hydroxide was then added to adjust the pH to 5, and the resulting mixed slurry was allowed to stand for 1 day.

[0031] The sample is AM30 magnesium alloy. After sanding to remove ...

Embodiment 2

[0036] The preparation process of a solution that can realize in-situ sealing of micro-arc oxidation film on the surface of magnesium alloy is as follows: potassium fluorotitanate, sodium polyphosphate and ammonium polymetaphosphate are respectively dissolved with appropriate amount of distilled water and mixed together to form a solution. And the concentration of each component in the solution is: 5g / L potassium fluotitanate, 8g / L sodium polyphosphate, 1g / L ammonium polymetaphosphate. Then add ammonia water in the above-mentioned solution according to the addition amount of 2g / L, after the white colloidal suspension particle no longer precipitates, add polyurethane additive, the addition amount of polyurethane additive is 1g / L. Then add sodium hydroxide, adjust the pH to 8, and let stand for 1 day.

[0037] The sample is AZ91 cast magnesium alloy. After sanding to remove surface oxides and burrs, wipe with acetone to degrease.

[0038] The pretreated magnesium alloy workpie...

Embodiment 3

[0042] The preparation process of a solution capable of realizing the in-situ sealing of micro-arc oxidation film on the surface of magnesium alloy is as follows: dissolving ammonium fluorotitanate, sodium polyphosphate and sodium polymetaphosphate respectively with an appropriate amount of distilled water and mixing them together to form a solution, and The concentration of each component in the solution is: 11g / L ammonium fluorotitanate, 6g / L sodium polyphosphate, 2g / L sodium polymetaphosphate. Then potassium hydroxide was added to the above solution in an amount of 3g / L, and after white colloidal suspended particles were no longer precipitated, sodium polyacrylate additive was added, and the amount of sodium polyacrylate additive was 0.8g / L. Adjust the pH to 6.5 and let stand for 1 day.

[0043] The sample is AZ31 magnesium alloy. After sanding to remove surface oxides and burrs, wipe with acetone to degrease.

[0044] The pretreated magnesium alloy workpiece is clamped b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com