Safety management method for equipment in oil depot and gas station

A safety management and safety management platform technology, applied in the field of oil depot and gas station equipment safety management, can solve the problem that the management department cannot obtain the dynamic information of oil depot and gas station equipment in time, the management of maintenance costs cannot be finely controlled, and the establishment of equipment maintenance plans is based on a single document experience and other issues to achieve the effect of improving equipment safety management level, eliminating hidden dangers of equipment safety, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

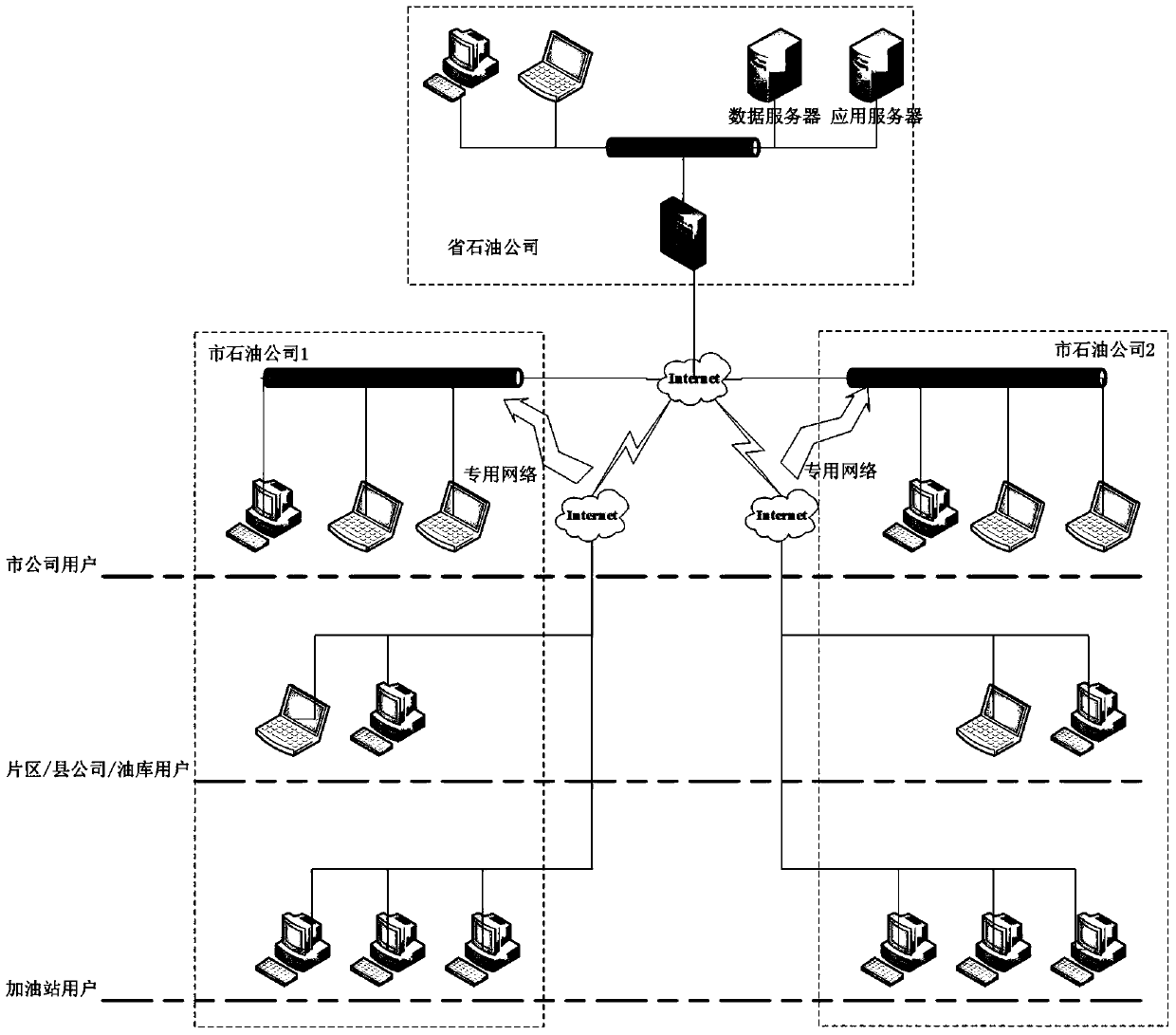

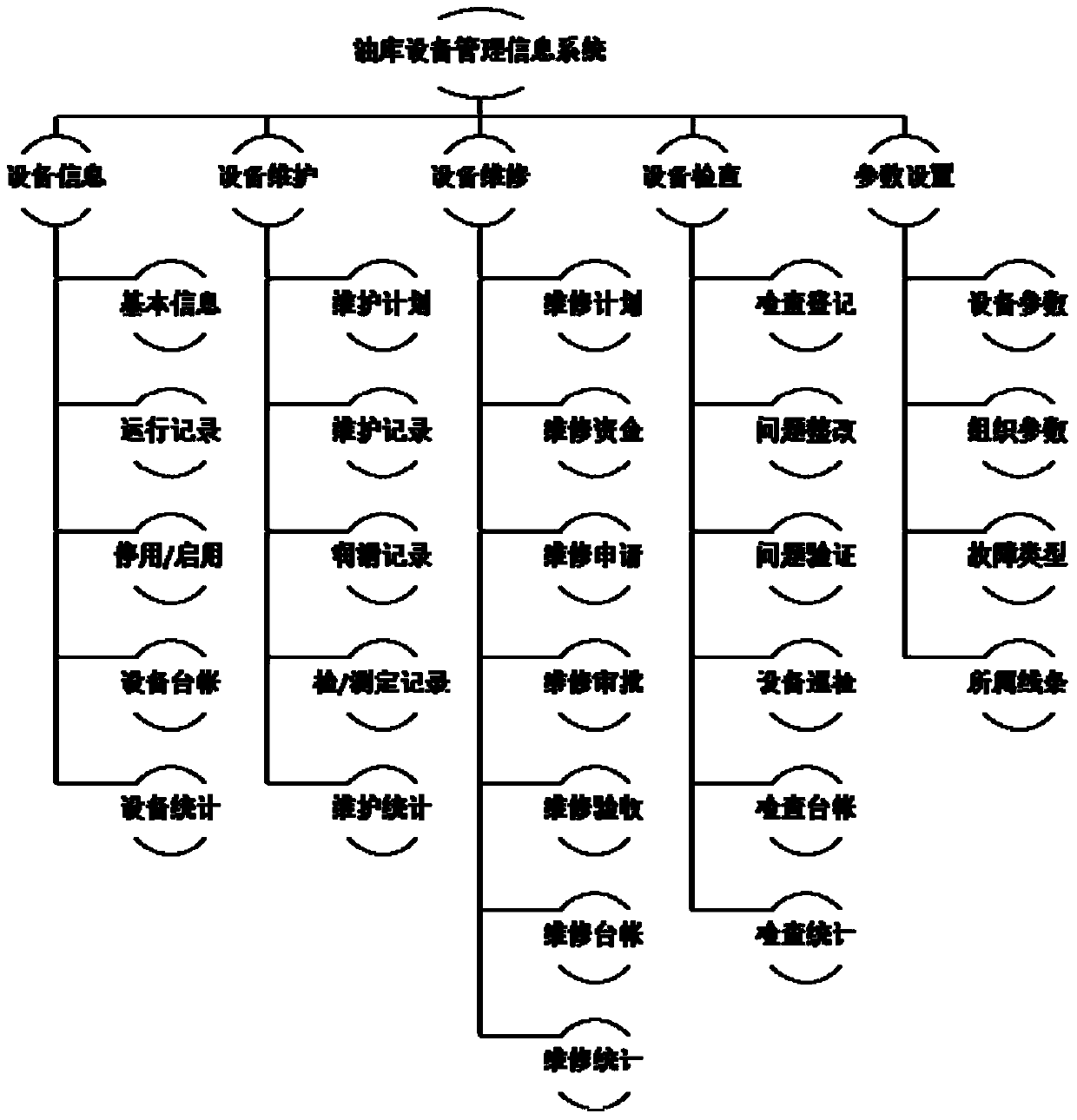

[0028] In the oil depot and gas station equipment safety management method proposed by the present invention, the user logs in to the oil depot and gas station equipment safety management platform through the Internet or an enterprise dedicated network to complete the equipment safety management work. The oil depot and gas station equipment safety management platform includes hardware parts and The software part is composed of gas stations, oil depots and higher-level oil companies. It grasps the status of various equipment in oil depots and gas stations through information technology, realizes equipment maintenance, repair, and inspection information records, and checks the closed loop of problems through the system. Management, automatic calculation of maintenance and repair plan, as well as hierarchical application and automatic distribution approval of maintenance process and maintenance funds, form the whole process management of the entire life cycle of equipment, and gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com