Method for catalytically synthesizing biomimetic material hydroxyapatite from phosvitin and polypeptide thereof

A phosvitin and hydroxyapatite technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of synthesis time limitation, long time, etc. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

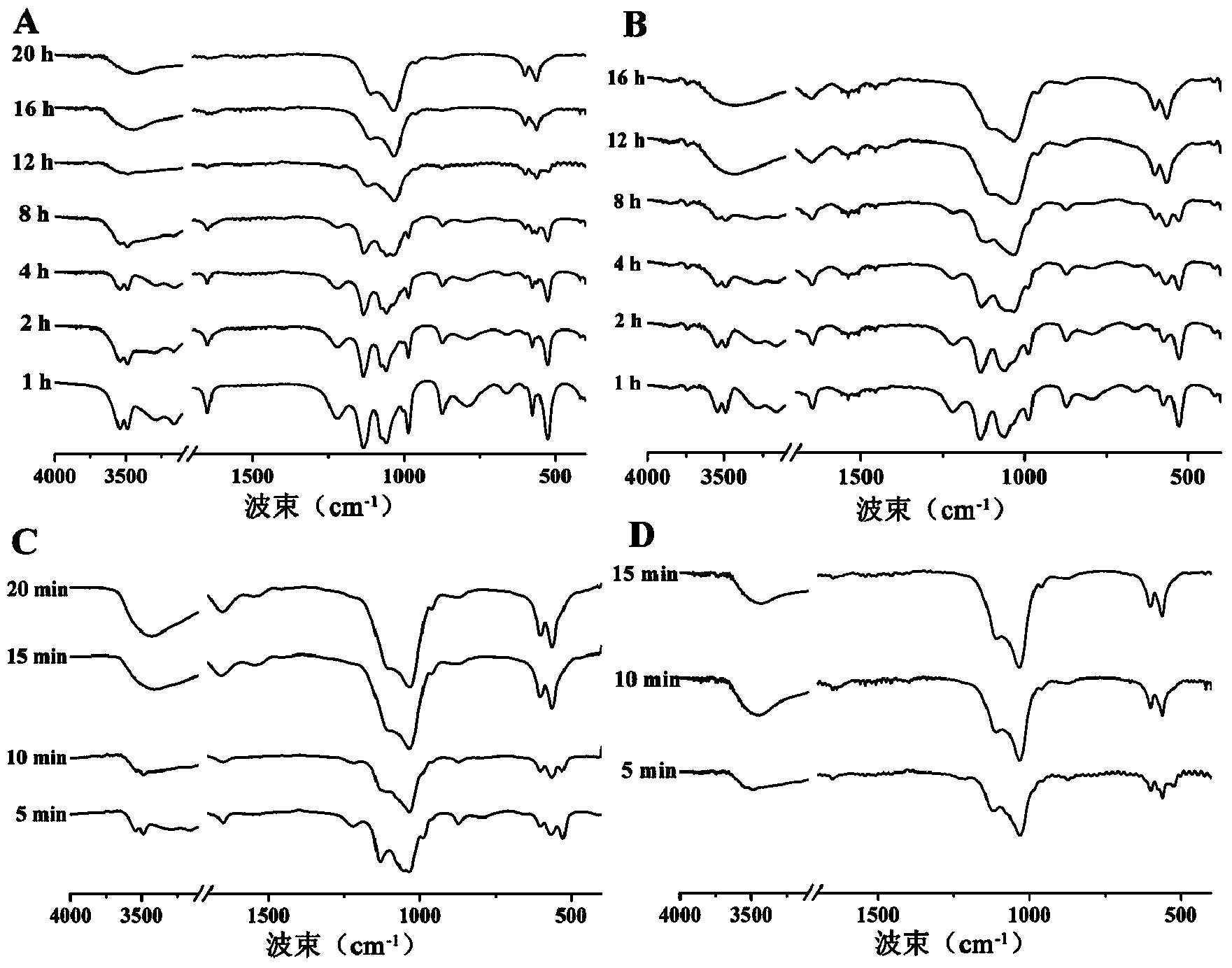

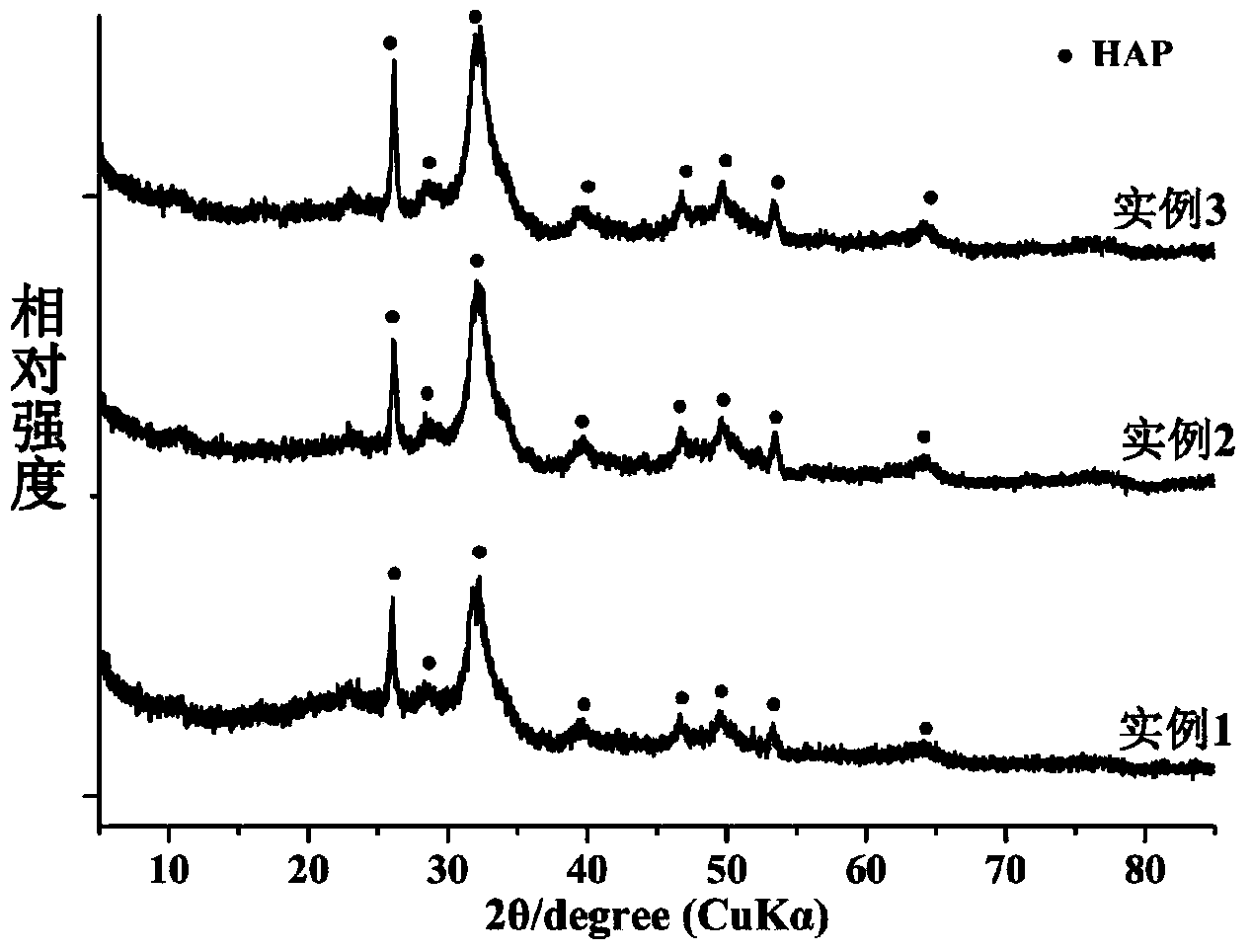

[0024] A method of utilizing phosvitin to catalyze the synthesis of biomimetic material hydroxyapatite:

[0025] After dissolving calcium chloride and potassium dihydrogen phosphate, react in a neutral solution under the catalysis of phosvitin, the molar ratio of calcium chloride and potassium dihydrogen phosphate is 3:1, and add 1 g of calcium ion per 3 mol of calcium ion Phosvitin. During the reaction process, 0.1 mol / L NaOH solution is continuously added dropwise to keep the pH of the system at 6.8-7.2. After 15 minutes of reaction, the precipitate is collected to obtain the hydroxyapatite mineralized material.

Embodiment 2

[0027] 1) Enzymatic hydrolysis of phosvitin: Dissolve phosvitin in 0.01mol / L NaOH solution, stir for 1 hour, adjust the pH of the solution to 2.2, add 1g of pepsin for every 50g of phosvitin, and perform enzymatic hydrolysis for 3 hours , and then adjust the pH of the solution to 7.5, then add 1 g of trypsin for every 20 g of phosvitin, and perform enzymatic hydrolysis for 5 hours. After the enzymatic solution is centrifuged, the supernatant is the phosvitin polypeptide mixture.

[0028] 2) Separation and purification of peptides: using Toyopearl DEAE-650M anion exchange chromatography, the filler balance buffer is Tris-HCl buffer with pH 7.2, after the supernatant is loaded, use sodium chloride concentrations of 0, 0.1, 0.2, 0.3, 0.4, 0.5 and 0.6 mol / L Tris-HCl buffer solution for gradient elution step by step, collect the eluate with a sodium chloride concentration of 0.2 mol / L, and perform desalination treatment according to the conventional ultrafiltration method. The mole...

Embodiment 3

[0031] (1) Enzymatic hydrolysis of phosvitin: take phosvitin and dissolve it in 0.1mol / L NaOH solution, stir for 0.5 hours, adjust the pH of the solution to 2.8, add 1g of pepsin per 100g of phosvitin, and enzymolyze 5 hour, then adjust the pH of the solution to 8.2, then add 1g of trypsin per 80g of phosvitin, and enzymatically hydrolyze for 8 hours. After the enzymatic solution is centrifuged, the supernatant is the phosvitin polypeptide mixture.

[0032] (2) Separation and purification of peptides: Q Sepharose FF anion exchange chromatography was used, and the filler equilibrium buffer was Tris-HCl buffer at pH 8.0. After loading the supernatant, Tris-HCl with a sodium chloride concentration of 0.5mol / L was used. The HCl buffer is used for elution, the eluate is collected, and after desalting treatment, the phosvitin polypeptide with biological activity is obtained.

[0033] (3) Catalytic synthesis: react calcium chloride and sodium dihydrogen phosphate under the catalysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com