Sludge reduction and recycling treatment device and sludge treatment method

A treatment device and resource-based technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as large energy consumption, generation of sulfur dioxide, complex process, etc., to achieve Reduce treatment costs, achieve zero emissions, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

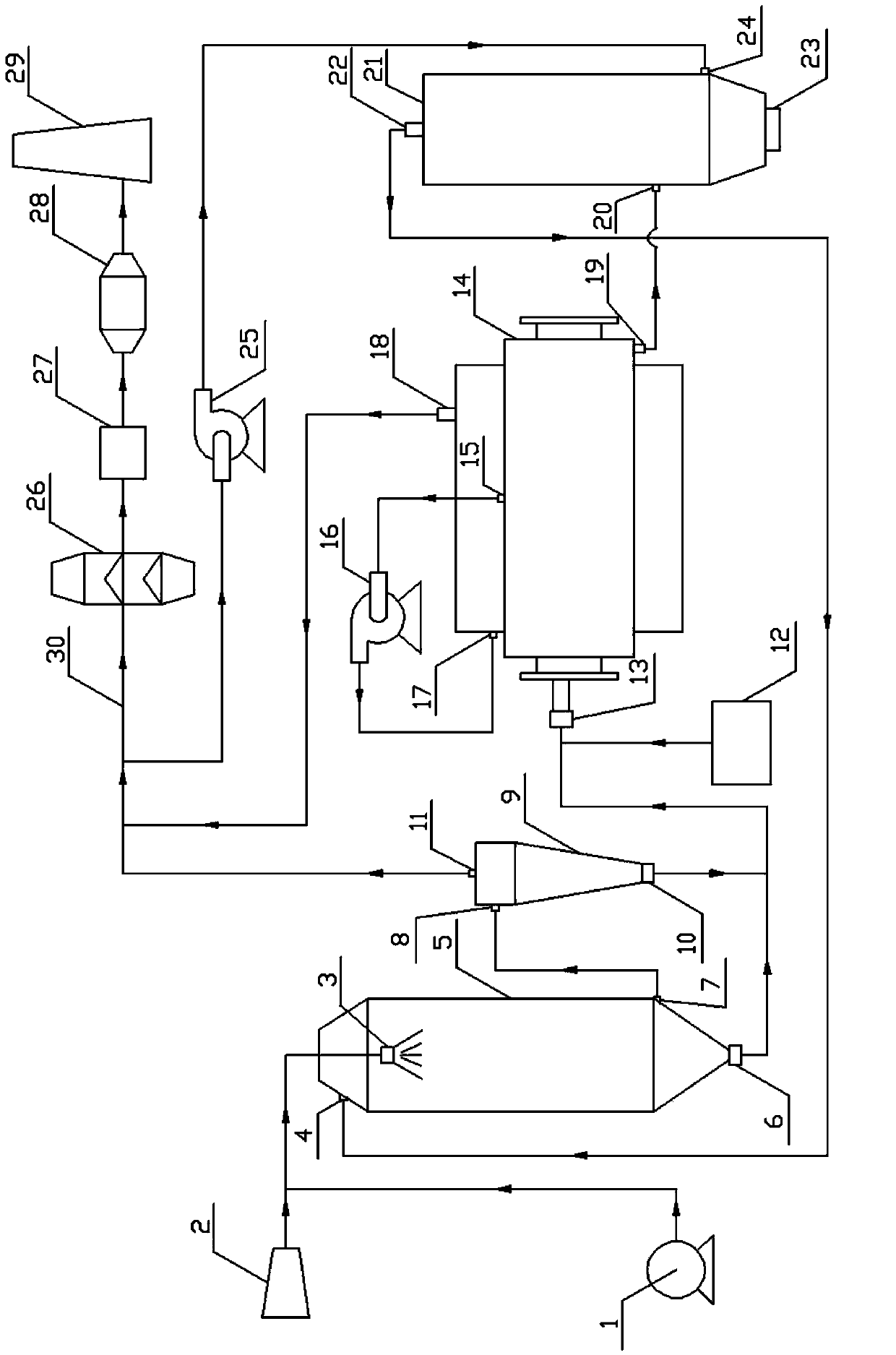

[0034] Example: such as figure 1 As shown, a sludge reduction resource treatment device, which connects the sludge pump 1 and the air compressor 2 with the atomizing nozzle 3 on the top of the spray drying tower 5, and the exhaust port 7 of the spray drying tower 5 is connected to the cyclone The air inlet 8 above the separator 9 is connected, and the discharge port 6 at the bottom of the spray drying tower 5 and the discharge port 10 at the bottom of the cyclone separator 9 and the coal box 12 are connected with the screw feeder 13 of the pyrolysis furnace 14. The material return outlet 15 of the pyrolysis furnace 14 is connected to the high temperature resistant fan 16, the high temperature resistant fan 16 is connected to the material return inlet 17 of the pyrolysis furnace 14, and the pyrolysis charcoal outlet 19 of the pyrolysis furnace 14 is connected to the incinerator inlet 20, The high temperature flue gas outlet 22 of the fluidized bed incinerator 21 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com