Enclosed cable trolley

A closed and cable technology, applied in the direction of load suspension components, transportation and packaging, etc., can solve the problems of wheel jamming, easy accumulation of dust or ice and snow, etc., to avoid pulley jamming, reduce friction, and avoid axial movement moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

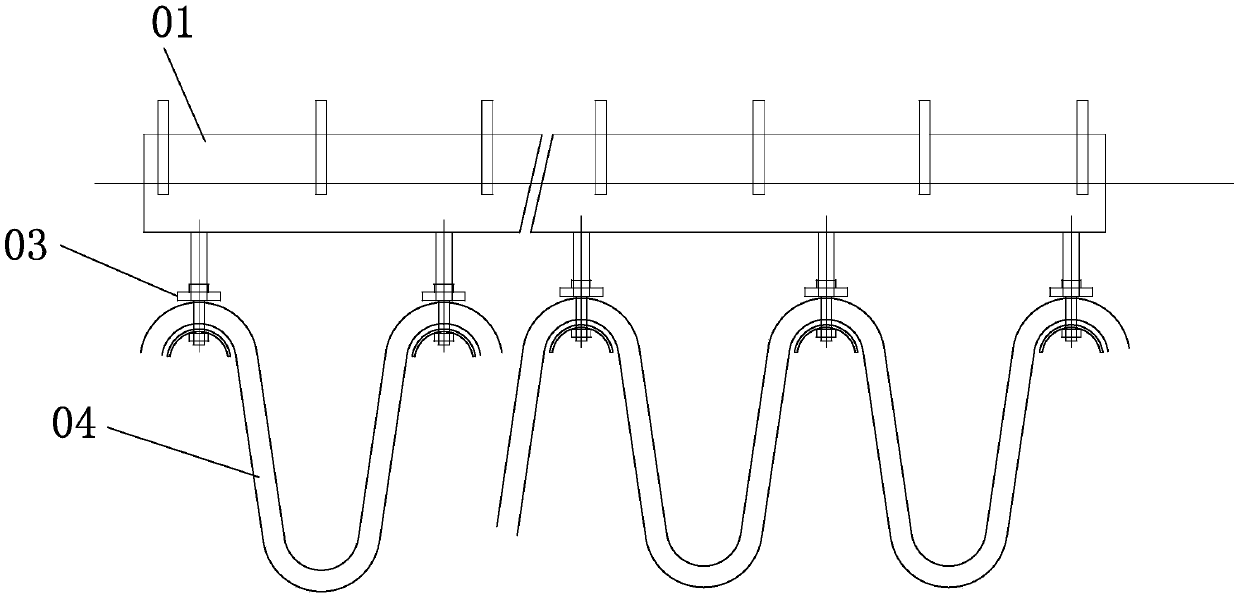

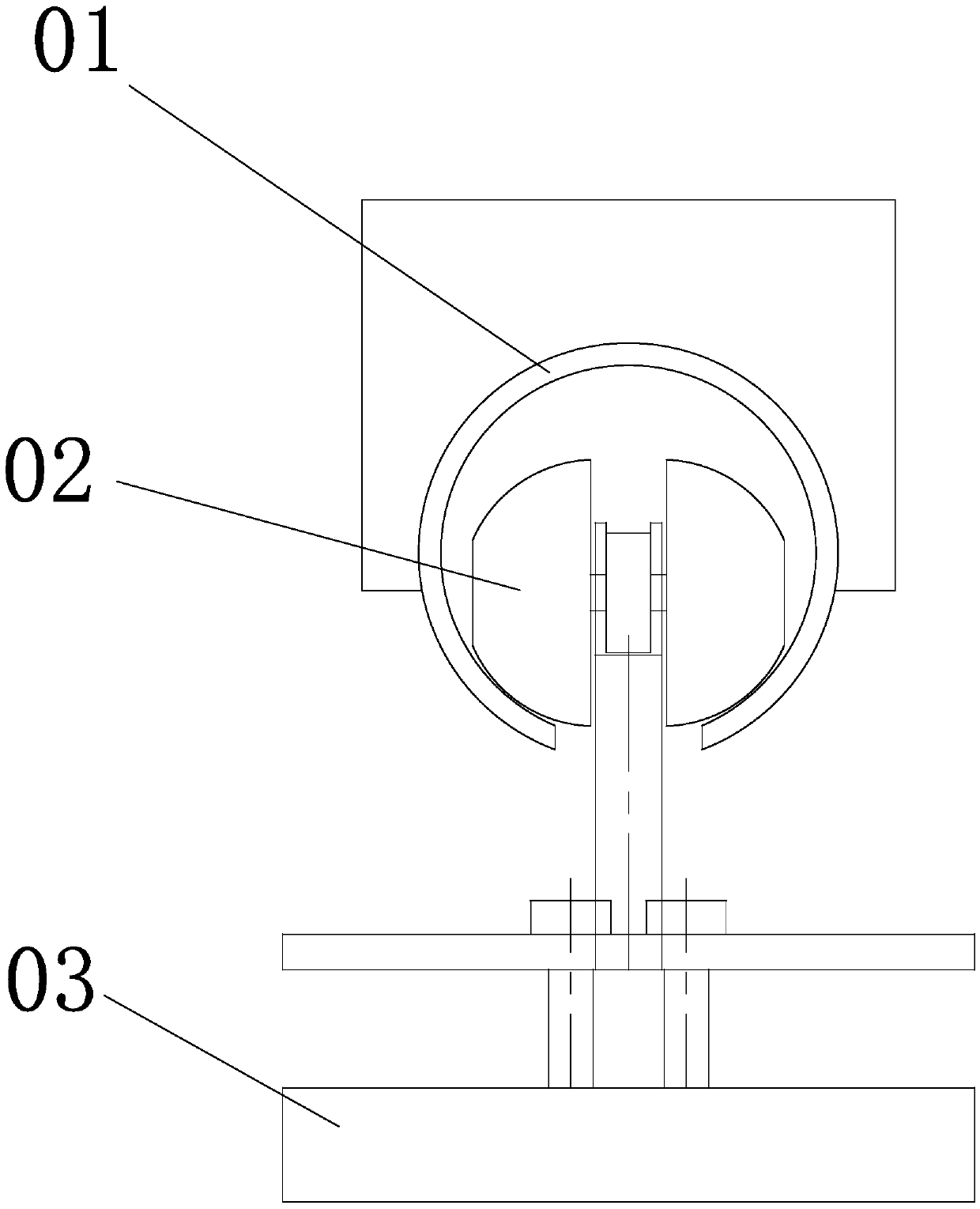

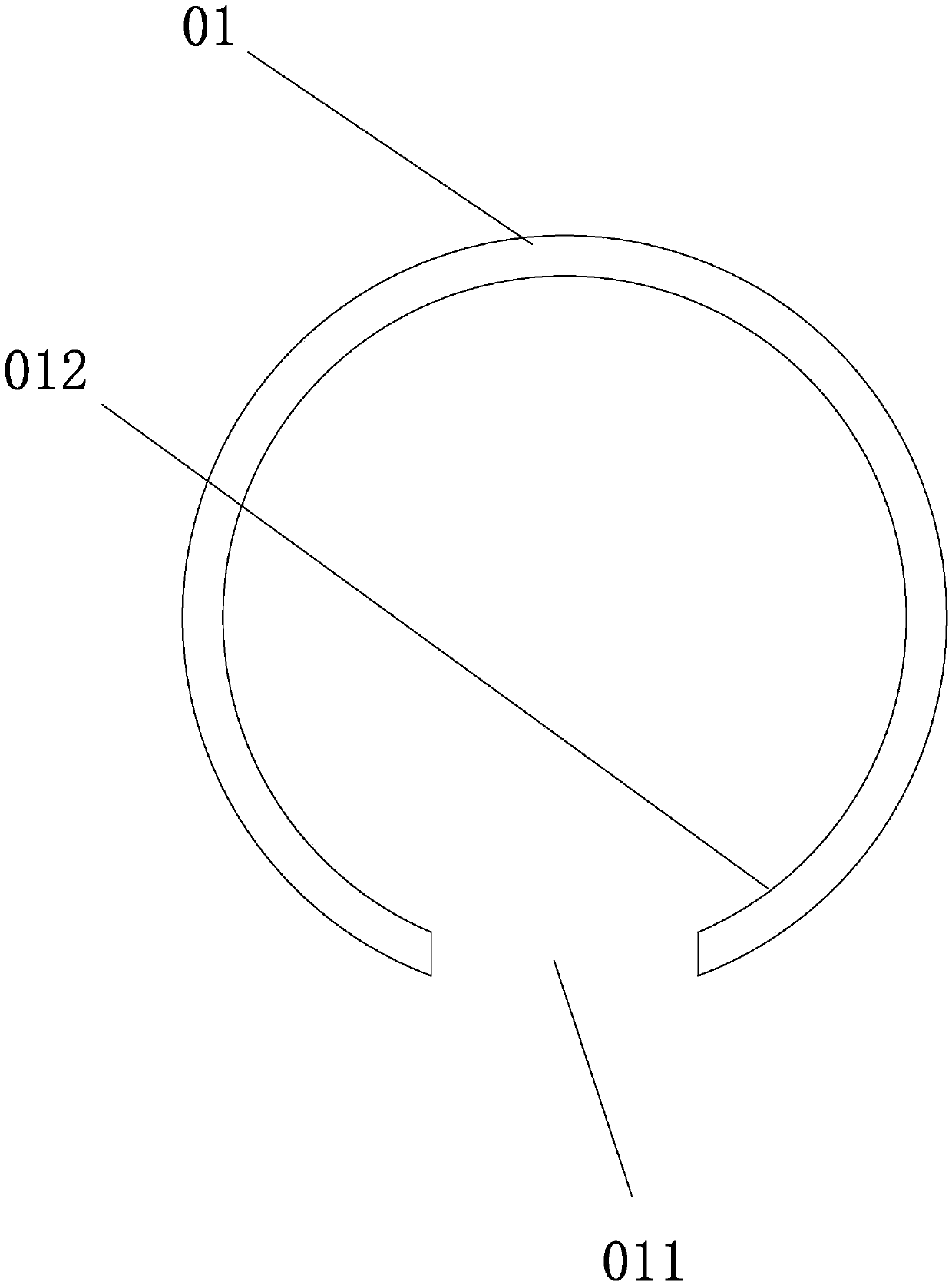

[0028] Embodiment 1: as figure 1 , 2 , Shown in 3 and 4, a closed cable trolley includes a track 01 and a tow trolley slidingly connected to the track, and the trolley trolleys are installed side by side on the track 01. The track is a tubular structure with an open slot 011 at the lower end, and the cross section of the track is a superior arc. The trolley includes a pulley 02, a central shaft 05 that is rotatably connected to the pulley, a cable saddle 03 fixed on the central shaft, and a cable 04 is fixed on the cable saddle 03. Both ends of the central shaft are equipped with pulleys, and the pulleys and the inner surface of the track form a sliding connection through bearings. The cable saddle runs through the open slot and is connected to the middle of the central axis. The inner surface of the track is located on both sides of the open slot as the first arc-shaped surface 012, and the side of the pulley is the second arc-shaped surface 021 matched with the first arc-s...

Embodiment 2

[0030] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 5 As shown, sliding balls 06 are arranged on the second arc surface of the pulley, and the sliding balls are embedded on the surface of the second arc surface. The sliding balls are located on the same surface and this surface is perpendicular to the central axis. touch. One end of the pulley away from the central axis is provided with a guide ball 07, and the guide ball is arranged coaxially with the central axis. Such as Image 6 As shown, the guide ball includes a ball body 071 and a ball seat 072 for the ball body to rotate. The pulley is provided with a guide groove 11 for accommodating the ball seat. The ball seat is slidably connected with the guide groove. The spring is in conflict with the ball seat, and the axis of the guide groove is coaxial with the pulley. Such as Figure 7 As shown, the sliding ball includes a ball body 061 a...

Embodiment 3

[0032] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 8 , 9 As shown, the track 01 is in the shape of a ring, and the pulley 02 drives the cable saddle 03 and the cable 04 to make a circular motion along the track. The whole track is surrounded by a ring shape, and the track section is in an arc shape, which can avoid the blockage of the pulley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com