Automatic deburring mechanism for magnetic shoe automatic deburring system

A deburring mechanism and deburring technology, which are applied to machine tools, grinders, and metal processing equipment suitable for grinding the edges of workpieces, can solve problems such as production efficiency and quality impact, high workload of workers, and harsh environments, and reduce Labor cost, good deburring effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and working principles, but it is not intended to limit the protection scope of the present invention.

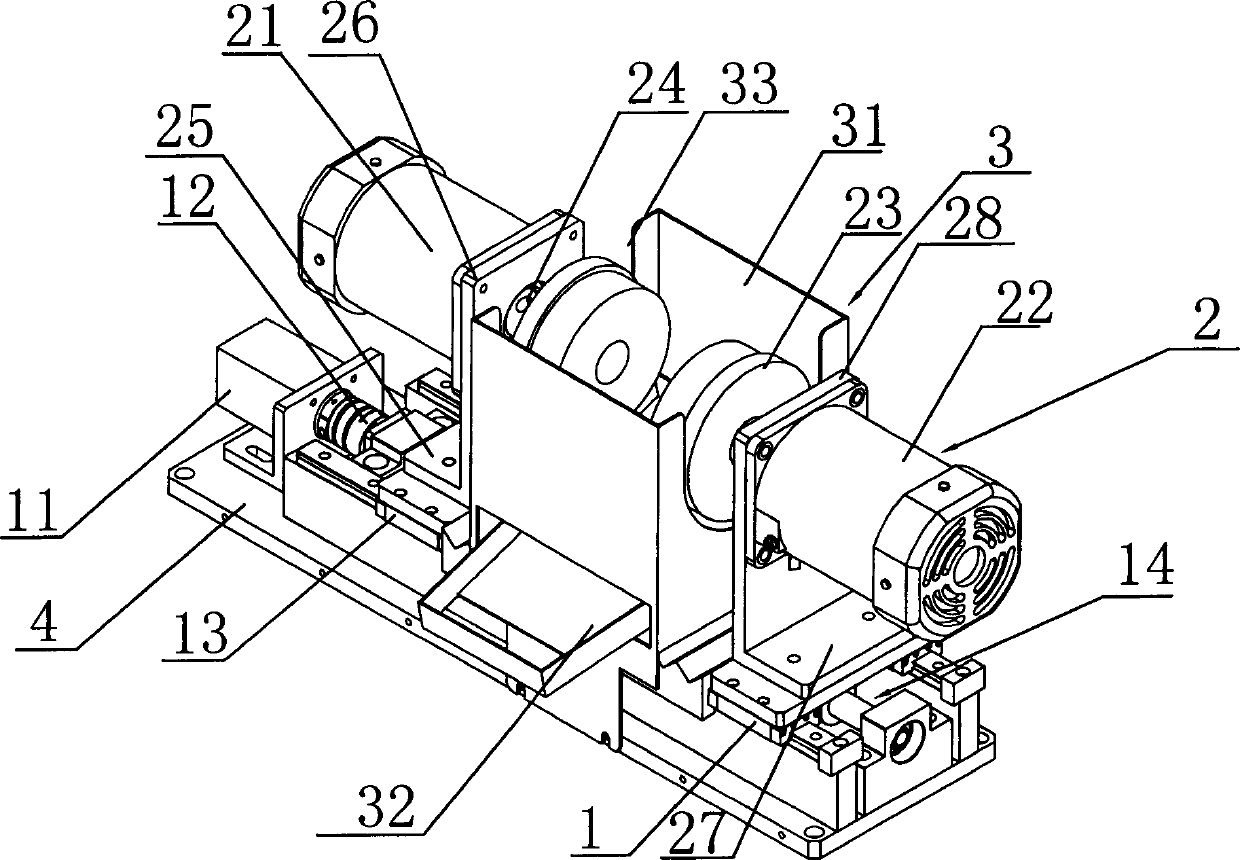

[0018] Such as figure 1 As shown, the automatic deburring mechanism for the magnetic tile automatic deburring system includes a bracket 4, a deburring device 2 arranged on the bracket 4, a servo drive device 1 is provided on the bracket 4, and the servo drive device 1 includes a servo motor 11 , positive and negative ball screw 12, positive guide rail slider 13 and reverse guide rail slider 14, deburring device 2 includes two mutually symmetrical deburring motors and a special disk brush 23 connected on the deburring motor shaft, Two deburring motors are respectively fixed on the positive guide rail slider 13 and the reverse guide rail slider 14. The two deburring motors are respectively the first deburring motor 21 and the second deburring motor 22, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com