Copper-constantan thermocouple and preparation method thereof

A technology of thermocouple and constantan, which is applied in the direction of directly heat-sensitive electric/magnetic element thermometers, measuring heat, and using electric devices, etc. It can solve the problems of difficult preparation technology, inability to use preparation methods, and broken soldering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment discloses a copper-constantan thermocouple, which includes a thermal electrode welded by a copper wire conductor and a constantan wire conductor; the diameter of the copper wire conductor is 0.04mm to 0.2mm; the constantan wire The diameter of the conductor is 0.04 mm to 0.2 mm. Moreover, the external diameter of the test end of the thermocouple disclosed in this embodiment is less than 1mm. It can meet certain specific purposes, such as temperature test of tiny sample chamber, transient test of rapid temperature rise, etc. to complete accurate measurement.

Embodiment 2

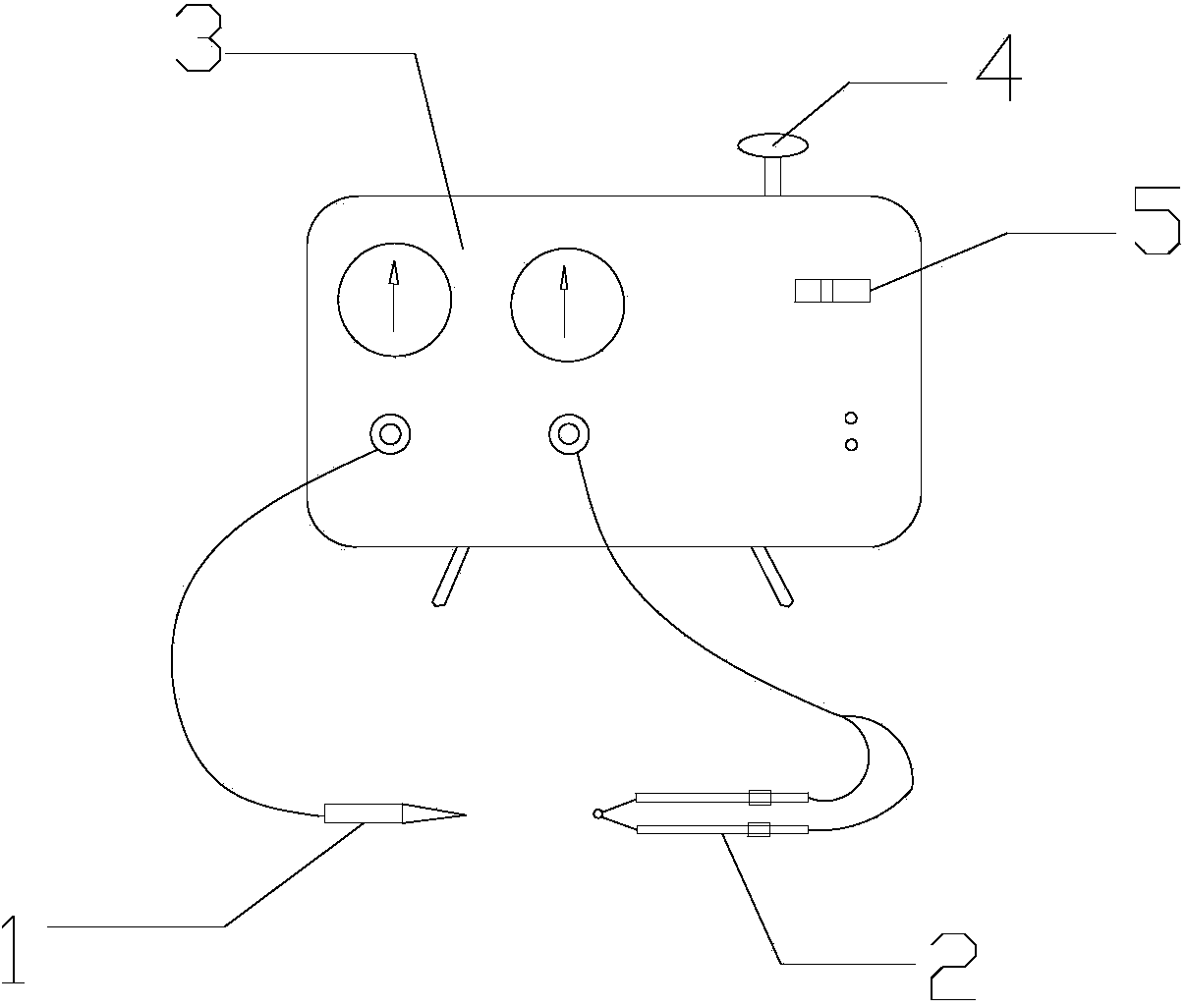

[0032] Such as figure 1 As shown, according to another embodiment of the present invention, this embodiment discloses a method for preparing a copper-constantan thermocouple, the main equipment used in this embodiment is DC arc welding equipment, such as figure 1 As shown, it mainly includes a device body, which is provided with a rectifier 3 and a pressure regulating handle 4, and a switch 5 is provided on the device body for starting and closing the device. It is preferred that the welding rod in this device adopts carbon rod 1, Weldment 2 is composed of copper wire and constantan wire. Wherein the diameter of the copper wire conductor is 0.04mm to 0.2mm; the diameter of the constantan wire conductor is 0.04mm to 0.2mm. Preferably, the contact end between the carbon rod and the weldment is provided with a tip structure. Specifically, it can be prepared by using the carbon rod in the waste No. 1 battery and grinding it into the shape of a pencil head.

[0033] In the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com