Dissociation agent, dissociation technique, flexible display device and production technique of flexible display device

A flexible display and preparation process technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of thin-film electronic device damage, complex procedures, damage to electronic devices, etc., and achieve rapid dissociation and simple procedures. , easy to prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

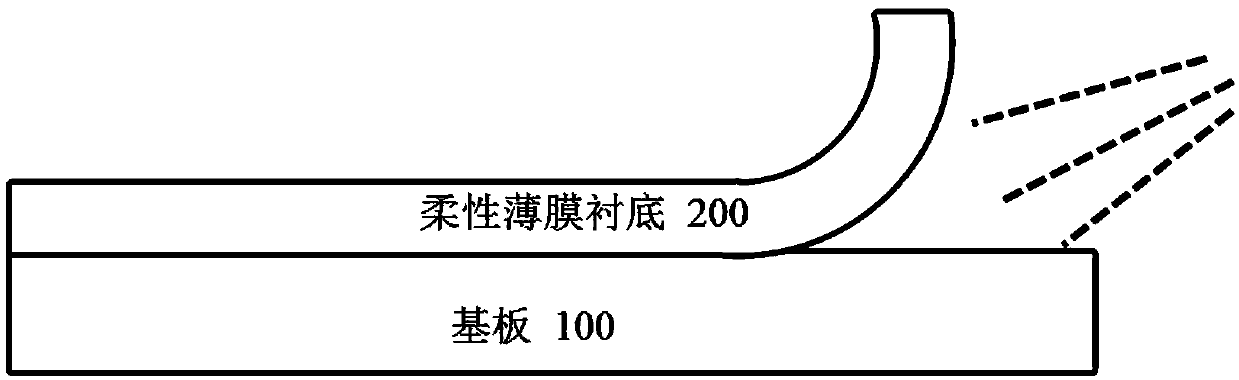

[0036] A flexible display device and a manufacturing process thereof. The preparation process is to firstly prepare a flexible film substrate 200 on the substrate 100, then prepare a thin film device on the flexible film substrate 200 to form a primary body, and finally dissociate the primary flexible film substrate 200 from the substrate 100 by a dissociating agent to obtain Finished flexible display device.

[0037] It should be noted that the substrate 100 is a rigid substrate 100 , and the substrate 100 , the flexible thin film substrate 200 , thin film devices and their preparation methods are common knowledge in the art, and will not be repeated here.

[0038] The substrate 100 may be a substrate 100 made of glass, metal, single crystal silicon or plastic, and the substrate 100 may be a planar substrate or a curved substrate.

[0039] The flexible film substrate 200 can be polyimide (Polyimide, PI), polyethylene terephthalate (Polyethylene terephthalate, PET), polyethyl...

Embodiment 2

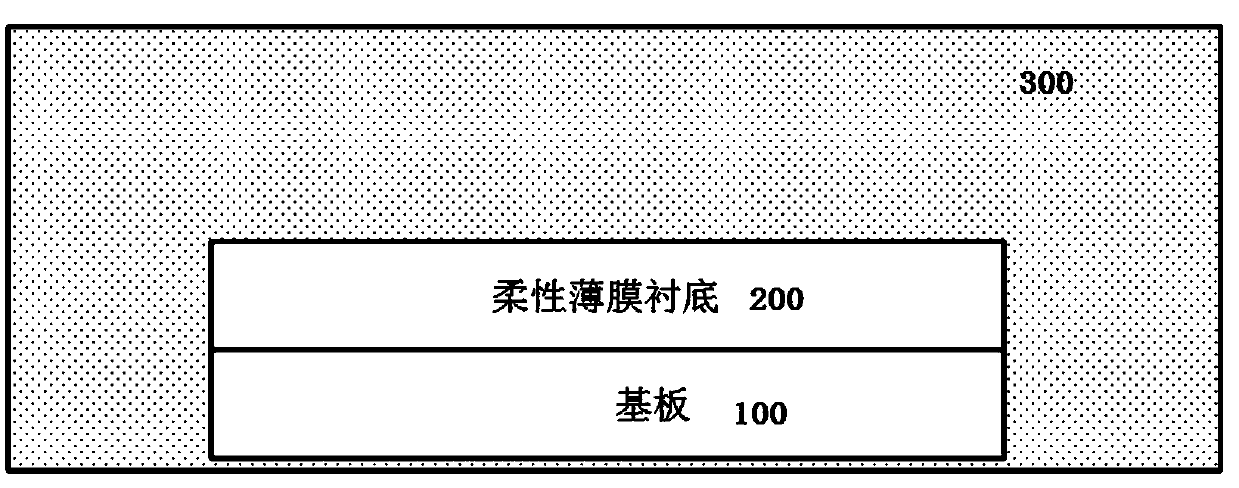

[0046] A manufacturing process of a flexible display device, the other features of which are the same as those of Embodiment 1 above, except that the flexible thin film substrate 200 is separated from the substrate 100 by means of mist diffusion. like figure 2 As shown, specifically, the precursor is put into the reaction chamber 300 filled with vaporized or atomized dissociating agent, and then taken out to separate the flexible film substrate 200 from the substrate 100 .

[0047] In this method, the gasified or atomized dissociating agent in the reaction chamber 300 penetrates into the interface between the flexible film substrate 200 and the substrate 100, and weakens the gap between the flexible film substrate 200 and the hard substrate 100 by chemical reaction. The adhesive force makes it easy to separate the flexible film substrate 200 from the substrate 100 . This method is suitable for situations where the requirement for dissociation time is not high.

Embodiment 3

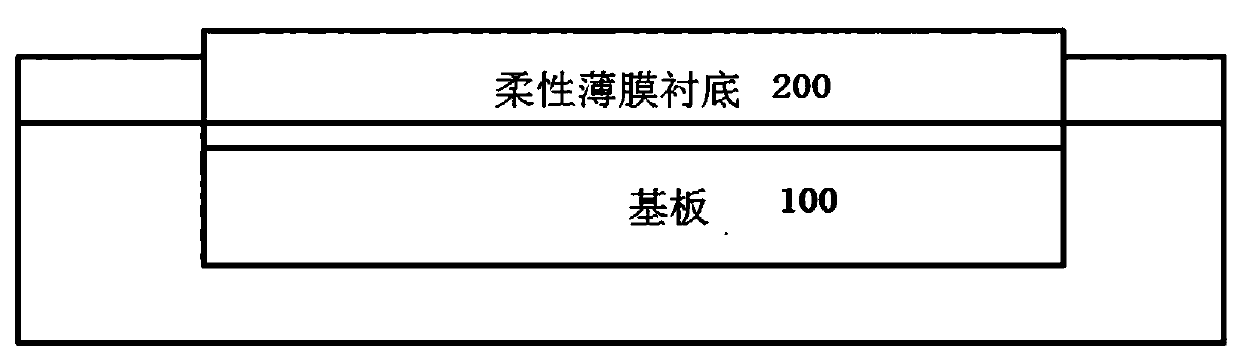

[0049] A manufacturing process of a flexible display device, the other features of which are the same as those of Embodiment 1 above, except that the flexible film substrate 200 is separated from the substrate 100 by soaking. like image 3 As shown, specifically, the substrate 100 and the part of the substrate 100 in contact with the flexible film substrate 200 are soaked in a dissociating agent solution for a moment, and then taken out to dissociate the flexible film substrate from the substrate.

[0050] In this method, the dissociating agent is soaked, so that the dissociating agent penetrates into the interface between the flexible film substrate 200 and the substrate 100, and the adhesive force between the flexible film substrate 200 and the hard substrate 100 is weakened by chemical reaction, so that the flexible film The substrate 200 is easily separated from the substrate 100 . This method dissociates quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com